When you consider that asphyxiation from smoke and noxious gases accounts for more than 40% of fatalities (according to the DCLG) and that most deaths happen to people who were not in the room where the fire originated, it is easy to see why firestop is critical to prevent the passage of flames and noxious gases from one floor to the next.

The risk of fire spread through articulated elements of the façade or vertically around the façade via the mechanism of flame leap poses new concerns for the newest class of super high-rise structures.

The concerns revolve around the issues of fire department response capabilities, reliability of sprinkler systems and associated water supplies and the characteristics of the building and building occupants. More importantly, as architects develop a new and leading-edge creative curtain wall designs, it becomes more critical to consider the risk factors that can impact the building’s overall level of fire safety.

The risk factors that may influence issues of curtain wall fire safety design should be considered and it should be discussed that what building system and features can factor into an analysis to validate a specific curtain wall design detail.

Curtain walls are a relative complex combination of components that include aluminium frames, vision glass, metal back pans, insulation, gaskets, and anchors or connectors of steel or aluminium. Given a fully developed fire exposure in a room or space bordered by a building’s curtain wall system, it can be expected that vision glass failure will occur within minutes.

Once the failure occurs, the flames are extending to the exterior, the various curtain wall components and the perimeter fire system is then subjected to thermal forces and degradation that can result in fire spread to the floor above.

FireStopping Is Part Of Effective Compartmentation

It is the building of fire, smoke, and other resistancerated assemblies into “boxes” in buildings. These boxes are built to keep the fire from spreading from the room of origin to other parts of a building.

Compartments are formed when the area or fire walls separate one space from another, allowing the collapse of one side without the other sides being structurally affected. They are also formed when resistance-rated walls are constructed in corridors, when resistance-rated floors are built for floor-to- floor protection, and when spacing between buildings is added to protect against fire spreading from building to building.

Fires in high-rise buildings generate large quantities of smoke that tend to spread vertically throughout the building, even if the fire is contained to only one room. Smoke travels at up to 130 metres every minute and whilst most people can easily move at this rate in normal circumstances, the majority of survivors of fires stated that smoke restricted their ability to see to no more than 4 metres.

When the linear gap at the perimeter edge between the floor and curtain wall is not properly sealed, flames and smoke will spread vertically to higher floors. Addressing these linear gaps by properly installing firestops, maintains the floors fire compartmentation of the building. This delay vertical smoke-spread and reduces the risk of smokerelated deaths in the upper floors of the building.

Fire Safe Solution

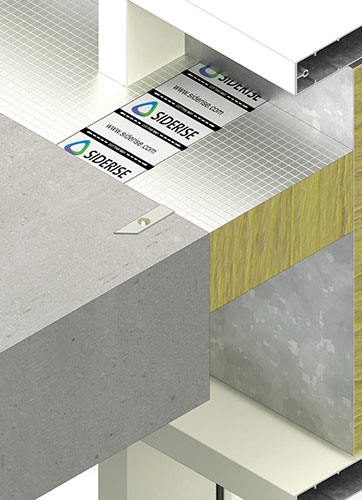

The perimeter barrier firestop seal the linear gap between the edge of the compartment floor slab and external curtain wall. Due to project design and site tolerances, this linear gap can be variable, so the firestop system used needs to have a degree of ‘dynamic’ movement capability – compression and recovery – in order to accommodate serviceability movement.

What is critical – is the firestop system must do this in combination with the primary functional requirement, which is to maintain continuity of fire resistance between the compartment floor and the external wall. The installed firestop system needs to match the same period of fire resistance as the compartment floor.

All Firestop Systems Need to be Tested to Two Criteria – integrity and insulation (EI).

• Integrity (E) refers to the ability of the system to prevent the passage of flame, smoke and combustible gases either through, around the material or through joints in an assembly; while Insulation (I) refers to a measure of the increase in conducted heat transferred from the exposed to unexposed surfaces of 180°C rise above ambient.

These two criteria are critical in the development of curtain wall perimeter firestop products. The most effective products combine a number of material features – density, thickness, resin content, fibre structure and controlled compression, which together determine the resistance properties.

When looking at the integrity (E) criteria, the material chosen must be impervious to the transfer of flame and gases, easy to install with the minimal site management and accommodate all real-world requirements at interfaces, joints and details.

In order to meet the fire and smoke stop requirements in all external façade applications, the Certifire approved SIDERISE CW-FS perimeter barrier and firestop systems offer an un-rivalled combination of fully-qualified performance, practical installation and service benefits.

The principal function of the Siderise CW system is to maintain continuity of fire resistance by sealing the linear gap between the compartment floors or walls and external curtain walls both horizontally and vertically.

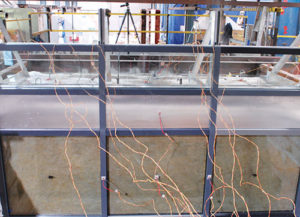

Siderise’s perimeter barriers and firestops for curtain walling uses a patented method of manufacture that provides a resilient lateral compression. This facilitates installation, ensures the requisite tight fit and enhances fire integrity (E).

Throughout the range, the materials comprise a one-piece product with a pre-compressed non-combustible stonewool core. The products also have integral aluminium foil facings to provide an overall Class A1 rating and excellent resistance to the passage of smoke.

SIDERISE CW-FS perimeter barrier and firestop systems also offer an unrivalled combination of independent third-party Certifire-approved performance data for both horizontal and vertical applications, Certifire Certificate No. CF563 refers.

The systems can offer tested fire rating options ranging from 30 minutes to five hours and can accommodate void widths up to 1200mm. In addition to providing an effective seal against the passage of smoke and fire, the products will also function as an effective acoustic barrier and plenum lining.

Sealing The Voids

At the $135 million Al Fattan Crystal Towers, recently completed at the Dubai Marina in the UAE, fire safety was paramount in a development that includes hotel rooms, suites and residential apartments.

With both vertical and horizontal fire compartmentation requirements, the specification of SIDERISE CW-FS 120 firestops provided the contractor Cladtech with a one-stop-shop solution that could maintain a fire and smoke seal in one product and could successfully fill linear gaps at the podium levels in excess of 300mm.

For the two towers, Cladtech installed 12,000 LM of SIDERISE CW-FS 120 firestops including horizontal (floor slab) and vertical compartmentation. With the timeline of the project critical, the use of this dry fix system enabled the work to be completed quickly and efficiently, ready for handover to subcontractors.

Throughout the application, SIDERISE provided comprehensive support, including drawing assistance, liaison with the authorities for approval, installation training and periodic site inspection and assistance. Whilst specifying the correct product is vital, the quality of installation is equally as important.

Contractors installing life-saving measures such as perimeter barriers and firestops must have adequate training on the particular manufacturer’s products and be qualified to install them in the first place. When it comes to saving lives and protecting businesses and property, a well-designed and installed system can make a difference.

We believe in effective compartmentation as a major measure to protect life safety in buildings. The properly designed, installed, inspected, and maintained, effective compartmentation components should provide reliable protection.

Top questions to ask when purchasing firestop systems that have insulation as a component:

• What tested and listed systems are the insulation tested in?

• Is the insulation part of a tested and listed system?

• Is the insulation specified by name in that tested and listed system?

• Show me that system!

• For more information about products, materials, systems and selection, and testing, visit the certification database.

Firestopping is a matter of matching the tested and listed system with conditions as they exist in the field exactly. There are no ‘construction tolerances’, ‘make it fit’ or other variations allowed unless specified in the tested and listed system. Once a contractor understands that philosophy, and makes it part of the corporate culture, from office to field, then successful fire-stopping projects can take place.