Energy Efficient Facade Systems

Energy consumption in the Middle East countries has been rising over last four decades. The residential building sector alone accounts for more than 50% of all delivered energy consumption, and half of this is attributed to use of air conditioning for cooling. Better building design triggered by better ventilated facade performance could drive down this energy use considerably.

In recent years, ventilated facade systems have found widespread use in various climatic zones due to their high energy performance, rich variety of available design solutions, reduced effect of solar radiation on indoor micro climate, good noise reduction properties, and possibility of rapid building repair and reconstruction.

The ventilated cladding however, is just the façade. From an insulation perspective we are interested in making sure that beneath that façade, there is something working hard to ensure the building you are designing stays durable, useful and beautiful. Selecting products can often become habitual, particularly if those products are never going to be ‘seen’.

But, if you want your insulation to quietly do its job for decades to come, it is important to consider all of the elements that will impact on the performance of the system.

Specifying the right cladding system then, should not just be about what will look the best, it should be about making sure the hardest-working part of the cladding system – the insulation – is performing to its optimal level, delivering thermal performance, acoustic comfort and peace of mind when it comes to reaction to fire.

How Ventilated Facade System Work

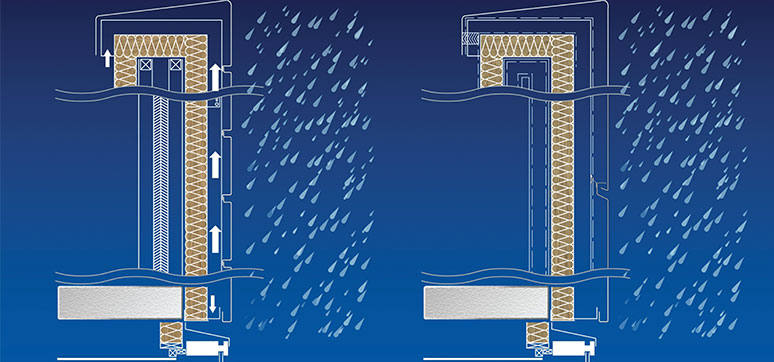

Drained and Vented: Drained and vented ventilated facade systems are not weather tight, with an open cavity to the top and the bottom. The top air cavity is protected with an overhang to minimize moisture entering and a moisture barrier is used to protect the building structure.

Vented and Pressure-Equalised: Vented and pressure equalized ventilated facade systems are most commonly used on tall commercial buildings. They are designed to prevent moisture from entering into the air gap between the façade and the internal structure.

This works by sealing the top section of the façade and creating separate ventilation cavities. When wind tries to drive moisture into the ventilation gap, the air in the cavity resists – equalising the pressure. The ventilation gaps also allow moisture to drain from the cladding system.

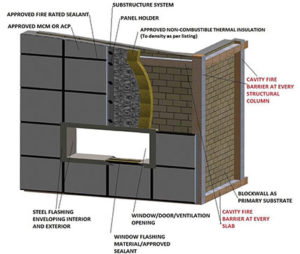

In addition to the air gap which acts as a water barrier, other important elements of a typical ventilated façade include:

• An inner leaf usually comprising a 200 mm block wall

• A vapour control layer

• Non-combustible insulation

• Insulation close – butted and fixed independently against the building substrate using proprietary insulation fasteners

• Aluminum support brackets fixed back to the steel studs with a thermal break pad incorporated between the brackets and the sheathing board

• Support rails fixed to the brackets to support the final cladding layer

• The façade

Thermal Performance

Working Hard Beneath the Surface Thermally, aluminium bracketry used in ventilated systems is over 4,500 times more efficient at conducting heat than the insulation it penetrates.

It is therefore no surprise that the heat flow paths through ventilated facade systems are complex and cannot be accurately quantified by the normal calculation methods used to establish the U-value of a construction element, namely BS EN ISO6946 (building components and building elements – thermal resistance and thermal transmittance – calculation method).

Not only does this make the thermal performance of the insulation you incorporate into your ventilated system more important, it also makes the way it is calculated that much more complicated.

BS EN ISO6946 states “when an insulation layer, or part of an insulation layer, is penetrated by a metal component, other techniques (for calculating the U-value) should be used”.

