ABSTRACT

Shanghai Tower is a 124-level, 632m (2074ft) tower, with a gross floor area (GFA) of 380,000m² (4,090,320ft²) above grade. It is arranged in nine vertical zones and is shaped as a combination of efficient footprint with circular floor plates forming stacked cylinders from 12 to 15 stories in height “interrupted” with MEP/refuge floor areas that create zone divisions. These cylindrical shapes are enclosed with a rounded-apex triangle profile as outer skin allowing for introduction of a Sky Garden concept that utilizes the “dual skin” façade approach – atypical double skin façade.In considering the façade design, Gensler introduced a combination exterior and interior curtain wall system resulting in a high-performance façade, totaling 210,000m² (2,260,440ft²) of glazing area.

To refine the tower’s shape and respond to its location efficiently, a series of wind tunnel tests were conducted to measure the region’s largest natural forces: the typhoon and other strong prevailing winds. In developing these studies, various tower profile rotation and scaling options were analyzed. Complexities resulting from that process imposed significant challenges in defining an appropriate translation from building geometry to practical curtain-wall design and application. This paper traces the development of overall curtain wall system, focusing on exterior proposed design options, the issues associated with each of them and discusses the underlying decision-making that led to the final documented option.

1. INTRODUCTION

Shanghai is located at 120°51’~122°12’ east and 30°40’~31°53’ north, and it is in the eastern part of Asia. It is on the west coast of the Pacific Ocean, center point of the north and south coast in the Peoples Republic of China, on the edge of East China Sea. The prevailing climate is a subtropical monsoon climate with weather that is hot and very humid during summer. There are four distinct but mild seasons, full sunshine and plentiful rain. Outside atmospheric temperature range varies from 27F (-2°C) to 95F (35°C) with annual average temperature in the urban district of 64F (18°C). Humidity levels vary daily but are constant through the whole year.

Annual precipitation is more than 1440mm. Fifty percent of the annual precipitation is in the flood season between May and September. There are much more northwestern and southeastern winds throughout the year, and the annual average of sunlight is 1547 hours with insulation varying from 2.56 to 5.15 kWh/m²/day. Now under construction, the new tower is the third and final planned super high-rise building in Shanghai’s Pudong area that completes the development of the Lu Jia Zui Central Financial District. With a large program totaling about 540,000m² (5,815,000ft²) of built enclosed area – 380,000m² (4,100,000ft²) are above grade and 160,000m² (1,715,000ft²) are below grade.

The tower has been designed as a soft vertical spiral rotating at about 120 degrees and scaling at 55% rate exponentially. The tower functions as a self-sustaining vertical city. It is a mixed-used building of unique, vertically interconnected neighborhoods that evolve as the tower slowly rises towards the sky.

The building will include 120 floors plus four (4) additional floors of equipment rooms and Tuned Mass Damper (TMD). The top of the structure is at 632m (2074ft) height. The building is divided into nine zones with five main functions. The basic five main functions are:

- office;

- boutique office;

- luxury boutique hotel;

- themed retail, entertainment and cultural venues at the podium; and the

- observation experience at the tower’s pinnacle.

Within each zone there are atrium spaces that operate as activity centers, and a place of gathering for the people within their “zone” community. Additionally each atrium is designed to accommodate access by general public. The concept of the podium is to become activated with people, allowing uninterrupted public circulation between three adjacent “super-high-rises,” and be open and interconnected with the neighboring community.

2. DESIGN CONSIDERATIONS

2.1 Building Geometry

The tower’s profound twist expression is the Figure 2. Proposed Vertical Zone Division (Image by Gensler) result of its geometry. The tower geometry can be broken down into three (3) key components that are controlled in total by four variables.

- The first key component of the geometry is its horizontal profile (see Figure 3). The profile shape is based on an equilateral triangle. Two tangential curves offset at 60 degrees were used to create a smooth shape. This shape is driven by two variables, the radius of the large circle and its location relative to the center of the equilateral triangle (profile). It should be noted that the actual shape of the profile is independent of the remaining two key geometric drivers. As a result Gensler had the ability to look at the effect of modifying the horizontal profile and the impact such changes had on the tower form at all stages of the design.

