Glass has made its way as a wonder material and deep inroads in the building industry. It has revamped itself hugely and the industry has broken the conventional fears and norms of breakage, safety, security and several other factors and addressed them head-on. The technological innovations in glass and glazing have helped and rewarded the industry with substantial growth in volumes and adding diversity and versatility in usage.

Façade glazing contributes to the aesthetics of a building and reduces the visual and physical weight of a building. It presents design opportunities to architects, where they can explore different geometric configurations and shapes of glass with customised module design and its assembly. Architects are still exploring its creative applications.

Window/Façade Glazing – Why is it Important?

The building façade refers to the outside or the external faces of a building, relating to the origins of the word meaning “facia” or “face”. Over time, the term façade has grown to also refer to the external layers of the complete building structure as well. Window glazing, or more commonly referred to as window glass, used in façade construction are a key element of the building envelope, says Dwayne Sloan, Director Principal Engineering, Built Environment, UL. Window glazing is an essential material used largely to encapsulate the perimeter of the building.

A window can also be called the eye of the building. Window or glazing refers to similar functions, but generally differentiated based on their scale or sizes, says Rajan Govind, Director, BES Consultants. The window serves several functions and protects occupants. Furthermore, the window gives characters and aesthetics to the building. Hence it is an important component of the building.

Nilesh Gandhi, Principal Architect, Meta Design too agrees that windows are super critically important as the eyes of the structure since they are the ones through which the building relates and interacts with the external environment. He adds: “direction, specifications, wall to window ratios popularly called WWR, define natural light, heat, ventilation, insulation that are lifelines for building efficiency”.

Ar. Gaurav Goel, Founder & Principal, Studio Parametric Curiosity adds that window/façade glazing provides a weather shield to the interiors of a built structure, also protection from the exterior environment elements like temperature, sound and wind control. Glazing is a part of a wall or window, made of glass.

Strong, durable and high quality glazing offers many benefits to commercial properties, points Ar. Prashant Deshmukh, Founder & Principal Architect, Prashant Deshmukh Associates “Homes window glazing is more energy-efficient, saving you money on heating bills. Good quality windows will also make it easier to regulate the overall temperature of your building,” he adds.

According to Jatin Shah, Managing Director, Technical Due Diligence (India) at Colliers, Glass the primary element, is selected based on various functional and aesthetic criteria to meet the overall engineering requirements of a project. “Right from the project concept stage, a suitable methodology should be laid down by stakeholders to understand implication and influence of available façade options.

Effect of window type/glazing system design is not only driven based on codal requirements or cost of the system, but also includes investigation based on parameters like safety, lighting, acoustic, thermal, fire, durability, life cycle, maintenance and buildability with the right detailing,” adds Shah.

The glazing and its framing must be functional and possess performance attributes including, but not limited to visibility, aesthetics, physical security, thermal, structural, UV protection, fire protection, ease of installation, resistance to air infiltration and resistance to water penetration, adds Sloan.

The Importance Of Using The Right Kind Of Glass

Right glass helps to achieve a superior indoor environment and reduced HVAC loads, observes Rajiv Balaggan, Sales Head – Architectural Glass India, Pilkington Glass India Pvt. Ltd.

He lists a few important factors that need to be kept in mind while selecting the right/perfect glass:

- Geographical location & type of structure

- Correct glass/glass combination unit

- Interior & exterior appearance

- Energy efficiency

- Acoustic property

Façades and windows play a great responsibility to be efficient by choosing the right kind of glass. First get the basics right that the building is designed for the climate and context, advises Ar. Balaji Gunasekaran, Associate Director, Katerra Design. Next, the building is oriented well to achieve the passive design. Glass must be sensibly chosen on following major factors to achieve maximising daylight, negating solar ingress, minimising glare, enabling ventilation, points out Balaji.

Solus Office at Bengaluru

Sharing the example project – Solus Office at Bengaluru, a mid-range commercial office project of about 60,000 Sq ft and located off JC road, Ar. Balaji Gunasekaran, Associate Director, Katerra Design says that this project was challenged initially to go for single glazed units as a cost factor.

