When loss to human life and property bring about grief, we invest our resources to ensure such losses do not occur again. For decades, countries and jurisdictions have been writing and evolving guidance documents (building codes) to build-in safety measures in construction to prevent loss to life.

These codes give requirements ranging from structural requirements, fire initiation and growth prevention requirements, and even requirements for the design of plumbing systems to ensure the health of building occupants. The development and implementation of such codes in many countries is usually driven by manufacturers of products who believe very strongly in prevention of loss. The ethos of such companies drives them to aid the adoption and localisation of such codes written internationally.

Fire Safety Codes

They are guidance documents which usually divide construction of different types of buildings by grouping them into what is called occupancies (the occupants and use of the building) as it helps to predict the behavior of people if there is a fire. Fire Safety Code requirements provide the framework and boundaries to architects and consultants for designing buildings.

The codes also help:

a) Material suppliers to produce standard materials

b) Contractors to objectively price and plan for construction work, and

c) Authorities and regulators to objectively evaluate how fire safety will be implemented for buildings which are competing to differentiate themselves from other buildings.

For the majority of the codes followed in the world, a two pronged approach for fire safety is commonly followed.

One, they aim to prevent a fire from initiating and spreading beyond the area where it began (passive fire protection).

Two, to have measures in place to detect, and if possible, suppress a fire (active fire protection).

As the use of combustible materials in construction has been increasing over the past few decades; fire rated doors (and wall and roof systems) have been enabling the containment of fire within a compartment until the fire brigade reaches the building and the occupants can be safely evacuated to prevent a loss of life.

What Are Fire Doors?

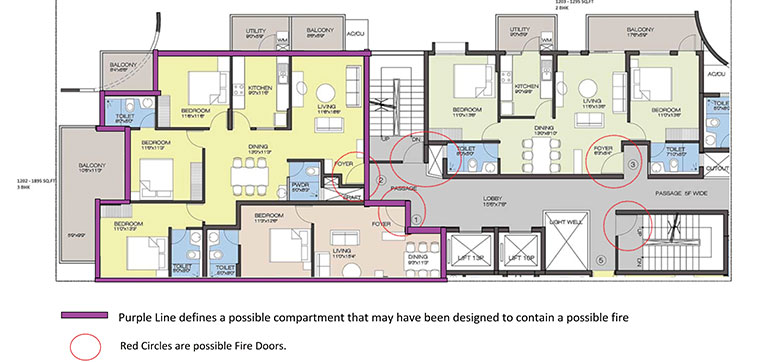

Passive fire protection creates a strategy of compartmentalising the occurrence of a fire within a small area so that the fire does not spread rapidly. Figure 1, explains how a compartment can be designed on a typical floor plan for an apartment building. The solid purple lines show the area where the walls might be designed to contain the fire and the red circles show doors that might be required to be fire rated.

The words ‘might be’ are used as the type of occupancy (where the building is constructed and who occupies it) defines what the fire strategy is designed and how it is deployed.

A fire door assembly is a complete set of door-frame, door leaf, door-hardware and associated fixing details. It is this complete combination that need to contain a fire in a room/compartment.

As per a published report on “analysis of changing residential fire dynamics” by Underwriters Laboratories, experiments show that living room fires now have flash over times of less than 5 minutes when previously, they used to be around 30 minutes. The time between the initiation of a fire (dropping a burning matchstick or a cigarette stub as an example) to the time when major combustible items like sofa or mattress, etc. are burning creating high temperature and pressure is defined as a flash over time. Beyond flash over time is when it becomes very challenging to control and suppress the fire.

