Glass

For thousands of years, Glass was thought of as something to look at. It was valued in making precious objects for decorating purposes. Glass really became useful when it was thought of as something to look through. Ancient art is now a medium of architectural advertisement.

Glass is architectural. Its transparency, masking, fabrication ability, adaptability and specialisation highlight its suitability for structures. To meet the specific construction needs, it can be made transparent, translucent, opaque, diffused or stained by mechanical or chemical means. Processed and cured correctly, it is sound insulating, heat absorbent, heat reflecting, weather resistant, non-abrasive, and incombustible.

Efficient Use of Glass in Façade and Fenestration

It starts with understanding the building requirements and selecting the optimum basic glass and its processing. With the logical and correct selection, glass can be a very useful and friendly material by providing optimum daylight, energy efficiency, sound insulation, comfort and wellness, while being safe from injuries to human beings. An incorrect selection can result in just the opposite by being a source of excessive heat gain or loss, glare, discomfort and risk of injury from glass.

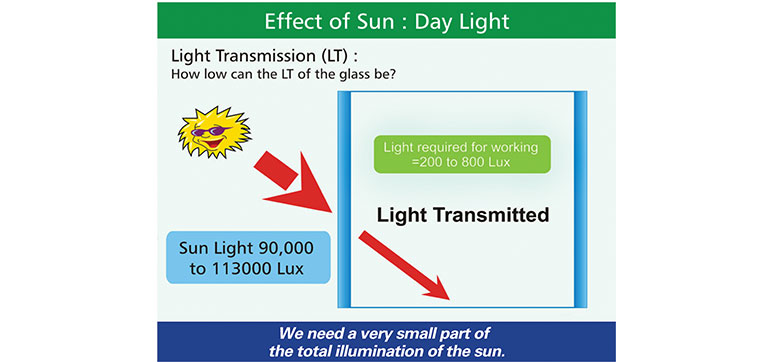

The primary function of glass is to provide daylight and visibility through it or the transparency and one should not lose sight of these primary functions. Visible Light Transmission or VLT is the most important parameter of glass and higher VLT will result in higher daylight but also a higher energy transfer and glare. The designers often consider that a higher VLT means higher transparency and end up with the wrong selection. Transparency is dependent on the colour rendering index, reflectivity and illumination levels inside v/s outside. A glass of VLT as low as 10% is also quite transparent if viewed independently and not in a contrast or simultaneous comparison with a higher VLT glass.

Other than light and energy, the factors like strength, safety, acoustics etc., should be considered to enable us to evaluate the processing needs of the primary or basic glass selected above. It will be useful to bring a method to the selection process which is easily understood by all the stakeholders and steers them to a common approach. The National Building Codes 2016 has introduced a new section 8 of ‘Glass and Glazing’ under Part- 6 ‘Structural Design’. The code covers almost all design aspects of glass and glazing. It explains various types of glasses as well as processes and defines the methodology of selection as well as draws the boundaries of certain limitations.

Right from the initial project evaluation stage, a suitable methodology that incorporates the implications of the use of glass materials and their influence on the performance of the building shall have to be looked into. A typical flowchart outlining such a methodology is given in the figure (Fig. 1).

Design requirements including aesthetic considerations and client-specified requirements such as security and maintenance are to be considered. Effect of design on cost such as initial cost of glazing (specification of glass; glazing method; access for initial glazing; work schedule; protection during construction); effect of glass material on capital/ running cost related to building heating/cooling, lighting and ventilation; and maintenance cost of glazed areas (access for cleaning and re-glazing) should be considered as well.