Then the clients were explained about the importance of energy savings by using double glazed units – reduction of OPEX cost with all design excel sheets supporting the data.

“Since the client was practical, and we did a mock-up for smaller furnished office space with different glass units of SGU & DGU to analyse the virtual benefits. Thus the client understood the importance of energy savings with the live reading and energy savings and finally gone with Low E glazing in façades”, explains Balaji on selecting the right façade.

Safety Glass – Tempered / Wired / Laminated

There have been numerous innovations since glass was understood as a building material. Current innovations have improved the security performance of brittle glass as a material. Based on different chemical treatments and manufacturing processes, different security glasses are available, says Ar. Goel.

Safety glass is considered to provide safety in the event of breakages, and less prone to inflicting injury when it breaks, notes Govind and Gunasekaran. It also includes glass that is manufactured for more strength and fire resistance. Safety glasses are mainly used with two layers of glasses sandwiched with an interlayer. In some cases, monolithic tempered glasses (thicker glass panes) shall be used for safety, however monolithic tempered do not provide adequate safety as compared with laminated glass units, hence they should be used with care, adds Govind.

Tempered glass (also known as toughened glass) is made by heating annealed glass uniformly and then cooled rapidly by blowing air uniformly onto both surfaces at the same time by a process known as air quenching. This process alters its brittle breakage pattern. These glasses, when broken fall into smaller pieces rather than big pieces as in the basic float glass which is dangerous to the building user.

Tempered glass is about four times stronger than a lite of annealed glass. Tempered glass can resist the forces caused by heat, wind and impact. While breaking, it shatters into small cubes, reducing the likelihood of serious injury on impact. Therefore, it qualifies as a safety glazing material. The tempered glass helps reduce the possibility of thermal/mechanical breakage. It has been mandated to use tempered glass worldwide. Tempered glass is pre-stressing glazing to ensure that the glass has certain physical properties by prestressing the glass, says Matt Schumann, Industry Manager, Building Materials, UL.

Wired glass is made by feeding a welded wire net into the molten glass just before it enters the rollers. The wire does not add to the strength of the glass, but it does hold the lite (a cut piece of glass) in the window sash if it shatters. Wire glass is used in fire-rated windows and doors because it meets most fire codes. However, wired glass use is limited in many places as it does not meet impact safety standards, adds Schumann. Wired glasses are used in the olden days, currently, it is not common, says Govind.

Laminated glass is a glazing fabricated from multiple layers bonded together with an adhesive to create a single panel. Lamination is used to create glazing with higher security against forced entry and to provide bullet resistance, says Schumann.

Laminated glass is used in safety glazing applications. However, it has many other applications, such as burglar resistance, sound reduction, sloped glazing, skylights, and space enclosures. Laminated glass can be used to reduce the transmission of solar energy, control glare, and screen out ultraviolet radiation. Laminated glass is made by placing a layer of Polyvinyl Butyral (PVB) between two or more glass lites. The PVB can be clear or tinted.

The laminating process can be performed on clear, tinted, reflective, heat-strengthened, or tempered glass. If the laminated glass breaks, fragments will remain stuck to the interlayer, typically of PVBl, ethylenevinyl acetate, or thermoplastic polyurethane, between its two or more layers of glass, eliminating the risk of injury, adds Balagan and Deshmukh.

Because of its unique safety feature, it is being used more in architectural applications now. Safety conditions under which a glass behaves when subjected to various impacts determine the type of glass to be used, says Shah. The glazing material is treated or is combined/fused with other materials to meet such performance criteria.

National Building Code 2016 defines various parameters are critical locations at which a toughened or tempered safety glass and locations under which a laminated glass should be used. The thickness of such usage depends on span, loading conditions and various other factors.

Primarily as defined in NBC 2016, it is recommended to use laminated glass for all horizontal or sloped glazing, for glass railings and where the sills are less than 750mm and fall height is greater than 1500mm. For fall height less than 1500mm and sills less than 750mm, tempered or toughened glass should be used, advises Shah.

