Lightweight aluminium curtain walling have become the façade of choice across the globe, however, they can present specifiers with a host of internal sound transmission issues that need to be addressed to ensure the well-being, happiness and productivity of building occupants. With the extensive use of specialist criteria, complex jargon and the many ways of referring to the humble ‘decibel’ – Rw, Dnf,w, DnT,w, Dnc,w – to name but a few, the world of acoustics can be confusing to those who are not involved in the subject. This can lead to misunderstandings, or worse, the misapplication of materials needed to achieve good acoustic standards or to solve sound transmission issues.

When considering the vertical transmission of airborne sound energy (floor-to-floor), the applicable criteria (regulatory or otherwise), will usually be in ‘dB’ in one of the following forms:

DnT,w – A Final Site Measured Value

A DnT,w is a final site measured value and will be controlled by both the ‘Rw’ value of the floor slab (direct sound transmission) and the Dnf,w value of the façade (flanking sound transmission).

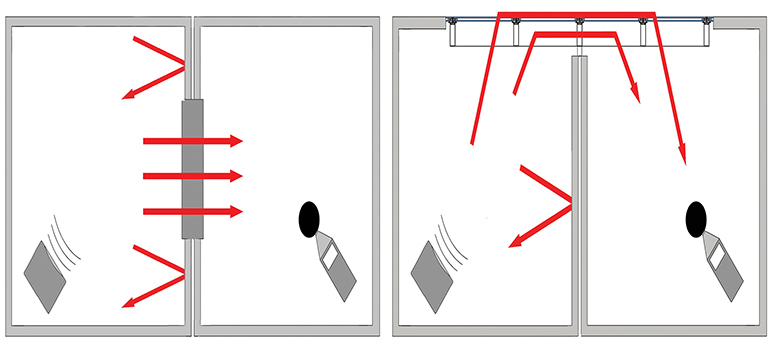

Rw – A Laboratory Tested Value For A Component (Figure 1)

An Rw value is a laboratory test value for a component or construction, such as a concrete floor slab, partition, window, door etc. The laboratory comprises of two fully isolated chambers, defined as the source room and receiving room, with an aperture between these 2 rooms. The sample material or construction is fitted into the aperture and the test is carried out. The acoustic performance between these chambers is very high, at least 10dB at all frequencies higher than the test specimen and therefore any sound energy that passes from one chamber to the other is considered to have travelled through the test specimen (Direct Sound Transmission).

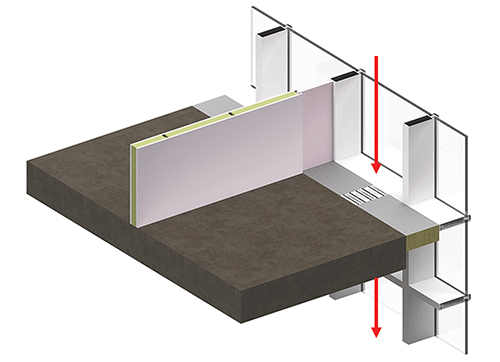

Dnf,w – A Laboratory Tested Value For A System (Figure 2)

A Dnf,w value is a laboratory test value for a system, such as a curtain wall system, raised access floor or suspended ceiling system. As with the laboratory configuration for the aperture testing, it comprises of two fully isolated chambers, but the apertures are adjacent to each other, rather than opposing. The sample construction is fitted across both apertures and the test is carried out. The acoustic performance between these chambers is very high, at least 10dB at all frequencies higher than the test specimen and therefore any sound energy that passes from one chamber to the other is considered to have travelled through the test specimen (Direct Sound Transmission).

It is essential to understand the important and significant differences between these to validate or otherwise prove potential compliance. In general, site measured values cannot match those recorded in a sound laboratory. The difference will vary depending on the method of test and actual performance levels, but as a guideline, 5-10dB minimum practical difference is commonly quoted.

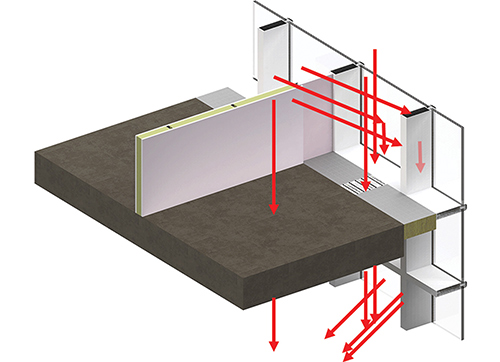

The 5 Common Flanking Paths For A Standard ‘Stick Curtain Walling System’

The Dnf,w value is a total flanking sound transmission of the façade system. It does, however, comprise several individual sound transmission paths with the 5 main path elements being:

a) the glazing element,

b) the transoms,

c) the structural element of the mullion,

d) the hollow of the mullion

e) the movement zone.