- The second key component of the geometry is its vertical profile. The concept of the form is to take the horizontal profile and extrude it vertically and conform to the vertical profile. From a tower functional point of view, it was important to maintain a wide footprint for the lower 1/3 of the tower with a slender footprint at the upper 1/3 with a reduction of about 55% overall. This proportional distribution allowed for large lease spans within the office portion of the tower and smaller spans within the upper level hotel/boutique offices. Early in the design, it was found that a basic exponential curve provided the desired result. This is the same basic formula used in the finance industry for continuous compounding and/or discounting. Adjusting the two values in the horizontal profile and this third value in the vertical profile, we now have complete control of the vertical ratio, gross floor area and building form.

- The final key component is the rate of twist. This is a simple linear rotation from base to top. The fact that this final value can be changed independently allowed for great flexibility in the design stage, especially in selecting the best combined overall building performance.

2.2 Wind Tunnel Testing Results

Wind tunnel testing was essential for understanding building performance and was conducted at Rowan, Williams, Davies & Irwin Inc. (RWDI). The wind tunnel test procedures were based on requirements set out in Section 6.6 of the ASCE 7-05 Standard and the Load Code for the Design of Building Structures GB 50009-2001 for the P.R.C. Additionally, in order to predict the full-scale structural response and more detail pressure loads, the wind tunnel data were combined with a statistical model of the local wind climate. The wind climate model was based on local surface wind measurements taken at Hong Qiao International Airport and a computer simulation of typhoons provided by Applied Research Associates, Raleigh, NC. All testing was conducted on 1:500 model.

Additionally, the 1:85 scale model was tested for results of the Reynolds number correction factor that was used for more precise data on loading and the impact of wind vortex split on round exterior wall surfaces. The Gensler design team had anticipated that significant reduction in both tower structural wind loading and wind cladding pressures could be established if the building further improved its proposed geometry following the variables explained in section 2.1.

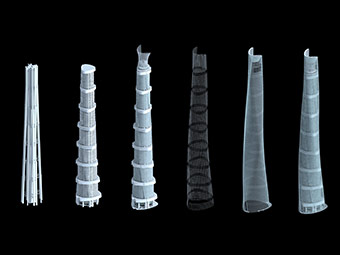

In order to establish the best possible case for reducing these loads, several scenarios were proposed involving rotation at 90°, 120°, 150°, 180°, 210° and then scaling off 25%, 40% , 55%, 70%, and 85%. All these scenarios were analyzed against each other and then compared to the base case scenario that was proposed in the form of a tapered box.

Results acquired through this process have shown that a scaling factor of about 55% and rotation at 120° can account for up to 24 % savings in structural wind loading and cladding pressure reduction as compared to base case of tapered box. This number equates to about $50 million (USD) in savings in building structure alone. Additionally, it helped optimize and distribute maximum cladding loads on the building while keeping desired aesthetics. Aesthetic concerns prevented the 180° rotation from being pursued, even though it would reduce loading by an additional 9% (see Figure 10).

Ongoing testing procedures included Reynolds number testing conducted with a final model at 1:85 scale. During this testing, constraints particular to the site were exemplified with Jin Mao and Shanghai World Financial Center, which combined together generate a localized increase in lateral turbulence intensity between 14% – 40%. During testing for the high Reynolds number, the following was concluded:

“While the positive pressures are unaffected by Reynolds number, the negative pressures could be increased at high Reynolds number. Approaching wind turbulence tends to reduce the Reynolds number effects. To account for potential Reynolds number effects for cladding design, it is recommended that the exterior peak negative pressures around the building corners determined from the 1:500 scale model tests should be increased by 10%. This correction is applicable to the upper third of the building. For lower portions of the building, the Reynolds number effects tend to be insignificant due to high turbulence levels. Similar corrections should also be considered in the structural wind loads for the curtain wall structural supporting system.” [1]

Final cladding loads testing results revealed that peak positive loads – pressure, are at about 2.0 – 2.5 KPa for about 97 % of the building with a 2.75 KPa maximum. Peak negative loads – suction, on the other hand, is at 4.5 KPa for about 85% of the building with 6.5 KPa maximum. Peak negative loads are distributed considerably around corners and at the upper building half towards the top. At the same time, the highest instant differential pressure between two subsequent curtain panels on the exterior wall can reach +/-1.5 KPa in either horizontal or vertical direction. Interior curtain wall cladding loads were at 2.1 KPa.

