“What happens if there is a fire accident?”

“How have we correctly designed the components to react in the event of a fire?”

“Are we using the proper codes?”

“Are we answering the above questions when designing a façade?”

Accidents have occurred not only in developing countries but also in developed countries.

These accidents have occurred in places that are thought to be the safest, so why are we not alarmed?

The products used and how they react to fire should be the first consideration when designing a fire-rated façade. We have had a lot of debate in India, specifically, about the use of international codes, but we still don’t use them. The products in the Bill of Quantity (BOQ) are still referred to as “Class B, Class B1, Class A2, Class 1, Class 1A, Class A1, and so on”. The issue with such nomenclature is that we aren’t writing the testing parameters and code, so B, A1, and other such classes have no meaning. This creates an advantageous situation for manufacturers and contractors, who can easily tamper with quality. As a result, understanding the code and writing the proper nomenclature is critical, and the first step.

Understanding the Fire Code

- The five factors to consider when selecting a product for use in a façade are as follows:

Flame height - Fire propagation

- Smoke released

- Molten droplets

- Heat released

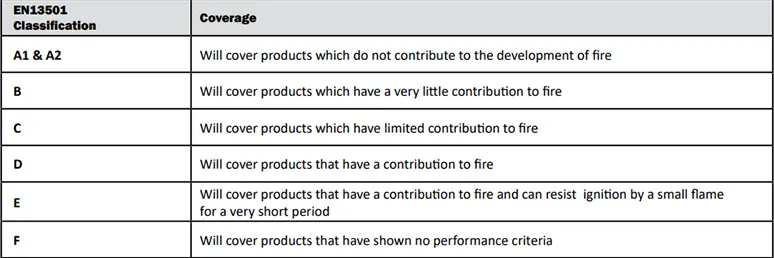

The code chosen should have the test methodology to check all the above parameters. One of such codes is EN 13501 which has test parameters to check all the above properties. Accordingly, a classification for products has been prepared:

So, depending on the façade, we can select a product that meets EN13501 Class A2 or Class B. It is also necessary to test the entire system that is being installed. The generic what we’re writing is still not a testing process, but rather a simple line like “the system should withstand fire for 2 hours”. Again, without a code or a testing procedure, this has no meaning. Codes such as NFPA 285 or BS8414 are available to test the entire installation. These tests are designed to simulate a real-world fire scenario and determine whether or not the entire system is capable of spreading fire. In this article, we’ll look at NFPA 285 as an example of fire performance testing for external cladding.

The following details are included in the façade design that passes the test:

- The product used for the façade shall be Class B or A2 in accordance with EN13501

- The details of structural support are provided

- The positioning of fire stoppers is depicted

This test evaluates the overall performance of the cladding system.

The key point to remember is that “if the product passes the test, it will pass in all scenarios” is not correct. Therefore, the report includes a detailed description of cladding, including all of its elements and the system’s design”. This means that if the product is installed with the same system, only it will pass the test and the situation will not become generic.

Certifications/Test Reports

Fire certification is specific to a product line. For example, if the alloy grade AA3105 is mentioned in the certificate, then the ACP of AA3105 is certified and not any other alloys such as AA1100, AA3003, AA5005, and so on that could be used to make ACP.

This means that the manufacturer may or may not provide you with a product with the same fire rating as AA3105. As a result, we must ensure the product range specified in the certificate. The product should be certified, and the validity of the certification can be checked with the certifying agency, as the certifying agency is required to make the certification public on its official website.

What to Add in the Bill of Quantity (BOQ)

We should always include the following two points for Fire properties in the product description and installation procedures in the BOQ:

-

EN13501-1 SBI Testing for checking Fire Growth, Smoke and THR The product must pass Class B (or any other classification depending on the cladding design) of EN13501 (the product’s fire code), and it must have a factory production certificate • that is valid for the duration of the project. If we simply write Class B, it could fall under any code description, which could be fire-related or not. As a result, writing the code is critical.

- The cladding design must pass NFPA 285 (or any other system test) and the system must be the same as shown in the test report; if there are any changes from the design in the test report, the contractor must submit a new test report with the changed system design.

- The code is important, and the specific design must pass the test. If the system design differs from what is stated in the test report, the design may or may not pass the test. These points would ensure that the product and design are fire safe. Also, generic statements such as “2 hours fire resistance” should be avoided because they have no meaning without a code and testing process.

Design Checks for Fire In the case of a façade, people usually check the system’s performance for water and air penetration. In addition, the system’s behaviour under a specific wind load is examined, i.e., whether the system is structurally stable under the calculated wind loads or not. However, few people check the performance of fire.

Manufacturers of components such as fire stop, insulation, rain screen product, and so on should be contacted when designing a fire-safe façade. They must provide the fire properties of their product and assist in the development of appropriate methodologies for making the design fire safe. The contractor should submit the design along with the system’s fire test report, just as he does for water penetration, air penetration, structural stability, and so on.

If using an older test report that has passed the fire test, the contractor should ensure that there are no changes in the location of fire stoppers, that the panel sizes remain the same, and that the thickness of the back support may be increased according to wind load, and that the number of screws used to attach the panels remain the same or increase and never decrease. Any of the critical products’ fire properties must also remain unchanged.

Conclusion

In the BOQ, product nomenclatures with complete codes should be used, and certification for the specific product being used should be requested. There should be no generic certifications accepted. When the product manufacturer requests system tests, the methodology and materials for installation must remain the same and should not be treated as valid for all construction and installation. The façade contractor must perform system tests for the specific installation methodology. These changes could provide 90 per cent relief from accidents turning into major tragedies, allowing us to save lives while also controlling property damage.