Uses of Tempered, Wired and Laminated Glass:

• Tempered Glass is used in buildings for unframed assemblies (such as frameless glass doors), structurally loaded applications, and any other application that would become dangerous in the event of human impact. Building codes in the United States require tempered glass in several situations, including skylights, glass installed near doorways and stairways, large windows, windows which extend close to floor level, sliding doors, elevators, fire department access panels, and glass installed near swimming pools.

• Wired Glass is exclusively used on service elevators to prevent fire ingress to the shaft, and also why it is commonly found in institutional settings which are often well-protected and partitioned against fire.

• Laminated Glass, remains intact when broken, it is also great for overhead glazing in buildings. Due to their noise insulation properties, laminated glass can also be used at hotels, airport terminals, recording studios, etc. You can use it either in windows, roof lights, canopies; overhead glazing, domes, skylights, and glass lift walls.

(Ar. Prashant Deshmukh, Founder & Principal Architect, Prashant Deshmukh Associates)

Climatic Suitability and Eco-friendliness Of Glass

Out of several materials used for façades, glass is being one of the widely preferred. Glass manufacturing technologies are evolving quickly, and innovative products achieve high performance and energy efficiency. Furthermore, it offers comforts like natural lights, and protections against extreme weather.

Building façades of ecofriendly buildings are achieving much higher performance through modern materials and construction techniques, thus able to contribute sustainably and achieve the highest level of green building ratings, says Govind.

Glass is made of abundant natural raw materials like sand, soda ash, cullet (broken glass), etc., and it is a fully recyclable material. Glass recycling helps in saving energy as cullet melts at a lower temperature than other raw materials, says Balaggan. Glass also used to generate renewable energy. According to Ar. Gandhi, glass has higher performance, speed of execution, but it comes at a cost of higher embodied energy. Hence a justified analysis and exploration and due diligence are required while opting for glass on façades and fenestrations. DGU glasses that provide insulation reduce the overall HVAC loads and requirements.

Glasses manufactured with higher SHGC, help in the reflection and non-absorption of heat conductive to the envelope. If the glass is used in locations where it is not required as a functional element, it will add to the absorption and heat gain of the interiors. One of the vital environmental factors is the thermal performance of glass. This can be enhanced by layering glass into different arrangements in its assembly or by coating it with materials to reduce its ability to transfer heat indoors., says Ar. Goel.

Shah points out the need for the careful and planned use of glass by control of solar gain and UV while maintaining performance parameters. It helps to reduce dependency on artificial light. Further, when glass breaks, it remains safe and stable and releases no harmful chemicals into the soil. So even if the glass is not recycled, it does minimal harm to the environment. Additionally, glass has the GRAS designation (Generally Regarded As Safe) from US Food & Drug Administration, adds Shah.

Ar. Gunasekaran too agrees that glass is sustainable since it is a fully recyclable material that provides great environmental benefits such as contributing to mitigating climate change and saving precious natural resources. Other than saving energy, glass is also used to generate renewable energy through solar-thermal and photovoltaic applications and wind turbines, which largely profit from lightweight reinforcement glass fibers, he adds.

Glass provides natural light into buildings which enhances the living and working conditions of the occupants. Studies show that glass in buildings, through all these benefits, contributes to people’s well-being and improved health conditions.

Selecting the Right Glass for Façade and Fenestration

Characters of glass-like transparency, masking, the ability to fabricate, adaptability, etc. highlight its suitability for structures. It is sound insulating, heat-reflecting, heat absorbent, nonabrasive, weather-resistant and incombustible. By understanding the building requirement, optimum basic glass is selected. With the logical and correct selection, it can be very useful and friendly material.

An incorrect selection can result in just the opposite by being a source of excessive heat gain or loss, glare, discomfort and risk of injury from glass. The primary function of glass is to provide daylight and visibility through it or transparency.

Visible Light Transmission or VLT is the most important parameter of glass and higher VLT will result in higher daylight but also higher energy transfers and glare. The designers often consider that a higher VLT means higher transparency and end up with the wrong selection.

Transparency is dependent on the colour rendering index, reflectivity and illumination levels inside v/s outside. A glass of VLT as low as 10% is also quite transparent if viewed independently and not in contrast or simultaneous comparison with a higher VLT glass. Other than light and energy, the factors like strength, safety, acoustics, etc., should be considered to evaluate the processing needs of glass. It will be useful to bring a method to the selection process which is easily understood by all the stakeholders and steers them to a common approach.