Considerations for Light and Heat

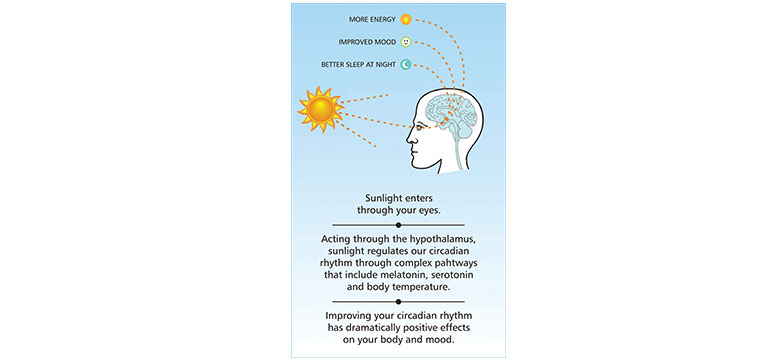

Light: Natural light is important for the health and wellness of human beings. Glass and glazing design must take into consideration the introduction of daylighting into the interior space of the building and manage the external and internal heat loads. External loads include solar heat gains through fenestration, heat losses across the glass surfaces and unwanted air infiltration in the building whereas internal loads include heat released by the electric lighting systems, equipment and people working in the building space.

Proper orientation of a building and due consideration of the size and placement of windows at the design stage can provide the advantage of daylighting.

Daylight Analysis: should be done to find the penetration of natural light on the building floor plan or at the working plane level. This can be done by studying the building orientation, sun path analysis, site shadow analysis and solar exposure analysis etc. A good lighting strategy involves optimising the glazed area, number of Windows, and visual light transmission of glazing. This reduces the dependency on artificial lighting. Using glass with optimum light transmission can go a long way in curtailing the dependence on artificial lighting. The presence of natural light also rids the inmate of the claustrophobic feeling typical in many buildings with limited glazing and outdoor views.

If the light transmission of glass is high, it may also result in ‘glare’ due to exposure to direct sun, or sun rays being reflected from highly reflective surfaces. Analysis helps to understand the ideal VLT requirement for the building. Any glass with energy performance will sacrifice a certain amount of daylight although it will be transparent for vision through it to the outside. The higher the demand for energy performance, the higher will be the compromise on daylight. The selection of glass should therefore start with evaluating the daylight needs and deciding the optimum VLT. This can narrow down the options of selecting the glass that shall give a good performance for the given VLT +/- and considering the cost and aesthetics.

Floor plate geometry plays an important role as the daylight distribution will depend on the depth of the plate from the glazed area. The farthest area from glazing will be the dimmest and the nearest area will be the brightest. The courtyard plan and atrium plan have the great advantage of harnessing maximum daylight from a glazed area not subjected to direct solar radiation by using a glass of higher VLT. Glazing at a higher level will have a deeper penetration of light across the width of the floor plate.

Glare: Glare results from the excessive contrast of illumination or from an excess of illumination in the field of view. When correctly designed, natural lighting should not give a glaring problem. Even when the light transmission of the glazing is as low as 10 percent some 10,000 lux can still be experienced and glare shall almost certainly occur.

Glare can be reduced by some form of mechanical shading, for example, a canopy, an overhanging floor, a balcony or a louvre system. It may also be possible to reorientate the glazing in order to avoid the entry of direct solar radiation. Alternatively, the interior layout can be suitably designed to eliminate glare. Glazing products with light transmission lower than 50 per cent can reduce discomfort glare. These products decrease the sky luminance component but permanently reduce the admission of daylight. Alternatively, shading devices, movable or fixed, may be used.

External shading devices have a great advantage as they address the solar energy transmission before entering into the building to keep the heat out. The internal shading devices will reduce glare but will not be able to prevent the solar energy from coming into the building and then this energy has to be mitigated by airconditioning or ventilation.

