Fire accidents in the buildings are one of the major concerns for the builders, developers, architects and government authorities in the Middle East. Now, building regulations have seen advancements in recent years in the region. Recent developments like the Dubai Expo 2020 is imposing strong regulations for the façade fire safety material and equipment market.

The new UAE Civil Defence Codes have revolutionised the façade industry and also offer a higher standard of regulation as compared to the previous regulations. Many fire incidents have been witnessed in the Middle East region in the last few years that have taken many human lives and caused economic losses. In order to minimise these losses, the fire safety codes are getting stringent. To understand this critical aspect of façade fires, we interviewed many key players in the industry and gathered their thoughts on this important topic. This edition’s cover story deliberates their views on the subject – the Façade Fire Safety in buildings in the Middle East.

The Impacts Of Facade Design On Fire Safety Of Buildings

Mayank Sharma, Technical Specification Manager, Siderise Insulation observes that in recent decades, with the desire for taller structures and with a strive for improved energy efficiency by adding exterior insulation, we sometimes encounter potential conflicts with fire and life safety codes.

With the popularity of building certification programmes to net-zero energy building initiatives, to the active building enclosure movement, the expectations continue to increase for building performance, facility life, and occupant health and safety. Because, two of the most critical aspects of high-performance buildings are air/water tightness and the enclosure’s thermal performance, the necessity of using more insulation, and high-quality air/water barrier and flashing materials will continue to increase as the industry trends toward highly energy-efficient building envelopes. When it was realised that combustible material was being used in large quantities in exposed areas, the code officials and manufacturers got together and established codes and policies to protect life safety.

Sandeep Thakur, Priedemann, Dubai, United Arab Emirates notices that the reason for many fire-related mishaps around the world is a combination of many aspects like improper use of materials and designs, lack of awareness, etc. He adds, that since the question is more focused on the design matter, the suggested approach will be as follows:

• Take reference to the code of practice established in the specific market or similar markets (in the absence of such code). These codes are established under microscopic studies of multiple fire mishap cases, individual past experiences and in line with the specific social awareness and behaviours in that particular market.

• Make use of recognised products and technologies. These products and technologies are usually developed with extensive research and case studies. Complying with its instructions is an absolute necessity.

• Use common sense and rationales to assess the risk of fire initiation and propagation to apply above said preventive measures.

• Include measures within the design to save lives and properties, in case of such mishaps.

• Where uncertainties exist, avail expert knowledge and refer to relevant test requirements, as the nature of complexity and material may vary from project to project.

According to Peter Stephenson, Business Development Manager, Warringtonfire, the performance of a façade system in the event of a fire can be the result of many factors, including the selection of individual components/materials making up the overall system, location of the fire origin (internal or external fire), provision and location of fire barriers and associated perimeter edge fire stopping systems. The correct testing, certification of installation and build-up of a system are very important and poor workmanship can negate a system’s ability to perform as designed to reduce the effects of fire.

Each individual component of the façade system should be tested to ensure its reaction to fire, etc. and the whole façade system should also undergo a full fire test, such as BS 8414 or NFPA 285. Fire safety, in the context of the façade, starts at the design stage. This must be a collaborative and coordinated process, along with the other technical disciplines and the architect should ensure that the design aesthetic intent is met, with the required technical performance.

The conversation should start as early as possible, whilst opportunities remain broad. As the design is refined in the transition from concept to IFC, those opportunities become narrower to nil, so giving the correct design direction at an early stage is essential. This is the case for new designs on new buildings – existing buildings are a different matter, of course, says Andy Dean, Head of Façades, The Middle East, WSP.

Parameters Defining The Performance Of Facade Materials During A Fire

According to Sharma, as codes and terminology have become more technical and complex, the lack of understanding of the basics on façade performance continues to feed an age-old problem. To start with, let’s understand the difference between ‘reaction to fire’ and ‘fire resistance’.

Generally, materials used in façades are burnable, notes Thakur. “While selecting the material for the projects, the criteria we would like to emphasise is, what is its behaviour in terms of fire propagation, smoke development, nature of droplets and so on. At times, there are elements of uncertainty in the exposure of the selected material. In those cases, we advise on special testing sequences”.

Stephenson says a façade system should meet the requirements of local fire code standards. This will generally include a full system fire test. The performance of the façade components should be assessed against resistance to fire tests, reaction to fire tests and fire propagation. Dean explains that, just like any other part of the building, the parameters fall into the well-established categories of Reaction to Fire (RTF) and Fire Resistance (FR). Understanding what these are and how they affect a façade is critical. In brief, RTF is how and if materials burn. FR is the compartmentation of a fire.