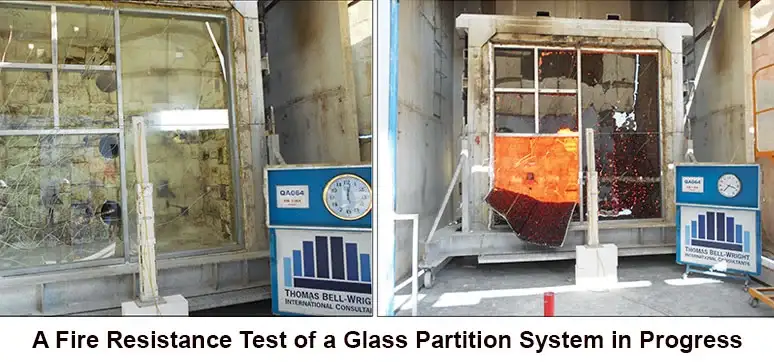

To validate the effectiveness of a fire door assembly, such a condition is replicated in a fire testing furnace. Figure 2 shows a fire resistance test of a glass partition system in progress. Here you can see the inside of a fire testing furnace.

Testing A Fire Door Assembly

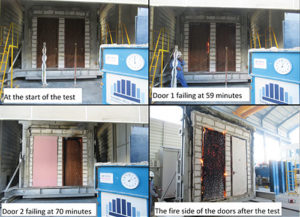

Testing laboratories need to be able to simulate the conditions define din fire test methods repeatedly. For fire doors, these test methods could be as per the requirements given in: EN 1634-1; BS 476 -22; ISO 3008; UL10B; UL10C; NFPA 252, etc. An inexperienced laboratory could conduct a test whose results are not representative of the test method and hence not useful. When a fire door assembly is installed in a laboratory, a large number of details are captured and documented. Figure 3, shows typical installed doors in a test frame with images of some of the information captured. Figure 4, shows doors during and after a fire resistance test.

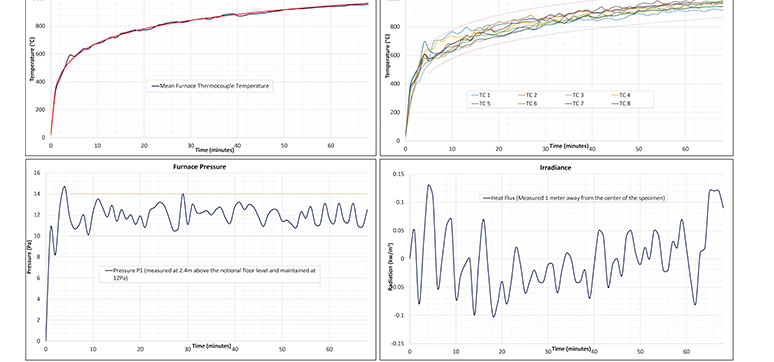

A fire resistance test validates the capability of a fire door assembly design (material selection and process) to withstand and contain a fire for a given duration in minutes or hours. Different test methods vary in a few aspects like the rate at which temperature increases (time-temperature curve), pressure increases or is maintained, etc. Figure 5, shows some of these parameters. But having successfully conducted a fire resistance test on a door assembly does not mean that all the doors produced by the manufacturer will be made to the same requirements, and therefore, offer the same fire resistance capabilities.

Understanding Reliability Of Quality Assurance Tools

ISO 170652 and ISO 170673 provide the guidelines to third party certification bodies to write their internal processes on how to check manufacturers’ capability to repeatedly manufacture products (fire doors) that perform to (fire resistance) test standards.

Product certification gives the confidence that a product fulfills specified requirements. Certified products are manufactured by a given factory under an audited quality assurance and control process which has been approved by an impartial and independent organisation called a certification body. The ongoing production is subjected to surveillance audits, giving confidence that the certificated product continues to fulfill the product requirements.

Figure 6, is a table from ISO 17067 which gives the tools that a certification body uses to check the quality assurance processes of manufacturers which are used for producing the certificated product. The product certificate is issued and is listed in a publicly accessible listing directory. This is called Certification and Listing. www.tbwcert.com is an example of such a directory.

Using Fire Door Certification Correctly In Construction

Certification and listing provide a real quality assurance mechanism as compared with a test report (which only shows one of the designs submitted by a manufacturer for a test passed a test).

How to use certification and listing for quality assurance of a construction project?