The National Building Codes 2016 has introduced a new section 8 of ‘Glass and Glazing’ under Part- 6 ‘Structural Design’. The code covers almost all design aspects of glass and glazing. It explains various types of glasses as well as processes and defines the methodology of selection as well as drawing the boundaries of certain limitations. Right from the initial project evaluation stage, a suitable methodology that incorporates the implications of the use of glass materials and their influence on the performance of the building shall have to be looked into.

Design requirements, including aesthetic considerations and client-specified requirements such as security and maintenance, are to be considered. Effect of design on cost such as the initial cost of glazing (specification of glass; glazing method; access for initial glazing; work schedule; protection during construction); effect of glass material on capital; running cost related to building heating/cooling, lighting and ventilation; and maintenance cost of glazed areas (access for cleaning and re-glazing) should be considered as well.

(Ar. Prashant Deshmukh, Founder & Principal Architect, Prashant Deshmukh Associates)

Types of Glazing

Types of glazing are generally called based on their visual and construction methods, explains Govind.

Visual-based Category:

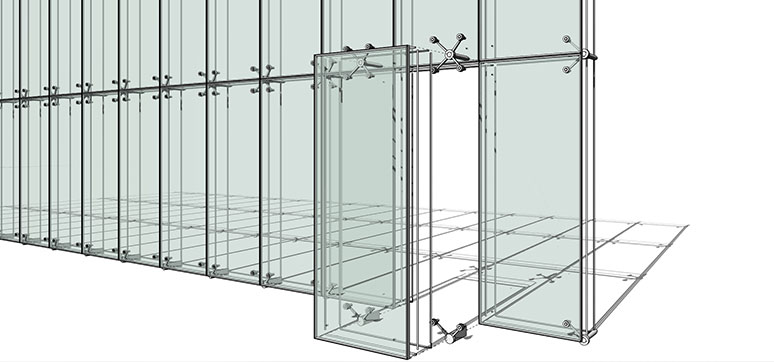

- Structural glazing caters to more transparency with lesser frames or obstructions called frameless or bolted or spider glazing.

- Cable or suspended glazing refers to a supporting structure that uses a tension cable system against structural frames.

- Curtain walling refers to framed constructions such as windows, commercial building façades, etc.

Structural glazing:

According to Balaggan, structural glazing is a more specialised job of fixing perfectly uniform large glazed surfaces with silicone. In this system, glass is fixed to support which is attached to a structural element of the building. This system can be used with any type of glass, even DGU. Structural glazing can be used to create huge glass installations with minimal obstruction, says Ar. Deshmukh. Structural glazing refers to a method of retaining the glass in a window, storefront or curtain wall, points out Gunasekaran.

Instead of the edges of the glazing being captured in a pocket of the framing and secured in place with gaskets, the structurally glazed glass is retained on one or more sides by an adhesive, normally silicone. Structural glazing is one of the fastest-growing and most innovative forms of glazing.

Spider glazing or bolted glazing and fin supported glazing are types of structural glazing.

-

Enjoying the view from a glass façade building – UL Lab Frameless or bolted or spider glazing: According to Ar. Deshmukh, spider glazing acts as a structural support for any high-end exterior designs. Structural support for the spider glazing can be taken from the structure of the building and for the larger elevations. Spider glazing is generally installed in areas where maximum visibility is required. Glazing with steel tubes as a vertical backup supporting structure called bolt glazing /spider glazing.

Explaining it further, Balaggan adds that in the bolt/spider glazing system, the glass is fixed at points with specially designed bolts and steel plates rather than a frame. This is the less obtrusive alternative of glued-on structural glazing. Spider glazings are the most transparent structurally glazed systems used, agrees Gunasekaran.

Silicone sealants between the joints are like other structurally glazed systems, but have far less obstructed views looking from the inside out and vice versa due to the elimination of vertical and/or horizontal aluminium mullions. This system is often used for the main entrance elevation of big structure, double lobby, atrium, skylights, canopies and elevator enclosures.