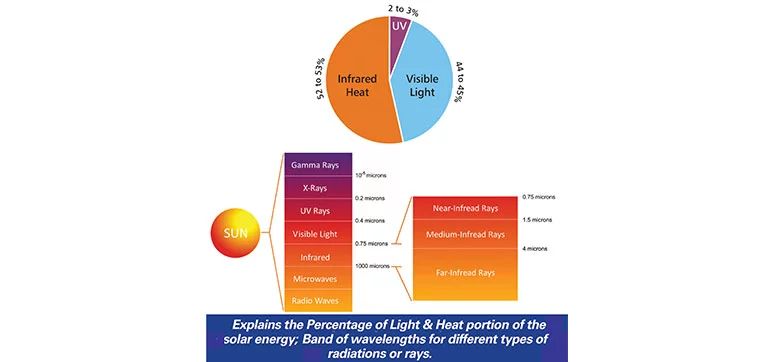

Heat Transfer: It is important to understand the patterns of solar radiation that affect the building. Direct solar incident radiation is the energy transmitted from the sun which lies between the wavelength range of 250 and 2500 nm. Solar radiation is typically made up of 3% ultraviolet light, 42% visible light and 55% infrared light. Infrared radiation is the major heat-carrying radiation followed by visible and ultraviolet rays.

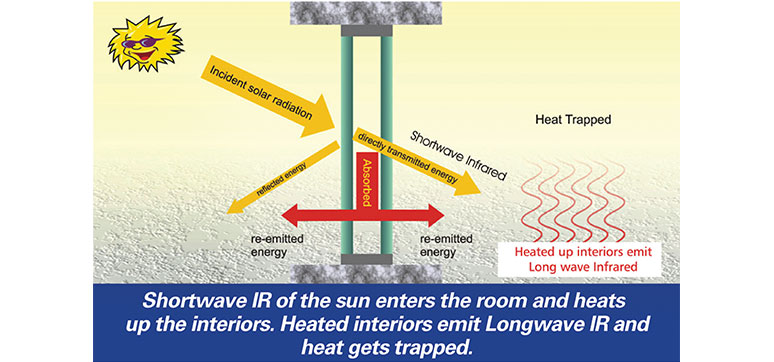

Infrared wavelengths can be further subdivided into a) Shortwave or near-infrared which is more penetrating and will travel with visible light, b) Medium and c) Far or long-wave infrared which gets absorbed by the atmosphere and warms it up. (see Fig. 4).

Analysis helps to understand the sun’s impact over the elevation and from this, the impact on the building can be understood. This helps to understand the peak load values and design can be done considering this. The total solar energy transmitted through the glass from the outside environment is the part of solar radiation which is transmitted directly through the glass and the part which is re-emitted from the glass after being absorbed.

This heat energy which is transmitted through the glass has to be limited in order to achieve thermal comfort for the occupants and also to reduce the energy demands of the building. This is governed by the solar factor or SolarHeat Gain Coefficient (SHGC) of the glass.

SHGC is the ratio of solar heat gain that passes through the fenestration to the total incident solar radiation that falls on it. SHGC is expressed as a number between 0 and 1. The lower the SHGC, the more a product is blocking solar heat gain.

The other part to be looked at is the transfer of heat from the outside to the inside environment through the glass, due to the temperature difference. This is known as thermal transfer and is represented by the U-value which is the rate of heat flow through one square metre of glazing when there is a temperature difference of 1 degree C. The lower the ‘U’ value, the better it is.

Coated glasses can be used as an option for cutting down the heat transmission through the glass since they offer better thermal performance. Solar control glasses have special coatings on them which reduce the amount of solar radiation passing through the glass thereby reducing the amount of heat gain through the glass. Due to these coatings, the amount of light passing through the glass would also be reduced. Care has to be taken while selecting these glasses so that an optimum balance between the light and heat transmittance is achieved.

DGU with both clear glasses and subjected to direct sun will result in penetration of short wave infrared, which in turn will heat up the interiors and cause a heat trap or a greenhouse effect. (see Fig. 5).

Low emissivity (low-E) coatings have a surface emissivity of less than 0.2. The use of such a coating on glass improves the thermal insulation. They are more efficient when used on the cavity surfaces of IGUs. Certain types of low-E glasses such as silver-based are used in double-glazed units only, as the silver oxide coating will get oxidised if used in single-glazed.

