Powder coating is a metal finishing process mostly on industrial equipment. Powder coating is applied as a dry, free-flowing, colored powder to a fabricated part through an electrostatic process, then curled with heat. Powder coating is a flexible and durable solution and protects a range of substrates. The process is suitable for both indoor and outdoor applications, and it’s one of the most used types of finish in the world.

Powder Coating Process

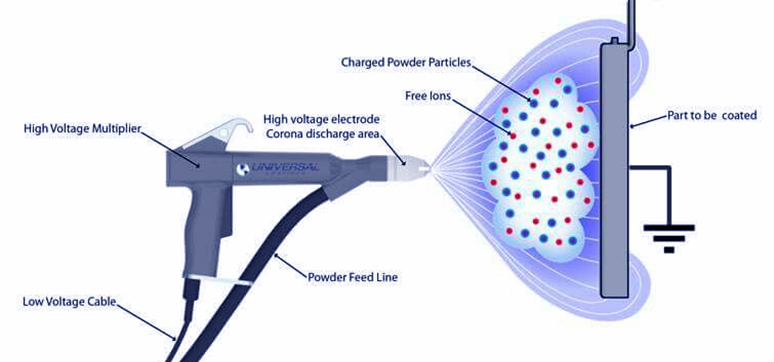

Surface Preparation is the first step of the process and perhaps the most important one. This entails getting rid of all contaminants lurking on the surface and promoting coating adhesion. Preheating the workpiece achieves a uniform finish, and can enhance durability, and corrosion resistance. The material being coated is then sprayed with the powder coating material using an electrostatic gun that imparts charged particles onto the surface of the substrate.

The next step in the powder-coating process is curing, coated product is then passed to the oven where the chemical alteration of the powder coating takes place and the bonds solidify.

One of the most significant advantages of using powder coatings over liquid paints is that once solidified, more layers can be added. Thicker coatings mean longevity and more protection.

Types of Powder Coating

There are two types of powder coatings, thermoplastic, and thermosets.

Thermoplastics are manufactured from synthetic materials that can be formed multiple times. High temperature can melt thermoplastics, therefore this process makes the powder coating both reversible and reusable. However, thermoplastic powders are favored for their wear and chemical resistance.

Thermoplastic powder coatings include:

- Polyvinyl Chloride (PVC)- PVC coatings are sleek, durable, and are good for various forms of insulation. They possess a good balance of properties and are used on dishwasher baskets and in food contact applications.

- Polyolefin- Polyolefin finishes are highly resistant to abrasives and chemicals, and offer a smooth surface and excellent adhesion properties. They are mostly used as coatings for laboratory equipment.

- Nylon- Nylon powder coatings are durable, provide excellent chemical and solvent resistance, and is FDA approved for food contact.

Thermosets go through a chemical cross-linking reaction that is non-reversible when baked, altering the physical properties of the powder coating. They cure harder than thermoplastics and provide a high level of resistance to heat. This type is much cheaper as compared to thermoplastic powder coating.

Thermoset powder coatings include:

- Epoxy- Epoxy-coated surfaces are durable, tough, and electrically insulative. However, they are brittle, when exposed to UV rays, and cause fading, chalking, and other surface-level degradation.

- Epoxy-Polyester hybrids- The use of Epoxy-Polyester hybrids, softens the epoxy coating, which is less likely to chip or crack. They are used for decorative applications including office furniture, fire extinguishers, and toys.

- Polyester- Polyester powder coatings offer strong adhesion properties, impact strength, and weather resistance. They are widely used for outdoor applications such as patio furniture, lawnmowers, building exteriors, and several car parts.

- Acrylic- Acrylic powder coatings are good for UV light resistance and leave a super gloss finish, making them an ideal option for automotive parts, such as wheels and exposed engine parts.

- Silicon- Silicone-based powder coatings are often used on products that can withstand high temperatures of over 1,000 degrees. Some of these products include gas and charcoal grills, automotive and motorcycle parts, fireplace inserts, and lighting fixtures.

Powder Coating Applications

Powder coating has applications in diverse industries. The coated product has corrosion protection, scratch resistance, and aesthetic appeal. Powder coating is used for external architectural features such as metallic roofs and curtain walls, this makes sure that they retain their surface appeal for the longest time possible. Moreover, it also provides a protective coating to street furniture such as road and direction signs.

Powder coating protects agricultural implements, industrial machinery, and metallic outdoor furniture. Most high usage car parts, such as door handles and bumpers, are also powder coated.

Advantages of Powder Coatings

- Environment-friendly- In today’s era where environmental regulations are essential for all industries, the powder-coating process offers an eco-friendly alternative to liquid painting and other metal finishing techniques as it is reusable and recyclable. Mostly, it is used precisely with minimal wastage, unlike paint, where you experience a lot of oversprays.

- Cost-efficient- The powder-coating process is extremely cost-efficient and is available in a wide variety of colors and specialty effects to produce the desired appearance of the product. Powder coating prices are cheaper than wet paint and result in lower energy and disposal costs.

- Polished Finish- It provides a tougher and polished finish than conventional paint and a higher level of durability to corrosion, tarnishing, chemicals, moisture, and other elements.

Powder coating finishes are the most used protective finishes when it comes to metal fabrication. Therefore, it’s important to acknowledge types of powder coating when deciding what types of powder coating services are best suited for specific applications.

Writer Credit: Ar. Jahnavi Malhotra