-

Spider glazing source eurosystems com – Parametric Curiosity Fin supported glazing system: Glazing with laminated glass fins as a vertical backup supporting structure called fin supported glazing. This system, says Balaggan, offers unique and transparent façades especially if the low iron glass is used. Glass fins can be suspended from above or rested on the structure below. Maximum heights can be achieved with this system.

Spider and Pin fittings are usually bolted on the side of the fins and steel shoes and connector plates keep the fins in place. This type of glazing is considered good for projects with height and required less obstructive view. Fin systems are also designed with bolted joints. Fins represent the earliest form of structural glass façade.

Cable & Suspended Glazing System

Glazing with stainless steel tension rods as a vertical backup supporting structure called cable glazing/ suspended glazing. It could be considered a type of structural glazing.

- Cable glazing system can use both vertical and horizontal cables from the boundary structure to act as a support for bolted glass panels. These high tensile cables or stainless steel rods to impose loads of the façade on the main structure. A surrounding frame is built with cables brought across it and those cables are pulled tight and locked in a place, explains Balaggan and Ar. Deshmukh. This is mainly used for huge entrances, skylights, etc. This decreases the amount of solid structural elements visible on the project.

- Suspended glazing system is used for very high glass panes to avoid flexing and buckling due to self-weight. It absorbs the movement of the building. Single glass panes are suspended using tongs, which press on both sides of the glass.

Testing and certification by UL

UL 752 is a test Standard for Bullet-Resisting Equipment and is used to evaluate resistance to different levels of ballistic attacks. The term “bulletresisting” signifies that protection is provided against complete penetration, the passage of fragments of projectiles, or spalling (fragmentation) of the protective material to the degree that injury would not be caused to a person standing directly behind the bullet-resisting barrier.

These applications are intended to protect against robbery, holdup, or ballistic/armed attacks such as those by snipers. UL 972, is the Standard for safe, burglary resistant glazing material. These products are clear, translucent, or opaque glazing material intended for indoor and outdoor use principally as a substitute for plate glass show windows or showcase panels. The material is intended to resist burglary attacks of the “hit and run” type.

Curtain Wall System

The curtain wall system is an outer covering of a building and generally not resting on the concrete structure and just connected to it, adds Balaggan. Curtain walls are not structural and they are only able to carry their own weight, observes Ar. Deshmukh. They are thin and lightweight, and an affordable option for a building’s exterior casing, he adds.

According to Gunasekaran, curtain walling is a vertical building enclosure that supports no load other than its weight and the environmental forces which act upon it. A curtain wall is defined as a thin, usually aluminium framed walls, containing infills of glass, metal panels, or thin stone.

Double-Glazed / Triple Glazed Windows

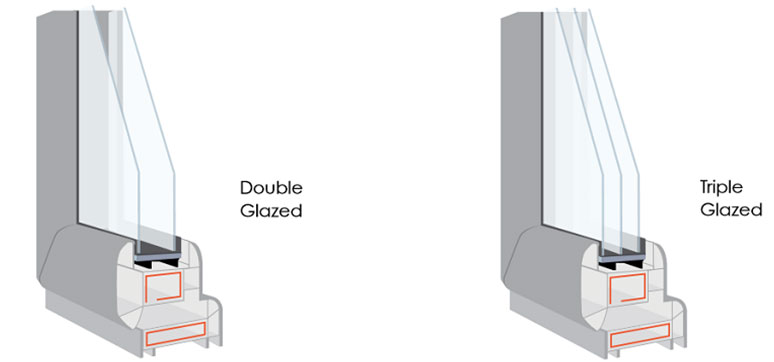

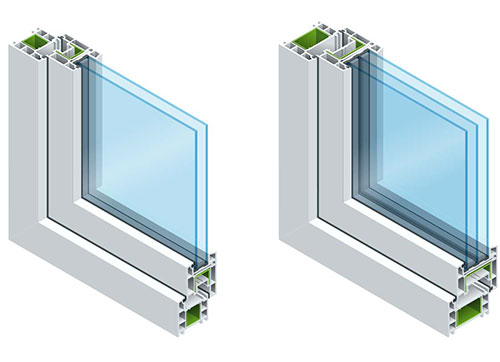

Glazing for fenestration products was originally built with a single pane of glass installed into the products for many years, says Dave Stammen, Principal Engineer, Building Envelope, UL. Through research and improved manufacturing processes, the use of double-pane and even triple panes of glass in an insulated glass unit (IGU) were developed and installed in window systems, which allowed for providing an air space between the panes of glass, thereby greatly improving the thermal performance such as heat loss reductions, when filling the space with inert gases such as argon or krypton.

