When you walk towards the majestic Oval Room at The Mansion, your eyes will undoubtedly stop at the striking bronze-shimmered glass panels enveloping this beautiful architecture. What started out as a wildly imaginative design concept, now stands as the country’s largest metal-incorporated glass façade. But there’s more to these glasses than their spectacular appearance – they also very effectively diffuse sunlight and provide a massive reduction in solar heat gain, two inherently important but often overlooked requirements in such free-standing structures. This case study elaborates on the design features of these glass panels and its journey from concept to reality.

Hyatt Regency Delhi’s Oval Room at ‘The Mansion’ is its newest event space designed to host conferences, seminars, weddings and corporate meetings. Spread over 1,400 sq m, it is an opulent pillar-free space that can accommodate up to 1,000 guests with an open kitchen setup that translates Panelslive cooking into a theatrical experience, a first for New Delhi. The high ceiling is adorned with contemporary fibre-optic chandeliers and mood lighting. But perhaps most of all, its 3.8 m meter, stylish glass panels embellished with a bronze mesh serves as the highlight, flooding the hall with natural sunlight and still reducing glare by over 65 per cent.

The Concept

The Oval Room at ‘The Mansion’ was conceived as a new event-space structure in the Hyatt Regency Hotel, New Delhi’s oldest five-star property. As Shiv Jatia, Chairman and Managing Director of developers Asian (North) Hotels puts it, they needed “an energising event space situated in the busiest location in New Delhi, showcasing Hyatt Regency Delhi’s inspiration to create innovative ideas”. A courtyard overlooking the main building was the selected location and BauerLatoza Studio from Chicago, renowned for its work in architecture,

planning, historic preservation and hospitality design was appointed as the principal design architect. From the onset the intent was clear: the building needed to create a never-before-seen statement and everything from the design to the choice of materials had to be absolutely unique and of the highest order.

The Team

CR Narayana Rao Architects from Chennai was signed up as the local architect and the interior design work was entrusted to Hirsch Bedner Associates from Dubai, with consultation from designer Michelle Evans, DPA Lighting from UK and MKA from Seattle. Chennai-based Mahesh Arumugam from Meinhardt Façade was enlisted as the façade consultant to supervise the technical feasibility of this experimental structure and the Bengaluru-based Geodesic Technologies was entrusted with the execution of both, the steel structure and the façade. Future Architectural Glass LLC from UAE was appointed as the glass fabricators due to their past extensive experience in executing complicated and large glass assemblies.

The Façade

Tim Vacha and John Azarian from BauerLatoza Studio set about designing a grand space that would be enveloped with something unique, standing out from the ordinary. Various concepts kept playing to create a “live” façade that was both dynamic and elegant with subtle variations throughout the day. The challenge was to allow a high light transmission to create a bright interior space without the undesirable and characteristic Delhi sun glare and at the same time give a unique sheen to the envelope. Conventional glass tints, coatings and frit patterns would look flat and create either total transparency or part-opacity, both unacceptable. Only a mesh structure would solve the conundrum – and the challenge now lay in integrating this material into a glass assembly.

The Materials

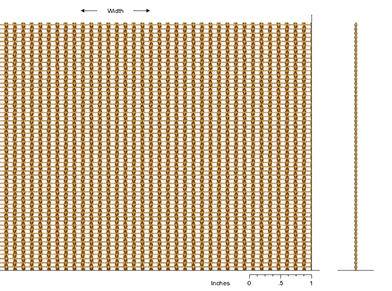

Post a lengthy and painstaking selection process, Mandarin – a woven bronze metal fabric was selected from GKD-Gebr Kufferath AG based in Germany. Mandarin is an intricately woven and flexible metal mesh made with pure bronze strips in its natural lustre (see inset for details). The small opening size of 37 per cent does a wonderful job of diffusing direct sunlight and still maintains a relatively high light transmission of up to 41 per cent. The depth also creates a beautiful three-dimensional effect giving the façade the dynamism that was originally conceptualized. This mesh now needed to be protected within a laminated glass assembly for longevity and ease of maintenance. Ordinary clear glass has an intrinsic subtle green tint that would blight Mandarin’s natural bronze sheen. To counter this, a low-iron ultra-clear glass was selected to effectively preserve its appearance. PPG’s Starphire® (USA) ultra-clear glass was finally chosen owing to its very high light transmission (91 per cent) and colour-rendering index (99 per cent) and almost negligible residual colour. And finally, the glass assembly was to be fixed on the main steel structure with Schueco systems from Germany.