Insulating Glass Units (IGU) are a very effective way to reduce transfer through the glazing when used in conjunction with solar control or low-E or reflective-coated glass. These units combine the performance parameters of the individual coated glasses along with the air gap inside the hermetically sealed unit to provide an overall increased reduction of heat transfer.

Increasing the width of the air gap would further improve the thermal insulation of the IGUs. The use of inert gasses like argon and krypton in the air gap would also further improve the level of thermal insulation provided by the IGU.

To maintain thermal comfort and minimise internal cooling/heating loads, the envelope needs to regulate and optimize heat transfer through the roof, walls, windows, doors and other openings.

An integrated building design considers the envelope, the Heating Ventilation and Cooling (HVAC) system and the lighting system as a whole rather than dealing with these independently. Changing the specifications of one system can affect the performance of the other two significantly. The main goal of glass and glazing design should be to provide visual and thermal comfort to the occupants and thereby reducing the electricity cost for lighting and HVAC.

Considerations for Strength and Structural Aspects as Per NBC 2016

Loads: Like any other building material, the glass used in building façades also must adhere to the considerations of strength and serviceability. In general, glass in building façades will be subjected to both in-plane and out-of-plane loading. But the response is usually dominated by the out-of-plane wind loading. Various other loads like dead load, imposed load and seismic design are also to be considered.

Thickness: Based on the type of glass, area, aspect ratio and support conditions, an appropriate thickness can be selected from the detailed tables in NBC 2016 or can be calculated by the empirical formulae for the same. While a design strength factor for normal annealed float glass is taken as 1.0, the factor is 2.5 for tempered glass, 1.6 for heat-strengthened glass, 1.5 for DGU and 0.8 for laminated safety glass.

Deflection: Should be calculated at the centre of the glass panel and is also to be checked for permissible limits. In the case of tempered glass, the design thickness is mostly limited by permissible deflections.

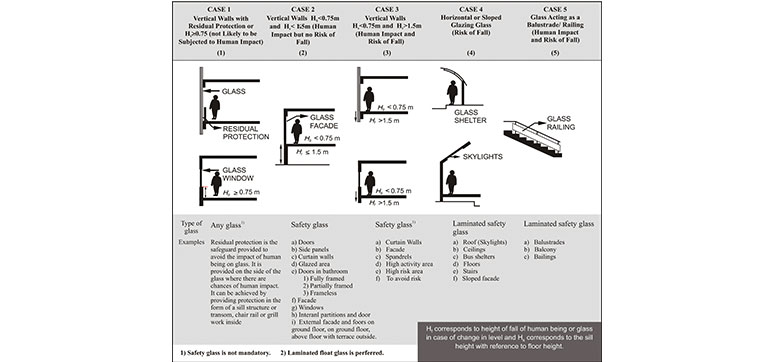

Considerations for Human Safety Critical Locations: The selection of the type of glass is governed by the critical location criteria. Critical locations are parts of a building most likely to be subjected to accidental human impact and safety glass should be used in such critical locations. Safety glass should also be used,

a) Where there is a danger of falling infill glass material(s from overhead glazing.

b) The danger of falling due to a change in floor level.

c) In the case of balustrades, stairs and floors.

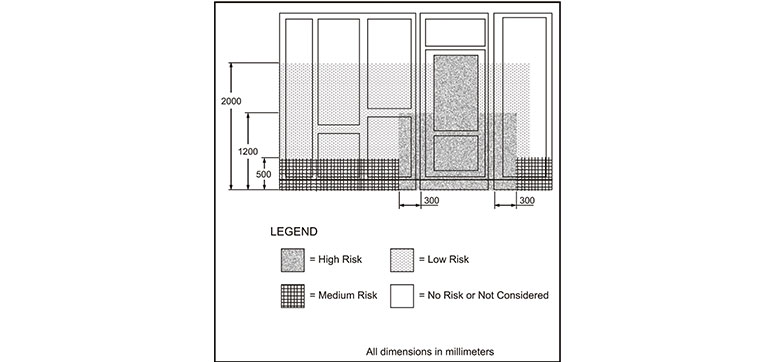

Based on the study, some of the locations in buildings that are found to be more vulnerable to human impact than others are shown in the adjacent figure (Fig. 6) where necessary precautions should be taken.