New developments in the use of vacuum glazing, which creates a vacuum in the air space between the panes of glass, now allow greater improvements in thermal performance when compared to the original standard double-glazed products. Also, using double or triple glazed IGU’s will provide improvements with the overall acoustics or noise reduction of the finished fenestration product, adds Stammen.

Glazing panel formed by assembly of two panes of glass sandwiched with airspace to create IGUs called double-glazed (DGW) of insulated – or three panes are used for insulated called triple glazed (TGW) glass panes separated by a gap and filled by either vacuum or inert gas and the entire system is completely sealed to prevent escape or entry, improve thermal insulation and acoustics. Thermally insulated windows keep the air in a room warm and obstructing cool air from entering and are commonly used in extremely cold climates.

Since a room loses a significant amount of heat through its windows, glazing can play an important role in keeping your home and office spaces warm. NBC 2016 has covered the design aspects and selection criteria on the type of glass (internal and external) based on evaluation parameters like reflectance, solar energy transmittance, UV transmittance and U-Value and at the same time have defined criteria on thickness, size of the glass panel and various related compliances like structural silicone, etc. TGW is fitted into a uPVC or aluminium frame to offer improved insulation and ease of installation.

To decide which configuration is best suited for your space, take your location into account. While triple-glazed windows are ideal for cold environments that barely get sunlight, they are priced higher.

Both configurations, however, offer undeniable benefits (in terms of money and comfort) to your spaces, says Ar. Deshmukh. Energy saving in TGW is approximately (40-50%) more than in DGW, points out Balaggan. Ar. Goel, agrees that the insulating properties of triple glazed windows are about 20 to 30 % better than double glazed windows. Both types of glasses help in reducing energy loads of heating and cooling and hence they are used to achieve energy saving targets in eco-friendly architecture.

According to Schumann, the benefits of using double glazed or triple glazed windows is that each additional piece of glass and air pocket increases the insulation value of the glazing while also reducing the sound transmission through the window. The multiple panels also allow for glazing to be tailored to the installation by providing surfaces to add films/coatings to reduce heat gain, provide colouring or tint, in addition to adding ballistic or security attributes. The result is a marked improvement in energy efficiency and sound transmission over a single pane of glass.

Advantages of Double & Triple Glazed Windows

Double glazed windows offers:

- Noise reduction – Double-glazed windows cancel noise from the outside, thus soundproofing a room

- Reduced electricity bills – Double-glazed windows help in lowering energy costs. Their superior insulation properties keep spaces cool during the summer and warm in the winter, thus reducing energy bills

- No condensation – These windows are designed to be watertight, preventing water droplets from freezing on the surface and turning spaces cold in the winter

Triple glazed windows offers:

- Superior insulation – Compared to double-glazed windows, triple-glazed windows offer substantially better insulation properties

- Enhanced noise reduction – With their superior noise reduction properties, triple-glazed windows are particularly advantageous for those living in a noisy area

(Balaji Gunasekaran, Associate Director, Katerra Design)

Types of Façade Glazing

Façade glazing can be categorised into many types based on their assembly and construction tectonics.

Structural Glazing: Structural glazings are glass assemblies that are attached to the structural system of a building like its slabs and columns using adhesives like silicone. These systems give a flushed appearance on elevation with the impression of continuity without frames. Generally, a big glass elevation with neat adhesive joints is visible in such systems. These form a large part of institutional and commercial architecture.

