As urbanisation in Indian cities is continuously growing, the construction industry has also boomed, employing new techniques and materials to meet the ever-growing demand of high rise buildings. In order to protect these buildings from wind, rain, sunlight, heat and cold, façades are being increasingly used and have become an integral part of the building. Fig.1 shows some of the buildings with façades.

However, in the quest of making such buildings look more elegant along with energy and cost-efficient, the construction industries are using different combustible materials in the façade, which is of great concern as far as fire safety is concerned. The magnitude of fire risk involved in these façades has already been proven by many accidents occurred across the globe. Case histories have shown that these combustible cladding’s promote the fire spread on façade and engulfs the whole building within a few hours as shown in Fig. 2.

Fig. 2: Façade Fire Accidents Occurred Worldwide [Source: News articles]

Fig. 2: Façade Fire Accidents Occurred Worldwide [Source: News articles]

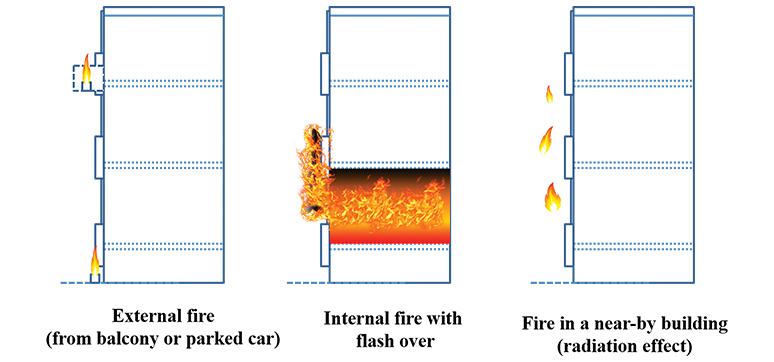

Fig. 3 highlights the common scenarios behind these façade fires. Mostly these scenarios include external fires in the balcony or internal fires near to windows. A low-intensity fire near to these areas can lead to a major fire accident as what happened in the Grenfell tower accident in the UK (2017) where the initial fire source is supposed to be a fridge on the 4th floor near to the window. Some of the flames from the fridge reached combustible exterior cladding from the window openings and in very less time, the fire reached the top floors via the cladding and in 3-4 hours, the whole building was on fire.

Fig. 3: Façade Fire Scenarios

Fig. 3: Façade Fire Scenarios

In other cases, the intensity of internal fires (which are away from the windows or balcony) may also increase, leading to flashover conditions inside the room. These flashover fires easily come out of the building via windows and doors and start impinging on external façade. If this external façade is also combustible then fire starts spreading vertically and enters other floors of the building, thereby worsening the situation even more. The combustible façade may also get ignited because of a fire in a nearby building due to radiation effects.

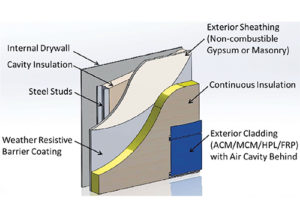

Designed by advanced engineering methods and techniques, these external façade systems have become complex and constitute an important percentage of the overall cost of the building. Generally, they are an assembly of three components from different manufacturers and suppliers – exterior cladding with an air cavity behind, continuous insulation (CI) and water/weather resistive barriers (WRB) as shown in Fig. 4.

The Three Components Of External Fire Safety Facade Systems are as follows :

This air cavity serves the purpose of draining down the rainwater and also causing upward airflow within the cavity in hot weather, thereby removing moisture on the façade and keeping them ventilated. In the event of a fire, this internal cavity forms a chimney effect along with a combustible façade and hence causes rapid vertical fire propagation to other floors.

2. Continuous Insulation (CI): The second component of the assembly is a layer of insulation, which is installed on the exterior structure of the building to increase R-value of the external wall of saving energy by insulation. Mostly used CI include XPS (extruded polystyrene), PIR (polyisocyanurate), phenolic foams, mineral wool, etc. Their thickness depends upon the climate zone and R-value desired. Combustible insulation along with combustible exterior cladding can worsen the situation in case of fire.

3. Weather/Water-Resistive Barrier (WRB): It forms the third component of the assembly and is installed over the exterior sheathing and under the CI. It is used to prevent moisture damage to the building and also helps to maintain the comfort level inside the buildings by regulating relative humidity. Generally, used WRBs are either fluid-applied membranes or building wraps.

Two important parameters that define the performance of fire-safe façade materials is their combustibility and smoke production. If façade material are combustible, it will contribute to the fire spread to other parts of the building, which may lead to completely engulfing the whole building. Secondly, façade materials may also produce toxic smoke, which causes more deaths than the fire itself as it spreads quickly in no time worsening the situation even more. The toxic content of the smoke will depend upon the material.