- In and around doors, low windows

- Door side panels

- Panels have been mistaken for a doorway or opening

- Panels at low levels in walls and partitions

- Bathrooms

- Building associated with special activities, for example, gyms, enclosed swimming pools, etc

- Schools and child care facilities and

- Nursing homes and old age care facilities

Appropriate precautions should be taken to reduce or avoid injuries due to glass breakage by selecting a glass of suitable type, thickness, size and quality as per relevant Indian standards and enhancing a person’s awareness of the presence of glass by making glass visible (manifestation of glass) and minimising manual handling of large pieces of glass during installation.

In the case of external laminated glass façades, openable portions have to be left at regular distances for fire-fighting and smoke exhaust. This portion should be of toughened (tempered) glass and clearly indicated by suitable visible marking.

If an insulating glass unit (IGU) is used in the situations mentioned above, then one of the following shall apply:

a) If IGU is installed in areas subjected to human impact on either side, then both the panes of the unit shall meet the requirements as per IS 2553 (Part) 1

b) In situations where access is restricted to one side of the unit, then only the accessible side should meet the safety requirements of this Section.

Considerations for Acoustic Performance

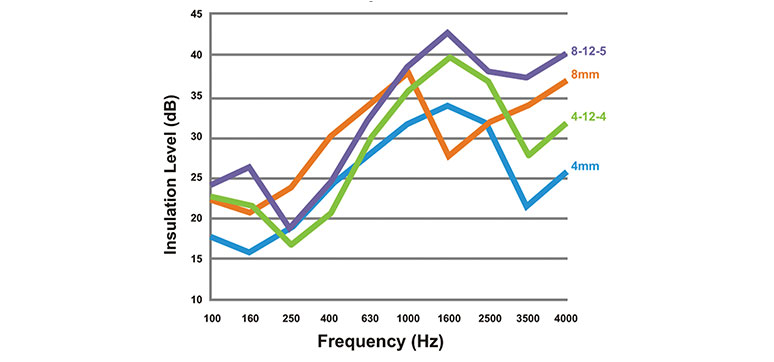

Noise: Unwanted sound is considered as noise when it intrudes in our daily lives. To minimise this intrusion all aspects of the building construction need to be evaluated. However, we will only analyse the acoustic qualities of glass. The first step in this analysis is to determine the source of the unwanted noise. This is a critical step, as the noise source can vary from low-frequency traffic noise to high-frequency aircraft noise. Starting from a single 6mm glass lite with an STC of 31, we can achieve STC ratings of as high as 50 with different combinations of laminated and insulated glasses. Although the increase in absolute numbers seems small, it results in a big difference in performance. An increase from 28 to 38 means 90% of the noise is reduced. A change from 28 to 43 represents a noise reduction of over 95%.

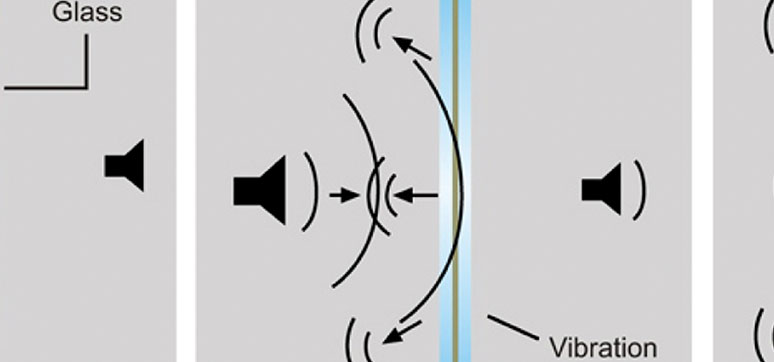

Thicker Glasses: Monolithic glass has a specific critical or coincident frequency at which the speed of incident sound in air matches that of the bending wave of glass. At this critical frequency, glass will vibrate allowing sound waves to penetrate without significant attenuation; the thickness of a single-pane glass enhances the glazing’s sound insulation, for e.g., a 4mm thick glass provides an Rw of 29 dB, which can increase to 35 dB for a thickness of 12mm. However, increasing glass thickness is generally a poor choice for applications such as city structures which are primarily subjected to lower-pitched sounds. This is because increasing glass thickness shifts the critical frequency trough towards lower frequencies which results in weakened protection against low-pitched sound.

