Influence of BIM on Building and Façade Design

The process of BIM supports the creation of intelligent data that can be used throughout the lifecycle of a building or infrastructure project. The benefits of BIM are through connecting teams, workflows, and data across the entire project lifecycle – from design and engineering to construction and operations – to realize better ways of working and better outcomes. BIM allows all players from key building development disciplines – including design, fabrication, manufacturing, and installation to optimize the art of façade design, improve profitability and productivity while adhering to complex engineering principles.

Implementation of BIM Into the Design Process

Architectural façades or architectural envelopes are one of the most exciting and innovative concepts in building design, and historically one of the most challenging. Today, BIM has become central to façade design. One of the key changes that have been brought about by BIM to the façade design module is the BIM parametric design.

By using parametric design methods BIM can enable computational design tools, automate the process, and leverage technologies such as machine learning to develop intelligent solutions. Even though there are different design parameters in a façade design component, it can conduct quick calculations on the different parameters of the façade design model and prioritize projects that are vital. BIM brings the properties of 3D geometric modeling and the capability to analyze performance within it, which has completely revolutionized the façade design process.

Requirements and Differences in BIM and Parametric procedures

BIM parametric design differs from other parametric designs owing to the capability of geometric design within it. Today, parametric BIM modeling is used to deliver increasingly complex designs within project timelines and costs. Façades or roofs of large steel structures are a great example of automating the creating of geometry. Apart from building design, other sectors such as infrastructure construction, itself. The incorporation of computational design and Artificial Intelligence is another major trend that is revolutionizing parametric design.

Bridging Gaps Between Parametric Design and BIM

BIM offers parametric design as one of the methods to create models. In parametric modeling, on the other hand, designers who embed and inject mathematic formulas, constraints, calculations, modular construction have started using parametric methods today.

Latest Advancements and Trends

As parametric design continues to evolve, several latest trends have contributed to further advancement of the technology. This includes integration of real-time data for material and energy optimization, production automation, lifecycle analysis of buildings during the design phase, and control functions to derive a geometric model from a series of input data. While parametric functionality is central to BIM the 3D model represents independent datasets of different objects integrated into it, unlike parametric design where there is total control of the designer exists in the overall form and smaller details related to the project.

To get value out of both approaches, it is best to integrate both elements. While the BIM model can be linked to the performance evaluation based on structured information embedded in the 3D model, the creation of the model itself can rely more on parametric design paradigms where design intent and external information can be used to generate models.

Using parametric design to assist in creating a BIM model will further facilitate the creation of a seamless digital workflow where intelligent data would drive project outcomes over specific tools employed.

Limitations of BIM/Parametric Design

Investments in BIM assure long-term results via smarter and more efficient construction, benefiting not only the businesses practicing but the whole industry. There are considerable cost savings and time in projects including long-term viability. However, some constraints remain that pose a challenge to the adoption of BIM.

BIM is a digital process that requires an investment in technology, processes, and people. Looking at a small aspect of the project alone will not show the return on this investment in a short period. A mindset shift is required for a commitment to technology adoption, manpower modernization, and for building a durable business.

Although, BIM adoption has increased there are still some businesses that have not adopted this approach. This means there might be incompatibilities within the ecosystem creating a barrier to increased adoption of the latest technologies.

BIM to Streamline Complex Façade Designs

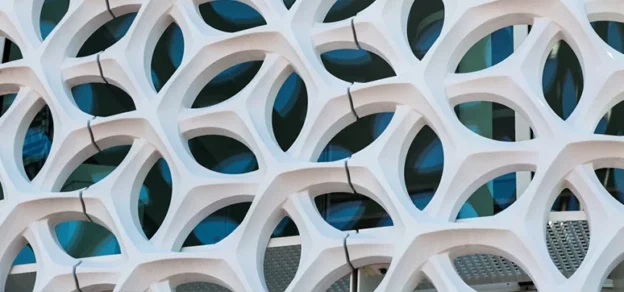

Façade design has significantly evolved with the application of BIM-based processes. As stated above, the primary benefit is the enabling of parametric façade design by changing all elements of the façade into functional algorithms. Based on different parameters, the façade parametric design performs several calculations and statistical analyses for modeling.

In addition, the 3D virtual design in BIM helps in the communication of design data between all project stakeholders.

This is done via data visualization or by generating multi-views of drawings related to the project. This enhances workflows, project efficiencies and helps resolve any discrepancies in a timely manner.

In BIM-based parametric modeling, designs can be automatically updated when parameters of the geometric model are changed. This maintains project accuracy and minimizes errors thereby significantly reducing project and cost overruns.

BIM Brings the Façade Modeling

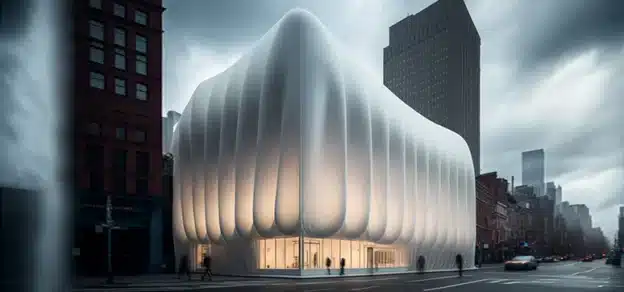

The façade modeling process has significantly benefited from BIM. It has helped to meet the increasing complexity of façade design and fabrication. The switch to 3D models using BIM instead of 2D drawings facilitates accurate capture and transfer of data, besides limiting data loss. In an environment where there are different façade designs for separate projects or within a project, the use of 3D Models can improve building quality and reduce waste.

In addition, BIM creates information about fabrication, transportation, installation, and sequence in a façade panel facilitating its virtual assembly. This helps stakeholders in construction planning as they benefit from an overall view of the project.

The whole process thereby makes it possible to create unconventional building structures through the seamless integration of data, insights, automation, and virtualization.

3D Parametric Modelling and Automation to Help Meet Customer Demands

Adding parametric modeling to your engineering process leads to a significant reduction in time spent incorporating design changes, as a single parameter can cascade geometric updates throughout the model. Unlike direct modeling, designers can create parameters to sketch and dynamically size 3D objects in 3D parametric modeling.

The parametric modeling process allows for intent and relationships to be created between geometric features, which means the shape of your model changes as soon as a dimension value is modified. This refocuses efforts on designing while reducing time spent on manual tasks. With 2D and nonparametric 3D modeling, engineering intent and relationships cannot be built into the model. When design changes are required, significant time is spent manually modifying drawing views and directly editing each geometric feature that must be updated.

The 3D elements and the relationships also help with the manufacturing of the parts. The information required to make the parts becomes an output of the model. In some instances, this information is used to directly drive the CNC and sometimes additive manufacturing machines create the parts.

Technology to Reduce Costs, Reduce Defects and Improve Designs

As seen above, the adoption of 3D design technologies can significantly improve designs, reduce defects and minimize costs. The latest advances in technologies combine data, insights, automation, and enhanced workflows to improve project outcomes considerably. The acceleration of digitalization in the current environment would further strengthen this trend and would facilitate the increased adoption of such technologies. This only bodes well for the architecture and construction industry.