Current Research (Investigate & Prevent) :

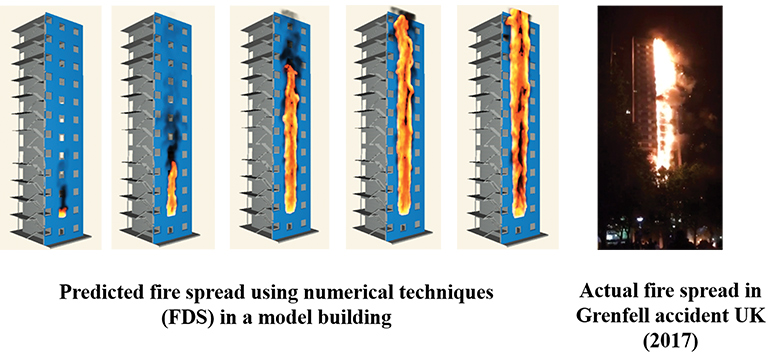

Fig. 5: Effectiveness of Numerical Techniques (FDS) to Assess the Façade Fires [Source: Ankit Sharma, Kirti Bhushan Mishra – Modelling of High-Rise Façade Fires, 09/2019, Proceedings of 14th International Conference & Exhibition – FIRE INDIA 2019].

Fig. 5: Effectiveness of Numerical Techniques (FDS) to Assess the Façade Fires [Source: Ankit Sharma, Kirti Bhushan Mishra – Modelling of High-Rise Façade Fires, 09/2019, Proceedings of 14th International Conference & Exhibition – FIRE INDIA 2019].

Due to the presence of a variety of flammable items in a building, fire scenarios can be complex for these exterior cladding. Such fires are impossible to reconstruct physically and are only possible to study by using computational techniques like Fire Dynamics Simulator (FDS). The only alternative available today for assessing such façade fire risk in high-rise buildings appropriately is to use modelling driven performance based fire safety design.

Fig. 5 shows the comparison of fire spread in Grenfell tower and in a model building with LDPE (Low- Density Polyethylene) cladding using FDS [Reference: Ankit Sharma, Kirti Bhushan Mishra – Modelling of High-Rise Façade Fires, 09/2019, Proceedings of 14th International Conference & Exhibition – FIRE INDIA 2019].

Flashover scenario has been considered on the second floor of the model building where the flame comes out of the building and start directly impinging on the exterior cladding. It can be seen that during the initial stages vertical fire spread is more prominent compared to a horizontal one as was also observed in the Grenfell tower accident.

Other methods to limit the fire spread to exterior parts of the building is to solely use noncombustible or fire safety materials in the façade assembly. Avoiding any combustible items in balconies or near to windows and using sprinklers near to these high-risk areas will also suppress the fire in the initial stages.

Further, the actual fire behaviour of a building façade does not only depend on the fire performance of its components rather it is dependent on the overall system’s performance. The combustibility of all these components can influence the fire performance of the whole assembly. Sometimes, the cladding may be less combustible while the CI may be highly combustible.

Hence, it becomes important to perform assembly testing to study their actual behaviour. In the EU, the fire testing and classification standards for construction products follow European Standard EN 13501-1 that compares ignitability, flame spread, heat release, smoke production and flaming droplets/ particles, etc. It classifies material in seven classification levels, from A1 to F based on four fundamental reactions to fire tests which are EN ISO 1182 (Non-combustibility test), EN ISO 1716 (Gross calorific potential test), EN 13823 (SBI Single Burning item test) and EN ISO 11925-2 (Ignitability test).

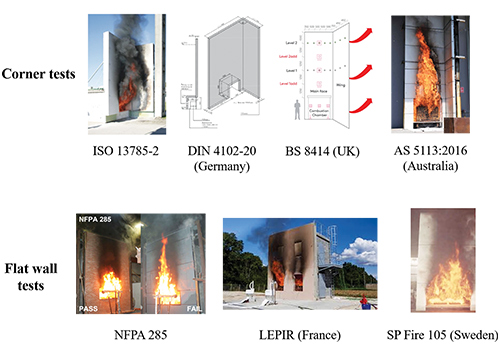

Large-scale tests for external cladding systems vary depending upon the country as shown in Fig. 6. A common feature in all these tests is that a post flashover room fire scenario is considered where the fire source is placed near to the window and flames come out through the opening and start impinging on the external façade.

Either these tests are corner tests where a sidewall is added to give corner effect to fire plume as in ISO 13785-2, DIN 4102-20 (Germany), BS 8414-1:2002 (UK), AS 5113:2016 (Australia) or flat wall tests as in NFPA 285, LEPIR (France), SP Fire 105 (Sweden). Fire assessment of the systems in these tests is done based on different criteria mainly flame spread and temperature threshold. It has been observed in different research studies that the height and width of openings also have a greater influence on the height of window ejected façade flames and hence flame spread.

In order to achieve the highest level of fire safety, both fire protection engineers and architects must work together using prescriptive and performance-based design approach. Especially in high-rise buildings, façade and fenestration design must go together as both in conjunction are responsible for fire spread to other parts of the building via exterior combustible cladding and insulation.

-The views and opinions expressed in this article are those of the author and are not linked to any agency, organisation, employer or company.