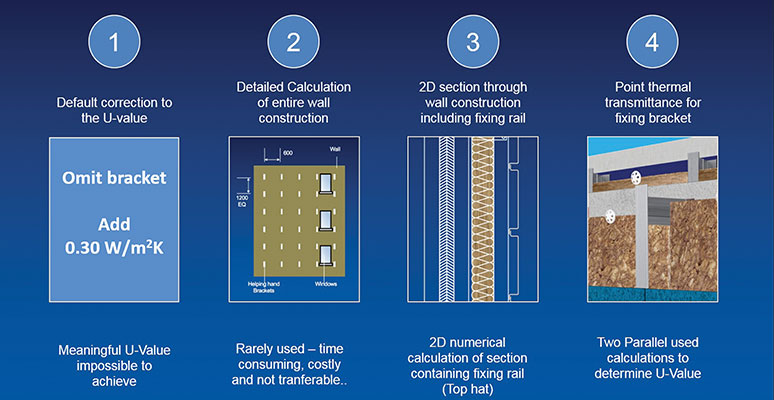

The following methods are available for the facade designers :

• Detailed calculation for the whole wall: The first of your options is to numerically model the full ventilated facade elevation or elevations. This method is rarely, if ever, favoured due to i) cost, ii) time, iii) lack of transfer-ability.

• Linear thermal transmittance for a fixing rail that penetrates an insulation layer: This involves a 2D numerical calculation on a section through the wall containing the fixing rail. This methodology is specific to ventilated systems, such as those that employ a ‘Top Hat’ section

• Point thermal transmittance for a discrete fixing bracket that penetrates an insulation layer: In this option parallel calculations are carried out:

o 3-D numerical calculation of a section through the wall containing a representative fixing bracket

o Calculation without the fixing brackets.

This enables the point thermal transmittance of the bracket to be calculated (and easily replicated in calculations using the same bracket and insulation combination)

• Complete a default correction to the U-value: Without numerical modelling, the U-value is calculated without brackets and increased by 0.30 W/m2K to compensate. Any meaningful U-value is therefore impossible to achieve.

As an example, a system involving fully filled 150mm light steel frame studs, 100mm of mineral wool insulation, and brackets at 1200 x 600mm centres, correctly calculated would give a U-value of 0.19 W/ m2K. Using the default calculation the value would be increased to 0.49 W/m2K.

Exposure To The Elements During Installation

It is relatively common for the insulation to be left open to the elements before the cladding is applied. This leaves insulation vulnerable to rain and weather damage regardless of the material used.

According to Metal Cladding and Roofing Manufacturers Association (MCRMA):

• ‘Insulation products should not be installed while wet or into constructions which have become wet’.

• ‘Where the product is being stored for any length of time, the product must be protected from the elements’.

• ‘It is good building practice to ensure insulation products should be installed in a dry state’.

Fire

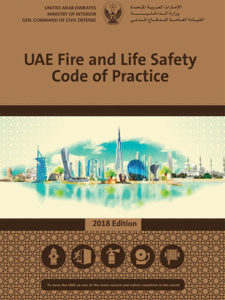

Fire performance standards are detailed in UAE Fire Life and Safety Code 2018, Chapter 1, Part 4 Façade and Exterior Wall Covering Systems, and this contains specific guidance on the fire performance testing of ventilated cladding systems.

Why Fire Spread is Significant?

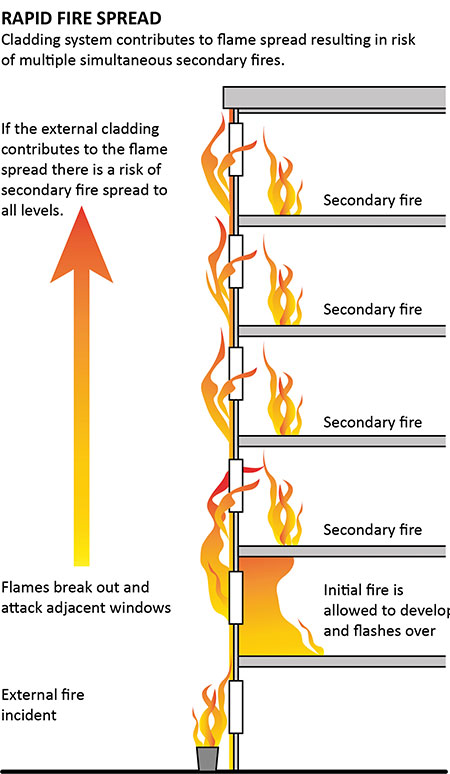

If the fire spreads through the cavity unchecked, it can spread rapidly through the building, reaching other floors via window openings and repeat the process.

Fire Spread Through Cavities

In some circumstances, fire can spread through cavities within external cladding systems. These cavities can be part of the system design, such as ventilated cladding, or be formed by the delamination or differential movement caused by the fire itself.

The fire performance of the façade itself is an area of contention currently. Some industry players suggesting that ADB 12.7 should apply i.e. at or above 18m the façade should be Euroclass A2 or better.

Others citing Diagram 40 and observing Euroclass B. The CWCT (Centre for Window and Cladding Technology) is due to publish a multi-party statement on this topic shortly. For absolute confidence the façade should be Euroclass A2, limited combustibility (or better).