Several factors directly affect the overall performance, including the span between the mullions and transom, the stiffness, number of façade brackets, type of glass, glass orientation, twin or single mullion or transom designs and importantly the use of façade acoustic enhancement products.

The Glazing Element:

This transmission path occurs when sound energy in the source room hits the glass and becomes structure-borne by inducing vibrations in the glass. These vibrations travel into the gasket of the transom, into the transom itself, and then back into the spandrel panel via the second gasket. They then travel into the next transom (based on a twin transom design) and into the glass area which is remote from the source, finally re-radiating into the adjacent room.

Positive Factors

• Twin transom design

• Split transom

• High-performance glass

Negative Factors

• Single transom design

• Un-split transom

• Low-performance glass

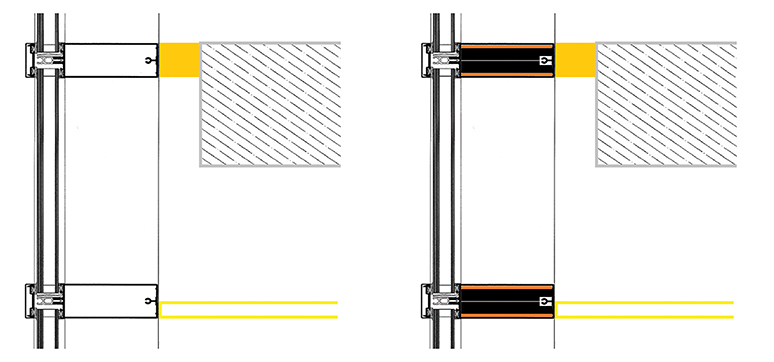

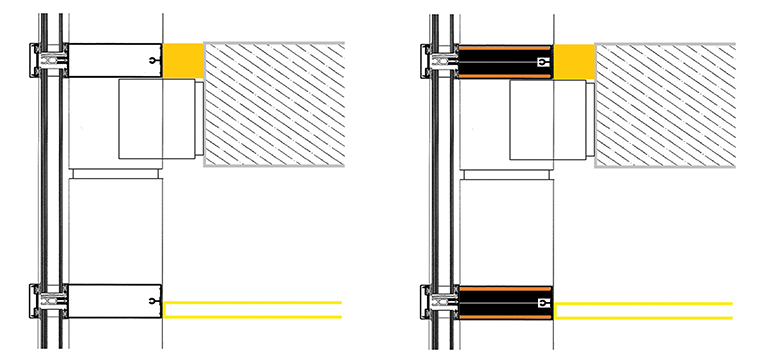

Transoms: This transmission path occurs when sound energy in the source room hits the transom, travels through the frame into the spandrel zone, past the floor slab. It then travels through the next transom (based on a twin transom design) into the adjacent room above or below. Single transom designs are generally significantly lower performing than twin transom designs. Use of high mass materials in-between the transoms, which can be incorporated into the fire seal specification, or use of specialist acoustic inserts inside the transoms can be particularly effective in reducing sound transmission via this path.

