Common Causes of Fires in Buildings

The potential reasons for fire to start are numerous. However, fire needs three elements to start, and a chain reaction to keep it going – heat, oxygen, and fuel. In WSP we tend to focus on the aspects of heat and fuel because oxygen is usually ubiquitous. Heat, in many respects, is synonymous with ignition, and fuel is a function of the quantity and availability of combustible material. So, armed with that information it’s easy to conceptualize the common causes, and they follow naturally. There are sources of fire that we humans intend to create – cooking, heating, and smoking are obvious. There are others that, although necessary, we don’t necessarily intend to create – electrical sparking resulting from flicking a switch being the most common, but also, when it goes wrong, the heat, sparking, and flames that result from a failing electrical unit.

It should come as no surprise then, that globally one of the most common sources of fire is faulty electrical devices. These can fail either with time, poor design or installation, or misuse/damage. The insidious danger lies in the fact that often electrical components are almost always concealed – in ceilings or within walls – but also usually within polymer housings – your computer, television, ceiling fan, coffee machine. The polymer, which is usually designed to be tightly packed around the electrical components, prevents access and is a great insulator, but it provides a ready source of fuel immediately available to any build-up of heat. Cooking is another common source of fire, for more obvious reasons.

In the Middle East, we are no different in this regard. However, like some other areas with similar climates, we have the additional aspect of ambient heat – which can dry out materials like waste, plants, and even potting compost to the extent that they become readily ignitable. Add a carelessly discarded cigarette or untended barbeque, and the results become both very apparent very quickly.

Ways to Reduce Fire Risks

Risk can be expressed as a function of probability and consequence, and in fire terms, these aspects can be generally aligned with ignition and fuel respectively. So, a methodical approach is to reduce either or both, and this is the main way that we in WSP demonstrably evaluate the current risk, and also the resultant effect of particular risk reduction measures – usually for existing building reviews.

However, from another perspective, risk can be reduced by good design, installation, and maintenance. Other factors are the quality or appropriate application of products.

One of the least expensive risk reduction opportunities is ‘use’. How we use our buildings, how we behave in them, and our knowledge of how to use them properly are tremendously important, and often don’t cost very much. Using the buildings or items in them for their intended purpose, not over stressing them or being careless with them, and training occupants to use them properly are key. Running electrical motors at their design speed, not smoking inconsiderately, and conducting regular fire drills would be examples of easy, and virtually cost-free wins. Mostly, not cutting corners, behaving sensibly, and being practical are the basics for risk reduction.

Role of Design Systems in Fire-Safe Buildings

Fire safety, in the context of the façade, starts at the design stage. This must be a collaborative and coordinated process, along with the other technical disciplines and architects to ensure that the design aesthetic intent is met, with the technical performance required.

That conversation should start as early as possible, whilst opportunities remain broad. As the design is refined in the transition from concept to construction, those opportunities become narrower to nil; so giving the correct design direction early is essential. This is the case for new designs on new buildings – existing buildings are a different matter of course.

Role of Fenestration Design in Fire-Safe Buildings

The purpose of the façade is to both separate the inside from the outside and also to give us controlled access to it.

We need to protect ourselves from the external environment, in its varying forms, but also we need to let in light, provide a view (in both directions), and provide openings so that we can get in and out and ventilate our internal spaces where appropriate.

All of that needs to be done safely. In ignition and fuel terms, we need to limit both. The ignition aspects are usually not part of the façade design, so generally, the most we can do is protect ourselves from them by ensuring that electrical elements are properly separated, conducted, and earthed and that our façade is itself properly earthed.

However, we have more control over the fuel aspect. Providing a ‘non-combustible façade’ is an unlikely proposition – we unavoidably need polymers in most façades for seals, and coatings. However, the selection of materials for panels and insulation is critical.

These are the big-ticket items – the large volume, large surface area components that result in large fires and rapid flame spread if not selected knowledgeably.

The other key aspect is compartmentation – breaking up cavities so that they are discontinuous. We do this using perimeter fire-stopping and cavity barriers, but a good façade design will do that naturally as well.

Passive & Active Fire-Safe Protection Methods

Put simply, passive systems are where there are no mechanical moving parts, fluid reservoirs, or the like that become active in a fire. They might include doors, walls, floors, ceilings, perimeter fi stopping, or cavity barriers. They would also typically relate to the nature of materials themselves, in the context of their ignitability, the propensity to burn or spread flame and create smoke or block the products of fire.