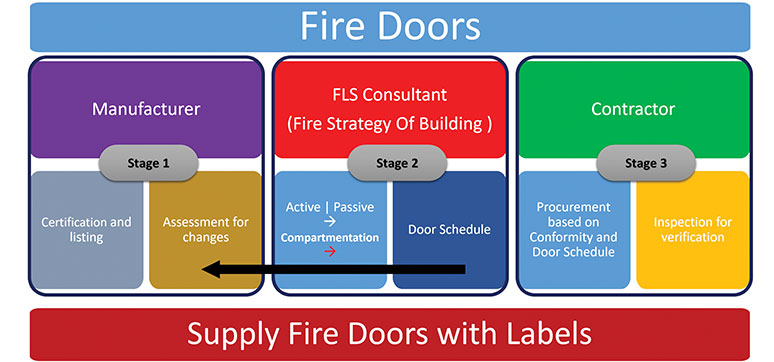

Figure 7, shows three main stages of the supply chain of fire doors.

Stage 1

Door manufacturers reach out to certification bodies to test and list one or more door-set designs. Typically, a door manufacturer will create a combination of 2 or 3 door sets to prove to a buyer (architect/ contractor/owner) that he can manufacture doors which can resist, for example, 60 minutes and 90 minutes of a fully developed fire. To do so, a third party certification body accredited as per ISO 17065 will witness the manufacturing of the sample doors which will be tested.

Such doors carrying markings to establish trace ability are then fire tested in a laboratory having an ISO 17025 accreditation (to demonstrate that they have competence in testing). Once tested, the certification body will start auditing the manufacturer’s internal quality assurance mechanisms to verify that that they can repeatedly ensure the same materials are used and processes are followed, which were used when the specimen door, which passed the fire test, was manufactured. This results in a listing of the manufacturer and product in a public directory where their door-set designs and manufactures address are listed for interested parties to verify their compliance.

Stage 2

This happens at the project level where a design consultant/fire & life safety consultant designs a ‘fire safety strategy’ for a given building. This is a document which aims to cover all possible fire risks scenarios by design features. A key part of such a document is the passive fire protection features which are ensured by the properties of materials to be used to build walls, partitions, doors, carpets, Internal finishing material, etc.

Refer to Figure 1, of a typical plan showing possible compartmentalisation. Such a plan along with fire safety strategy can result in a schedule of doors which needs to be rated to resist fire for specific duration’s. This door schedule is often the tender document where the door manufacturer bids, and it contains a list of door dimensions, constraints on hardware and the numbers to be supplied, and of course the fire rating requirements. This is a crucial stage as the door manufacturers need to submit evidence to buyers that the doors they will supply, will meet the same specifications as the ones which they proved by testing and listing on the certification directory.

Often the change in dimensions or hardware form a combination which has not been tested and listed. Now the manufacturer submits the proposed designs of the door sets to their certification body who may be able to technically assess, using past test data, that the new combination/ design will also be able to resist the fire without having to re-test it. It is very common that certification bodies need to re-test to give that assurance. Buyers need to be aware when signing off purchase orders: if there is a mismatch here, the buyer is taking on the risk and liability of a potential loss of life of people in on them.

Stage 3

The contractor and overseeing consultant needs to be assured of the procured fire doors. Fire door labels (see Figure 8) are a common tool to provide the assurance between products which have left the factory and those which reached the construction site. Certification bodies take several measures (described in Figure 6) to ensure that the labels issued for trace ability are accurate. These labels are usually put on the doors before the door-sets leave the factory. These labels, along with the manufacturer’s installation guidelines, need to be checked and followed properly by the contractor and the overseeing consultant. If not, then they are assuming the responsibility for any potential fire accident including loss of life.

Readers of this article should be able to understand the genesis of building codes and fire safety strategies. The note also aims to provide a better understanding of how fire doors (which forms an integral part of passive fire protection) are tested and certified, and how they need to be correctly selected and purchased. In the light of the recent fire tragedy in Surat, India, this note aims to increase the knowledge of readers to distinguish between the purpose of a test report and the utilization of certification and listing. When used properly, such knowledge acts as the tool to bring about a higher degree of life safety.