Image 5: Structure of mullion path | Image 6: Hollow of mullion path

Positive Factors

• Twin transom design

• High mass treatments

• High-performance fire seal

Negative Factors

• Single transom design

• Lightweight hollow aluminium

• Poor performing fire seals

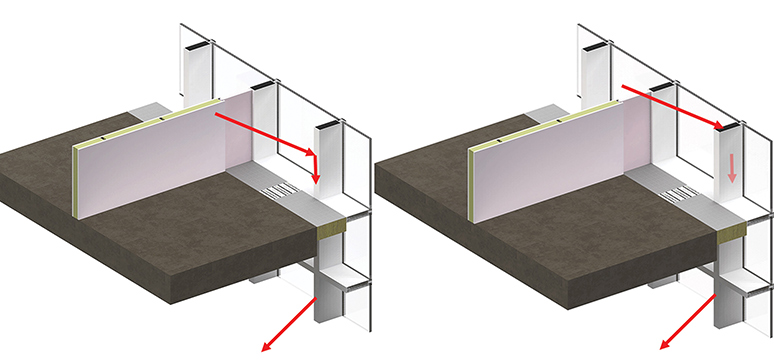

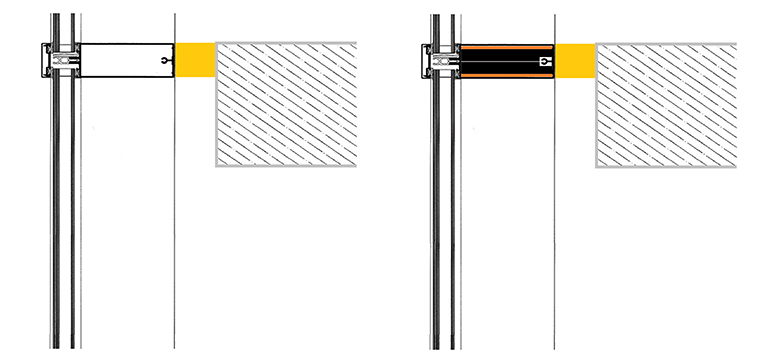

The Structural Element of the Mullion:

This transmission path occurs when sound energy in the source room hits the mullion and becomes structure borne by inducing vibrations in the aluminium. These vibrations travel easily up or down the façade and then re-radiates into the adjacent rooms.

Test data suggests that this causes the most issues in the 500Hz – 1000Hz range of frequencies, which is also where the human ear is most sensitive. Continuous mullions past the floor slab are one of the main potential ‘Performance Limiting Factors’ in façade design. The splitting and then re-joining of mullions with a joining spigot at the floor line show a large increase in potential overall performance, while fully decoupled mullions/framing at floor line show further improvement.

Positive Factors

• Decoupled framing

• Split mullions

• Damping materials

Negative Factors

• Fully connected framing

• Continuous mullions

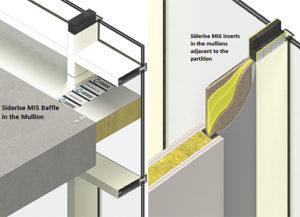

The Hollow of the Mullion:

This transmission path occurs when sound energy in the source room hits the mullion, passes through into the hollow of the mullion, a highly reverberant area, then travels up or down the building and breaking back out again into adjacent rooms above or below. Use of specialist acoustic baffles, either thin baffles based on high mass materials or purely absorption with a greater depth can be particularly effective reducing sound transmission via this path.

Positive Factors

• Baffles in the mullion at the floor line

Negative Factors

• Hollow section

• Continuous

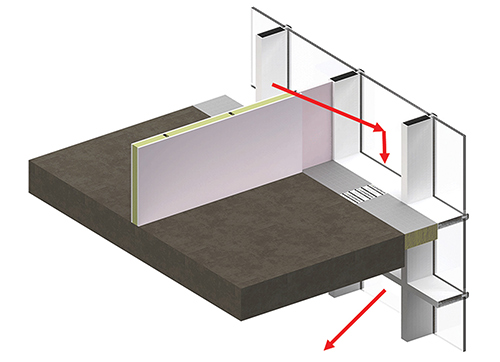

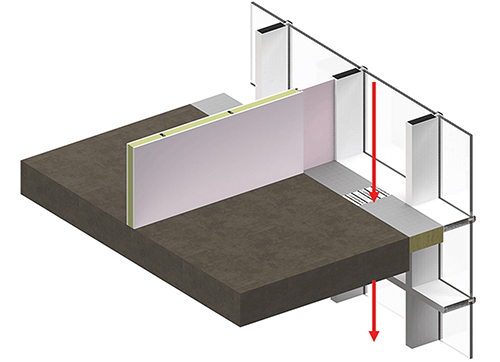

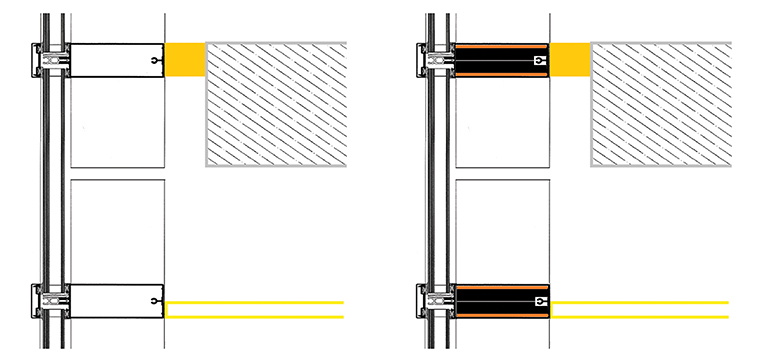

The Movement Zone: The movement cavity is a potential weak point when considering floor to floor performance and is often not included when façade testing is carried out in laboratories. Quite rightly, system manufacturers are there to test their system and not a proprietary fire stop, but when designing buildings these cavities are included and therefore It is important to recognize the potential for this to reduce the overall Dnf,w performance of the façade.