Here the Gensler team made an assumption in order to coordinate the erection sequence of Curtain Wall B, which will not see real wind-imposed pressures. The proposed curtain wall design strategy suggested addressing 85% of the negative 4.5 KPa with a standardized segmented unitized system that is uniform throughout the building’s exterior glass wall. Peak loads of up to 6.5 KPa corresponded to locations on the building where curtain panels were smaller in width due to the tower scaling factor on the same number of curtain panels per floor. This allowed the design glass thickness to stay uniform while vertical mullions were reinforced where needed to respond to high lateral stresses.

2.3 Curtain Wall Support System (CWSS)

Responding to an array of conditions in Shanghai, the Gensler team proposed a building design that employs a curtain wall system designed as a symbiosis of two glazed walls, Exterior Curtain wall–wall A and Interior Curtain Wall – Wall B with a tapering atrium in between. The main support for the Exterior Curtain Wall – Wall A is a horizontal ring beam consisting of a horizontal pipe 356mm in diameter laterally supported, at 10 meters on center in zone 2, and 7 meters on centre in zone 8 by a radial pipe strut support.

This variation is a result of the geometry that included tapering and rotation of the tower. The horizontal radial pipe strut supports consist of 219mm diameter pipe (with varied but mainly 22mm wall thickness) that transfers the exterior façade lateral load to the inner circular building slab edge. The radial strut pipes are rigidly connected with the horizontal girt, while using a hinge connection on the other side, at the interior slab edge steel support, to allow the exterior façade to move up and down relative to the inner structure.

To carry the gravity load of the façade and façade support structure, two 60mm to 80mm high strength rods (depending on the zone) are hung from the mechanical room/refuge area above, with a robust steel structure designed within, to the horizontal 356mm ring pipe beams at 4.5m (4.3m in zones 7 and 8) on center vertically at every strut location, including an amenity floor that uses steel bushing instead of perpendicular struts to limit lateral movement.

Steel bushing moves in vertical direction to allow for expected combined closing and opening movements to be largest at zone 2 with 114 mm. This is also where curtain wall system vertical expansion joint is located. In horizontal direction there are total of eight (8) expansion joint each allowing typically about 56 mm of combined open and closing movement. Special considerations were given to fire protective requirements of CWSS system and additional allowances had to be provided to total vertical and horizontal movements.

2.4 Energy Performance

The main feature considered for the exterior wall performance is based on a bioclimatic concept of a passive atrium system, where two skins are located in such a way as to create a large, full-height atrium space capitalizing on all benefits that are captured and, by natural convection of air, can be provide. Although a completely passive “greenhouse” effect could not be utilized alone for the atrium, there is minimal need for additional cooling and heating, and total thermal stresses and energy use in office spaces and the hotel are significantly reduced as confirmed in energy modeling.

Zones one through eight have three atria per floor that function together with an exterior and interior glazed skin to provide the level of thermal comfort desired for a built environment in Shanghai (zone nine is designed without both, interior curtain wall and atrium spaces).

This is done with a great degree of efficiency with only the first 15 feet of atrium mildly conditioned with use of perimeter Fan Coil Unit that either heats or cools, primarily during weather extremes, leaving the majority of the atrium to be ventilated with a combination of natural updraft and regulated top exhausts, as well as with spill air on the first and last floor of each zone. The whole system (inclusive of other LEED strategies in the building) creates about 21% energy efficiency compared to ASHRAE 90.1-2004 in LEED Rating, and about 12.5% over China’s nationally recognized “Three Star Rating”. Seven per cent of total efficiency is achieved as a result of various features used for exterior skin design (more in Chapter 3).

2.4.1 Prescriptive Constraints

Creating these inner atrium spaces to be vertically accessible public gardens and an integral part of a super high-rise building, as a building statement concept was in a way a pragmatically new idea that Gensler proposed.