Dean adds, these categories themselves are fundamentally passive processes, as opposed to active processes. That is, there are no mechanical moving parts, or fluid reservoirs or the like as is the case with active systems such as sprinklers or other suppression systems. Whilst there are some active systems for façades, the core of the performance should aim to be passive. Using a flammable material for a façade, which needs an additional active system to extinguish it in the case of a fire is costly and adds risk – what if the active system does not work?

Difference between Fire Resistance and Reaction to Fire

The regulation requires the fire performance of construction materials to be considered, and in simplistic terms, the building components must not contribute to the ignition and spread of a fire, whilst the fabric elements must be resistant to fire in terms of their ability to provide the necessary structural and (fire) separation functions. Designs to achieve these requirements typically call upon two types of fire test data – reaction to fire and fire resistance.

The former describes the combustibility characteristic of building materials, the latter describes the period for which particular construction can resist exposure to a specified fire load, whilst maintaining its form and function. A major difference between buildings built today and those built as recently as 50 years ago is the level of thermal insulation. The thermal benefits of insulation are well understood, however, consideration must be given to the effect of its presence – both in terms of the reaction to fire characteristics and the impact of high fabric insulation values of structures when involved in a fire. Reaction to fire classification is now largely based upon the European Standard EN 13501-1 giving European classes, or ‘Euroclasses’ and for most building materials, it is determined from a combination of four tests.

There are seven levels of classification from the A1 (non-combustible), A2 (limited combustibility), B, C, D, E and F. A1 being the highest performance and F being the lowest. From reaction to fire classification, the critical thing to note is that the nature of the testing changes from classes A1 and A2, where the focus is to show that a product is non-combustible, whereas for classes B and below the focus is on the degree of combustibility.

Where reaction to fire looks at a material’s individual property, fire resistance classification relates to how building elements, including specifically purposed fire protection products, and their installation, can be expected to behave in the event of a fire. Fire protection classifications are commonly reported in terms of a period of fire resistance, for example, 30 minutes.

The classifications relate to integrity (E), thermal insulation (I) and load-bearing capacity (R) either singly or in combination. In simple terms, where a fire occurs, stopping it spreading (E), restricting the temperature rise on the opposing side of the element (I), and maintaining the element load bearing capacity (R). The test methods are defined in British Standards (BS) which determine the conditions of the test as well as the preparation of the test element.

Mayank Sharma, Technical Specification Manager, Siderise Insulation

Features Of Facades Which Prevent The Spread Of Fire

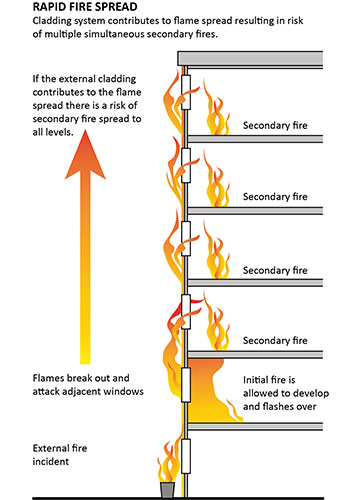

Sharma highlights typical scenarios of fire spread over façades:

• The spread of the external fire onto combustible façade by radiation from the neighbouring, separate building,

• The spread of the external fire onto combustible façade from the source of fire located next to the façade, with the consequence of radiation or direct exposure to fire (litter on the balcony, parked cars, etc.),

• An internal fire that has started in a space inside a building spreads through openings in the façade (windows, doors, etc.) onto higher or lower floors.

• When flames (whether from an internal or external source) spread onto the external layer of the façade, further spread across the façade will depend on façade system properties where the most important factors are as follows:

• Reaction to fire properties of the materials on a façade, influence the speed of fire spread on the envelope of a building. The mechanism of fire spread through openings on an ETICS façade with combustible insulation.

• The existence of cavities in a façade (which are part of façade systems, e.g. ventilated ones, or the ones formed by parts of the façade delaminating during a fire). If fire enters a cavity, due to the chimney (stack) effect, it can be extended five to ten times from its initial length, regardless of the properties of the material facing the ventilated layer. If fire barriers are not used, the described effect will cause fast vertical fire spread, which can be “hidden” below the cladding on the façade.

• Openings on a façade (windows, doors, etc.) that enables the fire to return to and enter the indoor space of a building, when it can further spread from floor to floor according to the abovedescribed mechanism.