Commonly, interior linings, such as plasterboard ceilings, steel plates, floor screeds, raised access floor systems, are present and provide the additional mass required, but where ‘acoustic holes’ are present, such as roller blinds, air ventilation systems, recessed lights, lightweight suspended ceilings, lightweight aluminium closure plates etc., then the acoustic properties of the fire seal and acoustic upgrades are important.

Overall Performance

The overall performance is a combination of all these path elements and can only be established by full façade testing in an accredited laboratory, which can be time-consuming and very expensive. A project noise consultant can look at specific project details at the slab edge, compare the design with known library data and assess the possible overall performance.

However, this would not necessarily offer any guarantee of compliance. When assessing any design, it is important to understand that the overall performance would be wholly controlled by the weakest path element, referred to as the ‘Performance Limiting Factor’ and therefore any design change or acoustic enhancement should only be considered if all other path elements are capable of meeting the same value or being upgraded to meet the value.

For example, if a continuous mullion (Path ‘C’ above) is only able to achieve a maximum of 48dB Dnf,w then there is little point in improving the performance of ‘Path B’ to 55dB as, overall, it would still only be 48dB due to ‘Path C’ being the ‘Performance Limiting Factor’. Therefore, unless an improvement can be made additionally to Path B, for example, by splitting the mullion, there would be no benefit in upgrading any other path elements to above 48dB.

Performance criteria for commercial developments generally range between 40dB Dnf,w to 53dB Dnf,w, whereas residential developments range between 55dB Dnf,w to 65dB Dnf,w. Sometimes, however, for various reasons, values outside these ranges may be required. As such, it is essential to establish the precise project requirements and determine if +Ctr is applicable. This can usually be found in the project acoustic report.

Library Data (Vertical Sound Transmission)

Image 11A: CW broken with spigot and bracket | Image 11B: CW broken with spigot and bracket both T treated

Image 11A: CW broken with spigot and bracket | Image 11B: CW broken with spigot and bracket both T treated

Test data from various system manufacturers can help in understanding likely performance limiting factors. The values given below are based on library data and are for guidance. However, project-specific details should always be assessed individually and designs approved by the project noise consultant based on actual laboratory data or assessment by an acoustic engineer. Single transom, continuous mullion values range from 35dB Dnf,w (un-treated) to 46dB Dnf,w (with acoustic enhancements).

This type of detail is generally not ideal for residential developments but may be acceptable for commercial developments. Twin transom, continuous mullion values range from 42dB Dnf,w (un-treated) to 46dB Dnf,w (with acoustic enhancements). Overall performance is being linked by the continuous mullion. This type of detail is generally not ideal for residential developments but may be acceptable for commercial developments.

Twin transom, split mullion re-joined with a joining spigot, values range from 50dB Dnfw (un-treated) to 55dB Dnf,w (with acoustic enhancements). Overall performance has increased due to the mullion being split. This type of enhanced detail is likely to be acceptable for residential developments and may be acceptable for commercial developments without enhancement. Twin transom, split mullion, fully decoupled frame, values range from 50dB Dnf,w (untreated) to 65dB Dnf,w (with acoustic enhancements). Overall performance has increased significantly due to the fully decoupled frame. This type of detail enhanced is likely to be acceptable for almost all residential developments.

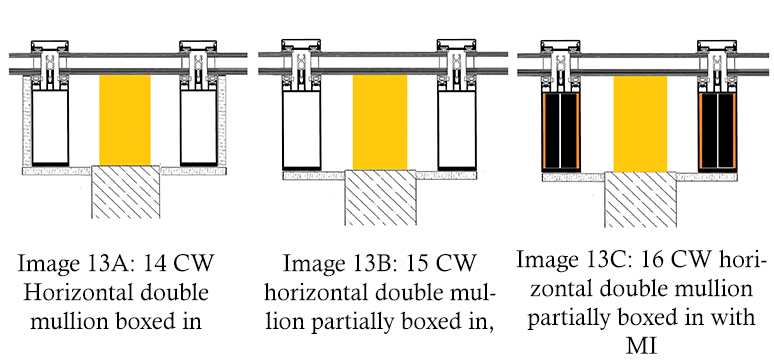

Library Data (Horizontal Sound Transmission)