Probably the best-known conceptual precedent is Norman Foster’s Commerzbank in Frankfurt. Shanghai’s considerably different climate with constant and high relative humidity (up to 95%), combined with prescriptive city codes that are used to define the required performance and make-up of exterior glazed wall components, provided a new challenge to the design team. Some of the requirements included: exterior wall glass ratio could not be more than 70%; reflectance out could not be more than 15%; shading coefficient had to be between 0.4 to 0.5, and if exterior glass created a conditioned enclosure, then makeup had to be with a K value of 1.5W/m²C. If the Exterior Curtain Wall A was to be considered as an enclosure for the conditioned space of the building then makeup for it had to be an insulated glass unit.

This created an additional challenge given the large size of glass panels varying from 2.2mx4.5m to 1.2mx4.3m. The glazing unit would have to be not only insulated unit make-up, impacting with that desired visual transmittance ratio (targeted very high up to 0.8), but would also require individually thicker glass lights in order to respond to high wind load peaks. In plane glass deflection had to be less than 25mm and with the insulated unit there was a danger of two lights touching each other at high peak loads, thus creating the danger of possible peak incidental breakage.

The idea of adding a spacer in the middle of the glass unit, although possible was not entertained. It has been calculated that if units were required to be insulated then glass had to be of a 15mm+ 10mm air+15mm make-up. This was a significant increase from the 12mm+SGP+ 12mm laminated make-up that was targeted.

At current weight, between 800 kg to 1000kg (2,200 pounds) per glass unit (the largest units at zone 2 and 3), this direction would result in an additional 25% increase in exterior glass weight. Ultimately, this would impact the curtain wall structural supporting system in its effective size and visual appearance in atrium spaces, as well as on individual member weight, which would also impact the total building weight expected to be approximately 850,000 metric tons, spiraling all the way to potential redesign of an already approved complex foundation system (including about 3500 piles at 1000mm in radius and 6000mm high matt foundation) on a limited site area.

It is common that the total exterior wall weight is within the ratio of up to two per cent of total building weight, however the intent of the design team was to truly follow principles of China’s Three Star rating based on implementing high-efficiency standards with reduction and multiple usage of individual members where possible – “Do more with less” [2].

After going through an extensive and complex review process with various client, city and government expert panels, it was determined that Exterior Curtain Wall A was to be considered as a weather enclosure for ventilated and unconditioned atrium space, and that true exterior wall is to be Interior Curtain Wall B. This allowed for Curtain Wall A to employ a laminated glass assembly and maintain efficient exterior wall weight ratio, while maintaining the desired transparency and glass area ratio. Additionally, various strategies were employed to maintain atrium performance at a comfortable level (See Figures 15 and 16).

2.4.2 Final Glass Selection

As final glass selection will be contingent to a series of mockups that are scheduled to be prepared in the next 12 months, the Gensler team has proposed the following generic glass types for two major curtain wall Systems:

Curtain Wall A: 26 mm laminated glass assembly: 12mm Low Iron +1.52mm SGP +Low E+ 12 mm Low iron. The upper 25 % of the panel will have a dissolving frit pattern from 75% down to 15%

Curtain Wall B: 30 mm insulated glass assembly 10mm Low Iron with Low E + 12mm air space + 8mm Low Iron. The middle portion of the panel between the “chair rail” to the finish floor will have a dissolving frit pattern from 15% down to 75% and 15% again.

3. CURTAIN WALL DESIGN OPTIONS

Curtain wall design development started as an exercise that at first attempted to resolve complex building geometry. The remainder of this paper will focus primarily on Curtain Wall A, analyzing ideas and various options, with an overview at the end of this paper on the current status of Curtain Wall B.

3.1.1 Curtain Wall A Studies

In developing resolutions for curtain wall geometry and final design, Gensler façade team used a variety of available software. This software involved scripting parametric flexibility in analysis. Early digital tools were Revit and Generative Components, however, later studies on the exterior walls were conducted exclusively through Rhino with Grasshopper parametric mechanism as well as 3D Max and AutoCAD.

This allowed for a constant precise geometrical understanding of the various exterior wall schemes being proposed and their relationship to building form. The following page with figures 19 through 22, captures the results of this complex study, highlighting the geometry involved. It should be noted that Revit was used as the main software for tower documentation and consultant coordination.