In the event of a fire, whilst the original flame length may be fairly short, it can extend a long way into acavity. Non-combustible insulants (e.g. rock mineral wool) provide a further degree of safety if, for instance, cavity barriers have not been installed, or if they have been incorrectly installed and fail to work in the intended manner.

Regardless of insulant type, cavity barriers are critical to the fire performance of any ventilated façade and are addressed in UAE Fire Life and Safety code “Fire Stopping” chapter.

Cavity barriers should be made from non-combustible material and should:

• Be at least 100mm high

• Penetrate the full depth of the insulation

• Form a continuous barrier through the insulation layer

• Provide at least 120 minutes fire resistance and Insulation

A number of cavity barriers are available in the market, which employ the use of intumescent strips or coatings in order to seal cavities. Typically fire barriers are manufactured from rock mineral wool, the same material that can be used to insulate the building.

As a ventilated system relies on the provision of a ventilated airspace in order to function properly, the cavity barrier cannot fill the full width of the cavity. Proprietary cavity barriers exist that, typically, comprise of a foil faced intumescent strip attached to a strip of rock mineral wool. In the event of a fire the intumescent strip expands to fill the ventilated airspace and restrict the movement of hot gases and smoke as far as is practicable.

Restricted Fire Spread

With fire barriers correctly installed, the cladding system does not contribute to flame spread and the risk of secondary fires is significantly limited.

High Rise and Super High-Rise Buildings

The UAE Fire Life and Safety Code specifies, ‘the minimum requirements for the classification, combustibility, surface burning and flame spread ratings, design, installation, inspection, and maintenance of exterior façade wall cladding, balcony coverings and components such as, metal composite panels, aluminum composite panels, polycarbonate panels, EIFS, ETICS, glazing, insulation, sealants, etc.”3

The code goes on to say “The external envelope of a building should not provide a medium for fire spread if it is likely to be a risk to health and safety. The use of combustible materials in the cladding system and extensive cavities may present such a risk.” Special consideration is given to super high rise and public buildings. To satisfy the requirements of the building regulations, designers have to comply to with below:

• “In a building with a storey 18 metres or more above ground level, any insulation product, filler material (not including gaskets, sealants and similar) etc. used in the external wall construction should be noncombustible.”

• Meet the performance criteria given in an “Assembly Test”. This criterion uses full scale test data from BS 8414-1:2002 (masonry substrate) and BS 8414-2:2005 (lightweight systems) or NFPA 285:2019 (lightweight system).

Upon selecting this route, it’s critical that you are designing and constructing the exact build-up that has been tested, being mindful that variances in any element, such as insulation thickness, sheathing board and façade will compromise system compliance with potentially significant ramifications in performance, time and cost.

• UAE Fire Life and Safety code offers a third option stating, ‘Engineering Judgments (EJ), if any, shall be permitted where Civil Defence has no objections. Such engineering judgment submissions to Civil Defence shall be prepared and stamped jointly by main consultant, house of expertise, cladding component, façade system manufacturers and façade installers”.

The report should be supported by test data which the test-house already has in its possession and so this option may not be of benefit if the products have not already been tested in multiple situations / arrangements. The report should also specifically reference the tests which they have carried out on the product.

With this and the previous method of compliance, any damage to the system in use or later modification of the building may have an impact on the relevance of the fire test results and the criteria that were considered when undertaking a desk study.

Acoustics

Thermal performance is usually the first consideration when an insulation solution is being considered. However, its reaction to fire, especially within ventilated systems is assuming equal importance. Also increasing in significance is the acoustic performance, and its ability to reduce noise from passing through the system.

Designing a quiet internal working environment is a particularly important element of building design for schools to enhance learning, offices to maximize productivity, and hospitals to aid patient rest and recovery. When considering the acoustic performance of the ventilated system, and choosing an appropriate insulant, it is important for the designer to consider sound absorption as well as sound insulation.

Sound Insulation

Sound insulation is important where internal working environments require external noise sources to be reduced, or where the use of a building generates a significant amount of noise which needs to be prevented from breaking out to the external environment.

Most of the sound reduction provided by a ventilated façade system is achieved by reflecting the sound back towards its source – whether that be to prevent external noise from entering the internal environment, or by reflecting the noise generated inside a building, and preventing it from breaking out of the building to the surrounding area.

Sound Absorption

Sound absorption occurs where sound energy is absorbed by ‘acoustically soft’ materials which take in sound energy and transform it into heat, as opposed to being reflected by ‘acoustically hard’ materials.

Sound absorption is particularly important where the internal environment may generate noise which should be prevented from reverberating within the building. Mineral wool insulation provides a high level of absorption and is often used to absorb the sound energy within the construction.

Ventilated facade systems can be easily designed to accommodate acoustic absorption, by simply including a mineral wool insulation slab within the build-up, typically with the light steel frame, enhancing not only the acoustic performance but thermal performance in a cost-efficient way.