The sense of sight or vision is perhaps the most influential among the five senses. Spectacular, marvellous, magnificent, splendiferous, wow, etc.; there are many verbal expressions to convey the appreciation for the beauty visible through our eyes. Our fascination with the joys that this ‘sense of vision’ can evoke is the basis for designing unique and awe-inspiring envelopes for the buildings The façade industry has gone through many evolutions over centuries.

The industrial revolution has played a major role in bringing up the best in the façade industry and each of its segments. Between the start of the usage of glass in large areas of the façade in circa 16th century and the era of digital manufacturing in the 21st century, many revolutionary developments have been witnessed.

Functionally, a façade separates the indoor environment from the outdoor. So, a façade and its components should be designed to withstand environmental factors like wind pressure, heat and cold, entrainment of water and air, harmful UV rays from the sun, etc. Due to the supremacy of the ‘sense of vision’, the façade designers became the driving force behind modern buildings.

The compelling need to strive for the best of shapes, forms, colours and textures combined with innovative products and methods paved the way for the realization of complicated designs and detailing. Advancements in designing facilitated by modern computer-aided designs of the building envelope created requirements for customized hardware as well. The global markets for the hardware industry in due course have easily coped with the demands of façade designs by using innovative materials and methods.

Facade Systems

Modern buildings are mainly cladded with glass, aluminium, stone, wood, GRC, GFRC, etc. The function of the building, area of application, environmental parameters, cost factors, etc. decide the type of façade to be implemented. The integration of glass and aluminium is abundantly used due to its multiple advantage and availability. Transparent panels and openable panels were also considered essential requirements. Stick systems and unitized panel systems are commonly used by designers in the field of construction.

Windows/Doors

Openings in the façade are required to allow interaction between the indoor and the outdoor environment in a controlled manner. Traditionally, punched windows were used to provide interior and exterior views, and ventilation, and regulate the transfer of humidity and sound. Door openings are required for secured entry and exit of men, materials, vehicles, etc. Adjustable window openings are essential to ensure safe indoor climate conditions. Manual or automatic operable windows are commonly used in current times.

Hardware Of Facade

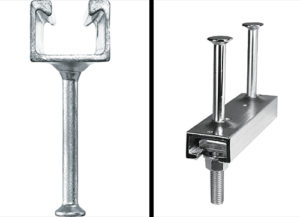

- Embedded U channels

Different façade systems require different hardware. For unitized panel systems, embedded U channels are used to connect the façade to the parent building. The load from the façade is transferred to the connected edges of the building through “U” channels.

Fixity of this channel is generally determined by the strength of the concrete, embedment depth, mechanical properties of the channel, method of installation and workmanship. It is commonly observed that the channels are displaced or misaligned during the concrete pour. The top of the channel is required to match the top surface of the slab. Bad workmanship can lead to the channel being covered with concrete. Construction field engineers should therefore ensure that the channels are restrained properly before the concrete pour.

Pre and post concrete surveys should be made mandatory. Extra care should be ensured during the use of needle vibrators near the channels during the pouring of the concrete. Negligence should be avoided as well as the urge to be overconfident. In case of mishaps, one needs to overcome hesitance to seek expert advice and ensure corrective measures. The mechanical and chemical properties of embedded channels should also comply with the specifications. Durability is a key factor to be considered while choosing the right product. Necessary tests should be conducted as per the project specification before continuing with successive activities.

- “T” bolts

T bolts are used to connect plate anchors to embedded channels. T bolts should be designed to resist the support reactions from façade design loads like Embedded U channels (Image courtesy – Hilti and Halfen) self-weight, wind, seismicity, thermal and occupational loads. High-strength T bolts of the same manufacturer of U channel should be used to ensure maximum efficiency.

T bolt and U channel provide a tapered locking connection. This system allows flexible connection without the drilling process. While selecting the T bolt and channel, one must ensure that the fire rating requirements are met. High corrosion resistance is considered extremely important.

- Brackets

Unique systems of brackets are required for stick and unitized systems. Brackets are connected to embed U channels by using T bolts mentioned earlier. Brackets should be designed to withstand structural stresses from the façade. Slotted holes of the bracket help to accommodate the permitted deviation in the plump of structural elements in different levels. Metallic covers may be used to protect the connection assembly from construction debris or impurities. Strict quality control should be assured during the installation of façade supporting hardware.

There are higher chances of overlooking these assemblies as a result of access restrictions to the slab edge due to certain safety concerns. Remember, the density of glass is more than that of concrete. So, if the façade panel is disconnected from the slab edge, it could lead to major accidents.

Hardware Of Windows

Designers decide on the variety of windows based on various parameters. Horizontal sliding, vertical sliding, side hung casement, top hung casement, bottom hung casement, tilt and turn, pivot, bi-fold and louvered are some of the different types of windows in the modern market. The type of hardware differs according to the type of the window. However, irrespective of the type of windows, the common parameters to be considered are safety, security, durability, ease of use, and aesthetic value.

- Fasteners

Screws, bolts and expansion shields are the basic components required for the installation of windows. Ideally, the finish of exposed fasteners should match with the finish of connecting member. One must ensure the compatibility of fasteners with the material it passes through. The threaded steel fasteners should comply with Indian standard IS 1367 (Part 3). The numbers, spacing and location have to be pre-determined/ designed. Tests prescribed in the code should be conducted.

- Locks and Latches

Sliding window locks and latches are normally operated with fingers. Space in the latch slot to insert fingers must be verified for the convenience of different age groups and different physiques. Ideally, the RAL color code of the lock should match with frames. Numerous options are available for the handle and lock of hung windows. Operating a window is a day-to-day affair. Functionality and ease of operation should be the prime factor rather than pure aesthetic appearance.

At times a sleek design may not be durable. Actuation of the handle facilitates the closing and opening operation of the windows. Motorized operation is also possible if required. Side-hung windows can be fitted with simple turn handles or handles with lock keys. Aluminium or stainless steel hardware is ideal for the coastal environment. Powder-coated finish matching with the frames or metallic plating like chrome, satin, brass, nickel or stainless steel finish or anodized finish are the major finishes available in the market.

Hardware Of Doors

The hardware of aluminum doors is similar to that of the windows. Nevertheless, the choice should be based on the function of the room. “Security” is the word that comes into our mind when we think about the doors. Hence, door hardware should be selected carefully by considering the function of the room to be accessed. Multipoint security locks and key cylinders should be selected from reputed brands to avoid the malfunction of locks. The reference code of the Indian standard for door handles is IS 4992: 1975. The major hardware of doors are:

-

Innovative façade systems – Ziraat Bank Headquarters Complex, Turkey Lever/Pull/knob handles

- Push plates and Kick plates

- Door guards

- Door viewers

- Panic bars

- Locks

- Hinges

- Door closers

- Floor springs

- Automation Accessories

- Flush bolts

- Latches

Every developer should pre-plan their hardware selection by preparing a hardware schedule in advance. Sample boards of each type of door should be made available from the manufacturer/ supplier. The matrix should include the type, style, function, size and finish of each item. Similarly, the name of the manufacturer, location of use, and keying info should be indicated. Master keying must be decided in advance. The separate master key may be prepared for the main tower common areas, utility areas, mechanical areas, electrical rooms, machine rooms, etc. Also, one must ensure attic stock of a minimum 5% of each component for future use. Manufacturer warranty should be ensured.

Globalization, market competition and innovative materials have given numerous choices to customers to select the right hardware that suits their requirements. Good brands have been concentrating on continuous improvement of quality and increasing the product range to ensure the sustainability of their market share.