Thakur believes that before discussing “fire spread” or fire propagation, we should tackle the fire initiation possibilities. Often we see the origin of fire at the garbage collection close to the building or collection of cigarette butts at the odd corners, etc. Different stakeholders of project need to put conscious efforts to have it designed to avoid such situations. Usually, the direction of façade panel fixation on the building is favourable to fire initiation and fire spread.

This is because the thinner side of the panels is directly exposed to origin of fire and its flame. So, material used for façade should not be easily combustible. Also, the main reason for fire propagation is due to the “chimney effect” behind the façade panels. Once the fire is initiated, it utilises the oxygen in the space behind the façade. Then the fire seeks more and more oxygen. In its magnitude, fire rushes through the cavity of façade quickly from the bottom of the building towards the top. Such propagation can be stopped by providing barriers to cut the fresh oxygen present in the cavity.

This is where compartmentalisation of the cavity helps. Another measure to contain the fire spread is to design the floor level spandrel in such a way that, even if the infill of the façade is absent, the fire flame from lower level should not reach the floors above.

Stephenson points out that the façade system should be designed by a competent design specialist with correctly specified and detailed components that have satisfied and passed appropriate fire tests. The inclusion of intumescent fire barriers and non-combustible products forming part of the system build-up will reduce the severity of losses in the event of a fire. The inspection regime of the finished system on-site and during installation is an important aspect, which can often be overlooked to ensure that the installation meets all of the design and test criteria.

Dean suggests that expanding on the RTF and FR performance categories, and taking RTF first, we need to make sure that the façade materials are not easily ignitable – an irresponsibly discarded cigarette, for example, should not be able to start a façade fire. Surface spread of flame would be our next concern – if a façade is next to a fire, maybe it is burned, but the materials that the façade is built from should not then spread that flame outside the zone of the original fire.

He added, those that have called for ‘façades to be non-combustible’, do not understand façades, neither understand fire. ‘Non-combustibility’ has a very strict definition in the fire industry and only materials like glass, stone, solid metal and the likes can achieve it. However, we need gaskets, sealants, thermal breaks and other plastic/polymer materials for the façades to make them work properly. Although the performance of these small components should have some understood limits, if all other aspects of the façade are controlled, then the small, necessary combustible components have an equally limited effect.

Turning to FR (fire resistance) or compartmentation, the fire safety strategy created by the fire consultant informs the façade consultant where the fire stopping should be and if a façade itself needs to be fire-resistance rated. Common examples are horizontal fire stops between slab edge and the façade; the spandrel panel itself (so that the spandrel panel doesn’t deteriorate in a fire), vertical fire stopping between party walls and the façade; and car park entrance glazing. The requirement for other façades to be FR rated is less common, but we’ll come on to that in the next question. Dean believes that it is important that all of these aspects work together to collectively create a system that is low-risk.

Importance Of Fire Resistance Rated Glass

Fire-rated glass system is needed only if compartmentalisation is needed as a part of the fire strategy of a building, we don’t have to design the entire façade with it. There is no substitute for a fire-rated glass yet. When you need to see through function, and you need it to be fire-rated, than glass is the only material that fits the description, says Mayank.

Thakur believes that the importance of fire-rated glass depends on the context of its application. All kinds of façade on the building should discourage fire propagation and smoke development, but it does not require to be fire rated. There are regulations in place to have fire-rated façades if the adjacent building is less than a certain distance. There is a necessity of fire-rated façade or partition if there are refuge areas separated into other areas. In those cases, the façade shall be fire rated. There is no substitution to fire-rated façade systems and glass together for such cases.

Fire-rated glazing plays an important role within the built environment, particularly where clear vision and architectural aesthetics play an important part in a design. The duration of fire rating required, will impact on the cost of this type of design solution as will the area to be covered, says Stephenson. For large areas, a fire shutter or fire curtain could be used as an alternative solution that can be deployed in the vent of a fire to close an opening and provide the required fire separation as per the code requirements.

According to Dean, fire resistance-rated glass (or more accurately ‘glazing system’ because glass cannot exist without the system, it is held in) is essential if the fire safety strategy requires that the particular area of façade needs to provide that level of performance. However, the need for fire resistance in a façade is not common in modern cities. Notwithstanding that certain elements of the façade system need to provide a fire stopping function – the perimeter firestop for example – the need for the façade itself to be fire-resistance rated is usually only present if buildings are spaced closely together – the premise is that if the fire is contained, it can’t spread to the adjacent building.