The Process – From Design to Implementation

Rewind to March 15, 2013, in CR Narayana Rao’s Chennai office where all the key design, production and installation firms are deliberating over the challenge of integrating metal and glass together. Can we combine the lustre that only metal can offer with the robustness and transparency of glass? This was something never tried before in India at this scale and the very strict project timelines demanded quick testing and specification finalisation to facilitate production and installation.

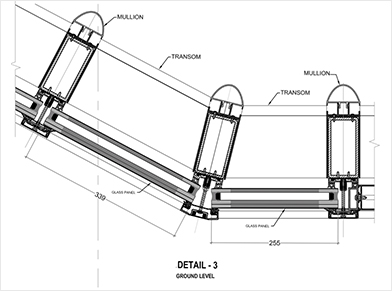

To cater to the stringent HVAC demand of a low U-Value, the outer laminated panels were converted into an insulated glass unit with an extra inner clear glass lite that also facilitated vastly enhanced acoustic insulation (STC of 44 decibels) and better thermal comfort.

The choice of interlayer was critical to ensure perfect adhesion and durability. Conventional polyvinyl butyral (PVB) interlayers used to laminate simple glass assemblies would not work since their adhesion with metals is extremely poor and a better interlayer technology was needed to ensure the design’s success. DuPontTM’s SentryGlas® ionoplast interlayer technology was then considered. The chemical composition of SentryGlas® allowed for metal-to-glass assemblies due to its substantially superior flow rates ensuring that all areas of the mesh were comprehensively covered during the lamination process. The clearer appearance and higher Young’s Modulus (300 MPa) and tensile strength (34.50 MPa) served as added benefits compared to PVB interlayers and imparted a strength that could be compared to that of a fully bolted structure. Still, extensive testing was required to ensure that this experimental façade yielded the desired results.

The focus now shifted to finalising the glass and interlayer thickness. An important consideration was the higher-than-normal glass height of 3.80 m which could result in the units buckling due to self-weight and consequently distorting the optical clarity of the integrated mesh assembly. Also, the right interlayer thickness was needed to ensure that the “gaps” in the mesh were perfectly filled and no air pockets were created which could result in adhesion failure over the lifetime of the unit. With a wire diameter of 3 X 0.50 mm for the cables and 0.50 mm for the rods, the total mesh thickness was calculated at 1.30 mm. After much deliberation, a 1.52 mm SentryGlas® interlayer was approved on either side of the mesh and two 8.00 mm heat-strengthened low-iron glass lites were selected to encapsulate this assembly, giving a total unit thickness of 43 mm.

Post some very extensive stability, integrity and water penetration tests, production commenced at Future Architectural Glass’ UAE facility. Every step of the manufacturing process needed to be carefully monitored to ensure that quality levels were maintained and adhesion values were not compromised. Extensive changes in the lamination process and auto-clave cycles were essential and after some experimental manufacturing, the final recipes and processes were frozen. Says Firoz Kachwala, director of Future Architectural Glass, “The project presented both a challenge and an opportunity to create a unique glass product. It had many firsts to its credit: glass assemblies with new materials, new lamination process technologies and new testing procedures. The extremely high cost of raw materials put us under tremendous pressure to get things moving quickly and with very constrained margins for rejections.”

The units were assembled and shipped in final form to the hotel site from Dubai port and erected on a massive steel-fabricated structure constructed by Geodesic Techniques. Impressively, the entire structure was completed as per the expected timelines and the result today stands truly as one of India’s modern architectural statements.

GKD MANDARIN MESH

Material: Bronze

Type: Flexible, two directions

Open Area: 37%

Weight: 0.50 lbs/sqft

Max. width: 12’

Visible Light Transmittance: Min 0.23, Max 0.41

Visible Light Reflectance: Min 0.25, Max 0.33

Solar Gain Coefficient (SHGC): Min 0.18, Max 0.30

QUICK FACTS

Project: The Oval Room, Hyatt Regency, New Delhi

Developer: Asian Hotels (North) Limited, New Delhi

Design Architect: BauerLatoza Studio, Chicago

Indian Architect: CR Narayana Rao, India

Interior Design Firm: Hirsch Bedner Associates, UAE

Façade Consultant: Meinhardt Façades, India

Processor: Future Architectural Glass, UAE

Civil Works and Fabricator: Geodesic Techniques, India

Glass: PPG StarphireTM Low-Iron Glass, USA

Mesh: GKD Mandarin Mesh, Germany

Interlayer: DuPontTM SentryGlas®, USA

Fabrication System: Schueco, Germany

Total Glass Panels: 503

Total Glass Area: 1,056 Square Meters

Period of Construction: May 2013 to December 2013