Conversely, active systems include arrangements such as sprinklers or other suppression systems, detection systems, alarms, or other reactive control arrangements.

Clarifying those general categories, doors have to be opened and closed, and intumescent materials will ‘activate’ when heated – expanding to fill a seal or void – but these are effectively still passive systems because their function is primarily associated with their performance in their static state.

Whilst there are some active systems for façades, the primary performance should aim to be passive. Using a flammable material for a façade, which needs an additional active system to extinguish it in the case of a fire is costly and adds risk – what if the active system doesn’t work? Façade fires will often overcome sprinkler systems if they extend over and break into multiple floors

Reaction to Fire & Fire Resistance: Classification of Materials in the Event of a Fire

Just like any other part of the building, façade fire performance falls into the well-established categories of Reaction to Fire (RTF) and Fire Resistance (FR). Understanding what these are and how they affect a façade is critical. In brief, RTF is how and if materials burn. FR is the compartmentation of a fire. I can’t think of a scenario where the consideration of both categories isn’t required in all buildings to some extent. These categories themselves are fundamentally passive processes; as opposed to active processes.

Scenarios that Can Cause an Internal Building Fire to Spread to the External Façade

For most parts of buildings, façades are not fire-resistance rated. One of the most common fire break-out scenarios is through glazing. All fires are different, and there are many factors that will affect when the glass breaks and what happens afterwards. Glass can typically break anywhere between 200 and 400 °C, and may or may not immediately fall out, depending on the type. However, distortion in the frame may break glass beforehand, or retain the glass until the frame itself melts (at circa 660°C in the case of aluminium). However, this all happens within minutes in a fully developing fire and it would be reasonable to expect some level of fire breakout after 10 minutes.

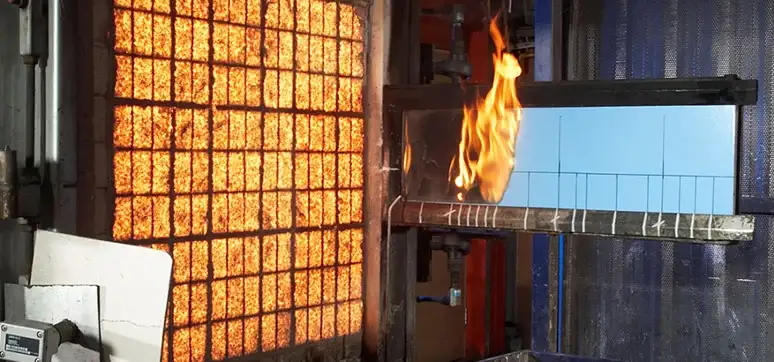

It’s worth noting that NFPA 285, a common fi re-test that simulates a fully developed fire breaking out from a façade or window opening, introduces an external burner at 5 minutes into the test.

Once there is external impingement of flame, the level to which fire spreads will depend on two principal factors: the extent to which the external façade material supports combustion and flame spread, and whether the fire breaks back into the façade through at the next level, igniting materials in the next room above (leapfrog effect). This progression could occur as a result of the materials on the outside of the façade, but also materials within the façade, such as insulation, if they are combustible too. Limiting the combustibility and flame spread characteristics of such materials is the main measure employed to prevent significant spread. Other options are introducing fire breaks – sections of the wall that will not allow flame spread, or the introduction of horizontal projections to block the vertical path of the fire.

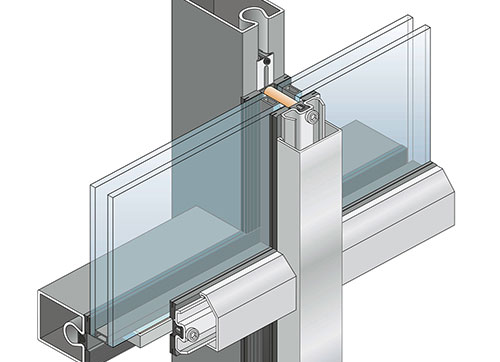

The second form of spread is within cavities in the façade. If hot gases are allowed to travel through spaces within the façade, these can cause fires in any location that the gas can get to. A good design will include cavity barriers, that literally block the flow of gasses – typically at least at each floor level vertically, and between dwelling units horizontally. A third significant form of spread is at the interface where the horizontal floor slabs meet the vertical façade. This is actually an internal-to-internal spread. We use perimeter fire stopping – a specialized linear joint seal – to prevent this passage. See below.