Insulating Glass with Different Thickness: Contrary to the common belief, DGU or insulating glass is not effective against sound insulation. To enhance the level of sound insulation provided by double glazing, glasses with sufficiently different thicknesses should be used so that they can minimise its weakness when the overall unit reaches its critical frequency. This therefore produces a coincidence in a broader frequency zone but compared to symmetrical glazing the trough is less intense.

Laminated Glass: The polyvinyl butyral inter-layer (0.38m m to 1.52mm) used in laminated glass provides a dampening effect that reduces vibration by absorbing the sound waves hence reducing sound transmission. Laminated glass has superior sound insulation qualities in the higher frequency range where the noise from sources such as aircraft is a problem.

The PVB film used in laminated glasses has a shear-damping effect that has substantial sound attenuation characteristics. When the outer glass layer is exposed to bending waves, the PVB layer creates a shear strain within itself and the bending of wave energy of glass is transformed to nondirectional heat energy which is barely noticeable. During this phenomenon, the sound waves are absorbed by the PVB layer and not transmitted to the second glass layer. This results in a reduction of the amplitude of vibration and sound transmission. Increasing the inter-layer thickness has a marginal effect on the performance of laminated glass. Acoustically enhanced PVBs are designed to have higher damping characteristics that further reduce the amplitude of the sound waves.

Combination of Insulated and Laminated Glass: Further increases in sound-reduction performance can be achieved by using combinations of insulated and laminated glass. These units offer the dual benefit of greater mass and different frequency resonance of insulated glasses coupled with the damping effects of PVB laminated glasses. Double-glazed units with certain gases also provide sound insulation characteristics.

Areas around Windows: It is important to note that no matter how good the noise insulation qualities of the windows are, there should be no gaps or cracks around the window frame and these are sealed with soft sealing materials.

Other Considerations

Fire Safety: Fire-rated glass has to be used indoors and partitions of fire escape routes and refuge areas. There are three broad classifications of fire-rated glass to be used depending upon the estimated evacuation time for the occupants, size of the glass and NBC Compliance requirements:

- Integrity (E): Glass that stops the spread of fire and smoke from the fireside to the non-fire side and stays in place for a defined time or rating of 30, 60, 90, or 120 minutes or more.

- Integrity and Radiation Control (EW): In addition to the above, it also controls the radiation to < 15KW at 1m.

- Integrity and Insulation (EI): In addition to (E), it also gives very high heat insulation and limits the temperature on non-fire side glass to 180 at any point and an average of 140 max.

- UV Control: UV light, though 3% of solar radiation, is responsible for fading of the upholstery and causes discomfort. PVB in laminated safety glass absorbs 99% of the incident UV giving more comfort and longer life to upholstery and other interior objects. This is of particular importance to Hotels and Premium Houses.

Thermal Breakage: This can happen only in annealed glass due to temperature differences at the edge and centre of the glass with higher absorption. Tempered and Heat Strengthened glasses are safe from Thermal Breakages.

Spontaneous Breakage: This can happen in tempered glass due to nickel sulphide particles. It can happen even after installation and even after a gap of months to years. Heat soaking of tempered glass is recommended to reduce such risks but involves additional costs. The complete phenomenon has been published in the WFM issue of July-August 2015.

Conclusion

Glass is a wonderful material for the future. Its appropriate selection and application combined with understanding the building requirements can be a very rewarding exercise resulting in a delightful experience for the users of the building.