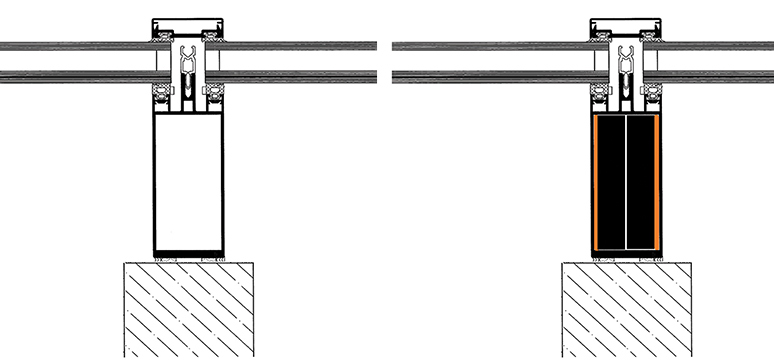

The values below are for guidance only. Twin Mullion configuration, partially boxed in, fully-boxed in, partially boxed in with acoustic mullion inserts values range from 50dB Dnf,w (un-treated) to 65dB Dnfw (with acoustic enhancements). This type of detail enhanced is likely acceptable for almost all residential developments.

Single Mullion configuration, untreated/empty, treated/acoustically enhanced, values range from 44dB Dnf,w (un-treated) to 53dB Dnf,w (with acoustic enhancements). This type of enhanced detail is possibly acceptable for residential developments, but if empty it is unlikely to be acceptable for commercial or residential

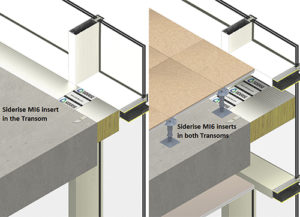

Twin Transom Designs

SIDERISE MI6 mullion/transom inserts in a twin transom design can increase the potential performance when high mass floors and ceiling abut the transoms, without the need to enhance the slab edge fire seal.

Single Transom Designs

Use of the SIDERISE MI6 mullion/transom inserts in a single transom design can increase the potential performance from circa 35dB Dnf,w to the maximum possible, 46-50dB Dnfw depending on the precise detail.

Mullions (Central To The Room)

Site test data suggests the use of the SIDERISE MI5 foam baffle in mullions central to the room can increase the site measured values by a potential of 2 – 4dB overall.

Single Mullions (Abutting Partitions)

The installation of the SIDERISE MI6 mullion/ transom inserts in a single mullion design can increase the potential performance from circa 44dB Dnfw to the maximum possible, 51-53dB Dnfw depending on the precise detail. The detailed product between the partition and the mullion is the SIDERISE FIP panel, with a performance of 46dB Rw and up to 1-hour rating.

Perimeter Barrier Fire Seal

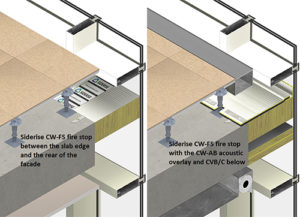

There are many the seal products available claiming compliance to common the standards. However, other equally important characteristics and properties of the seal should be considered when selecting the product: sound transmission performance, ability to expand and contract with the façade’s cyclic movement, a proven the performance (both integrity and insulation) when abutting deforming structures, provision of an effective smoke seal, resistance to moisture/water and ability to provide a flexible closure limiting possible flanking transmission.

Perimeter Barrier Fire Seal (Acoustic Enhancements)

In addition to the fully tested acoustic properties of the SIDERISE CW-FS system, the SIDERISE CWAB acoustic overlay and SIDERISE CVR/C10 lower barrier is fully tested with exceptionally high performances suitable for almost any criteria.

In a world where we are experiencing increasing noise levels, occupant complaints and dissatisfied clients, the acoustics in the built environment has become a concern to society and a challenge to designers.

It is all too common when considering the specification of the seal between the slab edge and the façade, for product selection to be based exclusively in terms of compliance to the relevant the regulations.

For façade engineers, architects and their clients, it is essential that due consideration is given to both the acoustic implications and performance of the closure arrangement, ensuring any potential weak point in curtain walled buildings is controlled. The use of performance-enhancing products will mitigate these issues.