There are other particular examples, such as if a fire escape route next to a façade needs to be protected, or if there is a clear fire potential such as a car park or plant room. There may also be other important spaces with a façade that need protecting such as document storage rooms or critical function spaces. Dean adds that the cost fire-rated glazing is generally higher than non-rated glazing. “However, compared to the damage that an uncontrolled fire would do, it is good value”. There are less expensive options, such as block work, but then they tend to be less elegant and do not offer visibility that may also be an important requirement.

Role Of Fire Stop In Fire Safety

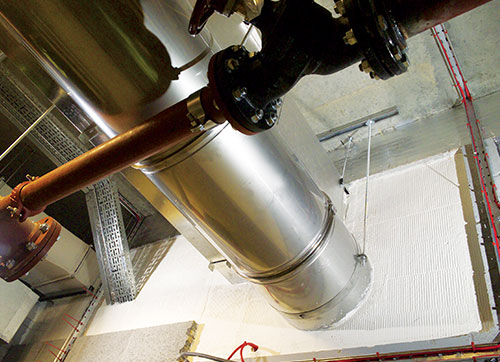

Sharma notes that a fire stop is a sublime fire protection measure that seals openings and joints in a fire-rated wall, minimising fire escalation. They hinder the transference of smoke and fire through cracks and crevices in walls and floor assembly. These are available in varied forms and materials like cementitious mortar, silicone, rubber, etc. Fire stops materials and systems are used to ensure the fire is contained within the compartment created as part of the fire resistance strategy. Any areas like through penetrations and parts of cladding system create gaps and openings in the compartments designed to contain the fire.

According to Stephenson, fire-stopping plays an important factor in the overall fire & life safety provisions of a building. Fire stops can be used to effectively limit the spread of fire and smoke between areas/rooms by effectively sealing openings around openings for penetrations such as pipes, cables, and ducts. Systems can be provided to close openings between walls and floor slabs and also at the perimeter edges between floor slabs and façades.

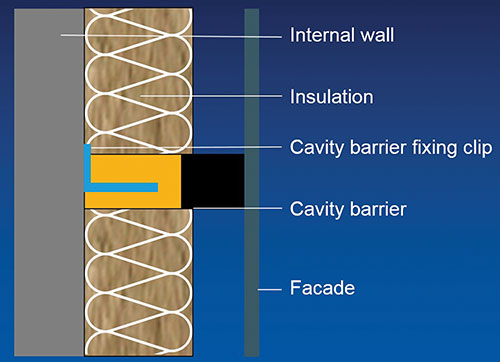

Dean notes that the main fire stop in façade terms is the perimeter fire stop – that being the special linear seal that closes the gap between the slab edge and the adjacent façade. The intention is to stop the products of a fire (not just smoke) moving vertically from one compartment to another. This is usually formed from a compressed insulating mineral fibre mass that either itself creates a seal against both adjacent surfaces, or is combined with an additional sealant to do so.

It is important to make sure that the portion of the façade adjacent to the fire stop (usually the spandrel zone) plus the bracket holding it all on, does not significantly deteriorate during a fire. Otherwise, the stability and even the existence of the perimeter fire stop are somewhat moot. Dean also adds that a similar, but not the same, fire stop is the cavity barrier. This aims to break up large cavities between a façade and the adjacent structure into small compartments to prevent the wide intra-cavity spread of smoke and hot gasses.

Examples of such scenarios might be a cladding wall built over a core or shear wall or a GFRC fin that runs up a column. The best practice is to add a horizontal cavity barrier at each equivalent floor level, and vertically at the perimeter of the area. There are several aspects to consider here, including that some cavities must be ventilated in general service. In such cases, a mineral fibre cavity barrier with an intumescent strip that expands in a fire to close the ventilation gap could be used.

Importance Of Compartmentalisation In Building Structure For Fire Safety

According to Sharma, fire stopping is part of effective compartmentation, it is the building of the fire, smoke, and other resistance-rated assemblies into “boxes” in buildings. These boxes are built to keep the fire from spreading from the room of origin to other parts of a building. Compartments are formed when the area or firewalls separate one space from another, allowing the collapse of one side without the other sides being structurally affected. They are also formed when resistance-rated walls are constructed in corridors, when resistance-rated floors are built for floor-to-floor protection, and when spacing between buildings is added to protect against fire spreading from building to building.

Thakur mentions, that apart from the material itself, the chimney effect at the cavity behind the façade is the main driver for the fire spread. Oxygen is the fuel of fire. So, cutting the supply of oxygen, in the cavity, is of the highest importance for extinguishing the fire. This is where compartmentalisation is importance. Appropriate compartmentalisation can alone contain the fire propagation substantially.