The Importance of ‘Perimeter Fire Barrier Systems’ in the Prevention of Fire Spread

The main fire stop in façade terms is the perimeter fire stop – that being the special linear seal that closes the gap between the slab edge and the adjacent façade. The intention is to stop smoke and hot gasses from moving vertically from one compartment to another. This is usually formed from a compressed insulating mineral fiber mass that either itself creates a seal against both adjacent surfaces, or is combined with an additional sealant to do so. It is important to make sure that the portion of the façade adjacent to the firestop (usually the spandrel zone), plus the bracket holding it all on, doesn’t significantly deteriorate during a fire. Otherwise, the stability and even existence of the perimeter firestop is somewhat moot.

A similar, but not the same, firestop is the cavity barrier. This aims to break up large cavities between a façade and the adjacent structure into small compartments to prevent the wide intra-cavity spread of smoke and hot gasses. Examples of such scenarios might be a cladding wall built over a core or shear wall or a GFRC fin that runs up a column. The best practice is to add a horizontal cavity barrier at each equivalent floor level, and vertically at the perimeter of the area. There are several aspects to consider here, including that some cavities must be ventilated in general service. In such cases, a mineral fiber cavity barrier with an intumescent strip that expands in a fire to close the ventilation gap could be used.

The Choice of Materials Considering Fire Safety Buildings

Expanding on the RTF and FR performance categories, and taking RTF (reaction to fire) first, we need to make sure that the façade materials are not easily ignitable – and irresponsibly discarded cigarettes for example shouldn’t be able to start a façade fire.

Surface spread of flame would be our next concern – if a façade is next to fire maybe it will be burned but the materials that the façade is built from shouldn’t then spread that flame outside the zone of the original fire.

As materials burn they give off various chemicals in the smoke, and some smoke is denser than others. We should use materials in our façades that limit the toxicity and density of their combustion gases. Finally for RTF, combustibility. Those that have called for ‘façades to be non-combustible don’t understand façades and don’t understand fire. ‘Non-combustibility’ has a very strict definition in the fire industry and only materials like glass, stone, solid metal, and the like can achieve it. However, we need gaskets, sealants, thermal breaks, and other plastic/polymer materials for the façades to work properly. Although the performance of these small components should have some understood limits, if all other aspects of the façade are controlled, then the small, necessary combustible components have an equally limited effect.

Turning to FR (fire resistance) or compartmentation, the fire safety strategy created by the fire consultant informs the façade consultant where the fire stop should be and if a façade itself needs to be fire-resistance rated.

Common examples are horizontal firestops between the slab edge and the façade; the spandrel panel itself (so that the spandrel panel doesn’t deteriorate in a fire); vertical fi stopping between party walls and the façade; and car park entrance glazing. The requirement for other façades to be FR-rated is less common. It’s important that all of these aspects work together to collectively create a system that is low-risk.

Façade Openings, Ventilators, and Other Façade Designs to Prevent Fire and its Spread

As we all know, heat rises. In a fire, this is also the case, and as the hot gasses ascend, they will gather at whatever ceiling they reach above them. The gases themselves then form a large volume radiating heat, especially if the ceiling materials are combustible and are ignited. That hot layer of gas grows and deepens, and radiates more heat. At a certain point, the radiation will be sufficient to ignite other elements – perhaps furniture and carpets. The hot layer is also likely to increasingly reduce the opportunity for escape beneath it, as it swells downwards and increases in intensity.

Consequently, a common approach is to ventilate the hot gasses. This limits the depth of the hot layer and the intensity of radiation. The objective is to prevent flashover – the point at which all materials in the space become involved in the fire – and potentially allow spaces below to be tenable for longer – even as a means of escape.

This adds more importance to ensuring that the façade materials are themselves highly performing. Ventilating hot gasses onto a façade that burns would not be a well-considered design.

There are many proprietary systems that are specifically designed to ventilate hot gasses in the case of a fire, and these can be connected to building management systems accordingly.

The Current Fire Safety Codes for Buildings in the Middle East

The current fire safety codes for buildings in the region have had a transformational effect on the fire performance of façades. Prior to their introduction, there were many examples of inappropriate designs and materials or systems selection. We are often dealing with that legacy now.

However, the new codes are clear, easy to follow, and world-class. Importantly, most of them draw together best practices from around the world and in many cases enhance and exceed them.