For the general public, it is unimaginable how much effort, skill and know-how is required nowadays to fill a hole in the wall with any window or door frame. There are numerous vital, virtually unknown steps, applicable to all frame materials before a window or door frame can be actually manufactured and installed.

In the new build market, most uPVC window companies when receiving an inquiry or an invitation to tender for a sizeable window and door contract fall into a state of euphoria and excel in providing comprehensive computer-generated quotations almost instantly. In the new build market, price matters foremost but surprisingly after the first price submission, questions like “Do the frames cope with the local wind pressure?” or “What hardware has been quoted?” lead most of the time to a re-submission of the prices because the interpretation of the fabricator and the expectation of the architect/Feature contractor sometimes differ. Tender clauses or specification pointers like the fame rigidity/strength shall comply with IS 875 – 3 wind loading for the location or hardware shall be corrosion resistant to BS EN ISO 9227 and BS EN 1191 life cycle tested to 20.000 cycles, will safeguard the client and will automatically enable the fabricator to offer a solution based on performance instead of price. India is not alone, competitive frame prices are being requested/demanded all over the world. Succeeding with fenestration products in any new build market is primarily based on “getting it right, first time!”

In the replacement retail market, every uPVC window company and uPVC door manufacturers like Encraft UPVC Window India and Fenesta Windows & Doors has its own comprehensive window and door specification covering wind loading, safety glazing and hardware in order to provide a genuine 10-year product warranty. The Door and Window frame prices include the complete installation as well and can be forwarded as an indicative offer. The final price is normally established after a survey of the apertures and the fabric of the building. It is a fact that every property and every country has their own installation peculiarities.

For example: When you mention to a German installer that the frames are fitted from the outside and pushed against the internal plaster line (UK method) he thinks you are crazy whilst a British installer cannot comprehend installing a uPVC window frame with a stapler (US method). Installing window and door frames all over the world requires knowledge of building details, practical experience and common sense. Retail surveyors are expected to highlight risk areas and check the actual suitability of the ordered/quoted frame types and styles. In many cases, requirements and regulations have changed over the years leading to a change in fenestration. For example: Window cleaning could be a new customer requirement and the existing frame type may not be suitable or the requested convenience additions like fly screens, louvre shutters and built-in blinds, which may impose new, unexpected challenges.

In the new build market, it is naturally assumed that the fabricator can produce ‘finished’ frames from the drawing sizes and/or frame schedule. But as a word of caution, I still would check the opening sizes prior to the commencement of manufacture regardless of any assurances. Aperture sizes can vary from floor to floor and from apartment to apartment. (Note: uPVC framing started its success story in the replacement market, this is why one-offs or individually sized frames can be fabricated cost-effectively without sacrificing manufacturing efficiencies.)

In the replacement retail market, a thorough and accurate survey is absolutely paramount to establish the replacement frame sizes. The survey will require occasionally the removal of wooden trims, claddings, tiles and render to establish the correct frame size for manufacture. Checking the surrounding aperture for defects i.e. crumbling brickwork, missing lintel, wiring through existing frames etc. and their rectification needs to be raised and agreed upon at the survey stage. Removing frames that are keyed-in and/or frames that seemingly support the whole building structure will necessitate additional engineering work that may be outside the scope of the fabricator/installer, requiring the involvement of other specialist trades.

In the new build market, aperture details and frame handling are well defined on the architect’s drawing and after checking the actual aperture sizes on site (my personal recommendation), frame manufacture seems straightforward thereafter.

In the replacement retail market, the surveyor is the sole (and lonely) company representative who confirms the frame types, establishes the manufacturing sizes, confirms the frame handling, defines the installation method and proposes any building repairs/improvements. Every window surveyor is walking daily on the borderline between success and failure. This occupation has earned my deepest respect because of the responsibility, judgment and trust we place on the correct survey information. But unfortunately,

mistakes can happen easily, surfacing weeks or even months later. Personal example: In the UK twenty years ago, I measured for our new kitchen extension two apertures for uPVC tilt & turn windows which were to be fabricated in W.H.Smith’s window division (the company was later known as WHS Halo, Bowater Building Products and VEKA UK). The window division was headed up by my lovely wife, Maja (in India, Maya). Anyway, it was a straight-through opening, like most of the Indian new-build apertures, but I got one of the width dimensions mixed up. Instead of writing down 1248 mm wide, I wrote down 1284 mm and as Maja’s installation manager came to fit the frames, he discovered the problem, one frame was 36 mm too wide!

He instantly rushed back to the factory (He naturally assumed the factory got it wrong!); Maja found my survey sheet to check the sizes and found the wrong dimension (!!!); the remake got instantly re-computed and rushed through the factory; Maja re-ordered the replacement double glazing unit which got made and delivered in record time to our house; the boys in the factory managed to salvage the tilt & turn to gear and as I came home later in the evening both frames were installed, looked good and functioned extremely well, as expected. As I found out, I could not believe my silly mistake hence my ongoing admiration of surveyors who are being daily confronted with new challenges. The utilisation of electronic devices and the assistance of a second (trainee) surveyor can also help to avoid costly mistakes. Taking, three width and three height measurements to establish the tightest spot of the aperture plus measuring the diagonals to determine the ‘squareness’ of the opening is actually a simple surveying routine but suggesting how to make good and which installation materials to use requires in-depth knowledge and experience.

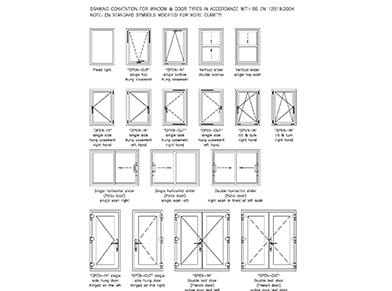

Another common survey downfall is related to the handing and the viewing position of the frames. In Central Europe, all frames are viewed from the inside whilst Great Britain and Ireland view the frames from the outside. In India, you will find both methods adding unnecessary complications to the already complex surveying job. Fortunately, every company can decide for themselves and can adopt their own methods. It is even more concerning when there is an official British Standard BS 7412:2007 and a British/European Standard BS EN 12519:2004 which are in direct contradiction. For example: In BS 7412:2007 the pinnacle is pointing towards the hinges (pointing away from the handle) and in BS EN 12519:2004 is pointing away from the hinges (pointing towards the handle).

Another common survey downfall is related to the handing and the viewing position of the frames. In Central Europe, all frames are viewed from the inside whilst Great Britain and Ireland view the frames from the outside. In India, you will find both methods adding unnecessary complications to the already complex surveying job. Fortunately, every company can decide for themselves and can adopt their own methods. It is even more concerning when there is an official British Standard BS 7412:2007 and a British/European Standard BS EN 12519:2004 which are in direct contradiction. For example: In BS 7412:2007 the pinnacle is pointing towards the hinges (pointing away from the handle) and in BS EN 12519:2004 is pointing away from the hinges (pointing towards the handle).

Adding more information onto survey sheets could be advantageous like drawing the handle position and the hinge position as well as mentioning especially in a separate title box ‘OPEN-OUT’ or ‘OPEN-IN’, just in case!

Clarity of the required information is key to success in any business. Ambiguity, room for interpretations and relying on someone’s memory will always endanger the final outcome and/or result. In the window industry, justifiable pricing, correct frame specification and accurate aperture surveys are contributing largely towards successful window and door installations.