According to Stephenson, the purpose of compartmentation within a building is to protect the egress routes to allow safe evacuation and to limit the area where a fire could spread within a building. Depending on the hazard/risk, some rooms of a higher hazard or risk may require a higher level of fire separation based on the perceived risk, such that any fire should be contained within the room/ area of origin.

Material Fire Safety Standards

All fire stop systems need to be tested to two criteria – Integrity and Insulation (EI), notes Sharma. Integrity (E) refers to the ability of the system to prevent the passage of flame, smoke and combustible gases either through, around the material or through joints in an assembly; while insulation (I) refers to a measure of the increase in conducted heat transferred from the exposed to unexposed surfaces of 180°C rise above ambient.

Sharma adds that these two criteria are critical in the development of curtain wall perimeter fire stop products. The most effective products combine a number of material features – density, thickness, resin content, fibre structure and controlled compression – which together determine the resistance properties. When looking at the integrity (E) criteria, the material chosen must be impervious to the transfer of flame and gases, easy to install with minimal site management and accommodate all real world requirements at interfaces, joints and details.

Stephenson opines that the various fire safety standards can be applied and these will be governed by local code/standard requirements, such as the UAE Fire & Life Safety Code 2018 and also the requirements of the Authority Having Jurisdiction (AHJ), for example, the local civil defence. The standards to be achieved within fire codes generally refer to, but not limited to, British Standards (BS), National Fire Protection Association (NFPA) standards, Underwriters Laboratory (UL) standards, Factory Mutual (FM) standards and American Society for Testing and Materials (ASTM).

Dean says, “in the Middle East, we now have matured codes that define the minimum levels of performance required. However, noting that the materials are imported from all around the world and that there are already plenty of test standards available internationally, we use a variety of those standards to prove compliance with the codes. European and American standards are the most common; EN, BS, NFPA and ASTM”. He adds, the EN 13501-1 standard is followed because of its engineering basis, and because it evaluates multiple aspects and can be used across several material types is a common modern standard for classifying the important fundamental performance characteristics of a material.

However, we need to be careful about using this type of standard to state the performance of smaller components such as sealants and gaskets. These exist in the façade in a completely different arrangement than components such as cladding panels or insulation. Another important set of tests is the full system tests such as BS 8414, NFPA 285 or ISO 13785. These evaluate flame spread on a larger (system) level. However, they are still fundamentally RTF materials tests, and the incorporation of features such as windows into them, albeit anecdotally interesting, deviates significantly from the intent of the standards and introduces variables that present more confusion than conclusion.

Awareness About The Guidelines, Standards and norms For Fire Safety

Design and Execution Process of Building Construction Should Include Factors that can Avoid Damages, Even If a Fire Mishap Occurs

Design and Execution Process of Building Construction Should Include Factors that can Avoid Damages, Even If a Fire Mishap Occurs

Thakur observes that with the recent fire incidences around the world, there is better awareness on the subject. But the confusion is, who is responsible. It is a combined responsibility. The subject has some degree of uncertainty. Apart from codes and regulations that we need to follow, there are common senses and rationales that we need to consider while designing, selecting material and executing the façade. Also, design and execution should include factors that can avoid damages, even if a fire mishap occurs. The final objective should be the factors that challenge the fire and life safety subject should be eliminated and it should include factors that can save humans and property from damages.

The local laws, regulations and standards for fire safety should be known to all stakeholders within the built environment. It is important that a competent fire engineer is engaged on all projects to ensure compliance at all stages of the design, construction and occupation of a building, says Stephenson.

Dean points out that in the past, many buildings’ façades have been built without sufficient awareness of fire safety. Clearly one of the principal problems has been the spread of flame performance of voluminous elements of the cladding such as cladding panels or insulation. Similarly, fire stopping has been installed without sufficient evidence of performance and glass was installed without an understanding of post-breakage characteristics. However, particularly in this decade, with the introduction of codes and more importantly the enforcement of the application of those codes, standards of construction have improved substantially.

We are now building façades that are world-class in fire performance terms, but we must not ignore the previous building stock which definitely needs our retrospective attention. Conclusion With the introduction of new fire safety codes, the façade industry is undergoing several changes in the Middle East. The façade market is refurbishing and fire-rated façade materials are enjoying a huge share of benefits out of it.

Also, the market for fire rated materials has become more competitive with the entrance of new players. The initiatives are taken towards making the buildings fire-safe will boost the growth of façade fire safety materials and will provide tremendous opportunities to the players of this industry.