Spider Glazing: This is a type of flushed glazing that is devoid of frames. Glasses in this glazing system are held together with building structure along with 2- or 4-way spider SS bolts. Eventually, the joints between glass modules are filled with silicone sealants or gaskets in such systems. Suspended glazings are used in large retail and commercial façades where a larger footfall of people is expected along with high safety standards.

Fin Supported Glazing: This assembly comprises vertical tempered glass fins for support along with horizontal glass modules fixed to these fins using specific bolt connections. This glazing can be useful for Stone fronts, taller elevations, or areas where the external wind pressure is of vital concern.

Cable Glazing: These are glazings that use tension cables or rods to transfer façade and external loads to the structure of the building. Due to these tension cables, the frame area decreases and the façade become lighter and more transparent. These glazings can withstand higher wind loads without a big frame structure. They can be used in larger retail and commercial areas.

Curtain Wall: These are glass assemblies that span like a curtain between floor slabs of a building. Their assembly consists of frames in which glass modules are assembled to construct a full glass wall. These systems are non-load-bearing and have to support their own weight along with the external wind pressures.

(Ar. Gaurav Goel, Studio Parametric Curiosity)

Enhancing Thermal Performance of Glazing

By using correct glazing products such as high-performance materials, we can achieve the highest level of energy efficiencies such as LowE or solar control coated glass products, insulated glasses, etc., says Govind. Balaggan adds that the thermal performance of glass can be enhanced by using – a double glazed or triple glazed unit; Low E coated (low emissivity) glazing unit; spectrally selective glazing; and vacuum glazing unit.

Innovative glazing systems:

Innovative glazing systems are developed for energy efficiency in buildings – either to reduce window heat loss in winter or solar heat gain in summer. In highly insulated assemblies, the constraints placed are due to:

- edge-, frame- and spacer induced heat losses, and

- External and internal surface resistances are caused by the range of flow regimes found in the built environment.

A thermal resistance network model is used to determine the so-called ‘night-time’ U-values of different assemblies that are typically measured by hotbox techniques, explains Ar. Deshmukh. It treats the problem as one involving complex conjugate heat-transfer mechanisms with unknown interfacial temperatures at the glass boundaries of multiple (single, double and triple) glazed units.

The ‘advanced’ glazing systems that have cavities containing low conductivity gases, together with low emissivity coatings on the boundary glass surfaces improves thermal performance. Evacuation of the cavities is examined as the ideal or limiting case. Adopting new designs featuring triple glazed systems and the use of low emissivity coatings caters for better thermal performance, says Ar. Deshmukh.

Stammen from UL too finds double or triple glazed products as solutions, as well as using thicker individual panes of glass within the IGU. The use of non-metal spacers, films and coatings on glass panes such as low-emissivity (Low-E), as well as the use of inert gases such as argon or krypton within the IGU air space, are ways to provide overall thermal performance improvements.

Newer developments are also being researched, such as the use of vacuum glazing which creates a vacuum within the airspace of the IGU, as well as the use of phase change materials within the air space that is designed to store heat as the material changes phase, then releases the heat when changing back to the original state. Gandhi and Shah, too suggest the use of double glazing units, glasses with a lower VLT, having higher reflective properties, improves the thermal performance. Auto Switch glasses, tinted, shaded, glasses or opaque glasses will reduce the heat gain and improve thermal performance.

According to Shah, a lower U value means better performance in terms of insulation to heat conductivity. Additionally, a solar film, Low E coated glass, thermally breaking spacers, frame construction with a low-thermal conductive material, recess of glass, installing glass at an angle based on sun-path analysis are some of the measures which can be implemented. Gunasekaran observes that achieving optimal thermal comfort is still a challenge. Primarily because the main deterrent is the rapidly changing climate which makes it necessary to continue research and evolve design & construction techniques to achieve this.

Glass or glazing is a fenestration element often used to scale down the quantity of energy or heat gain transmitted through it, especially in cases where external shading devices are inappropriate to the design vocabulary or rescind views & vistas that should have been preserved. “In such cases, we can use toned glass, low emittance glass, or double-paned glass. Alternately, we can also use reflective coatings which ought to be affixed professionally though,” says Gunasekaran.

Toned glass incorporates a tint applied to the glass to scale back the quantity of warmth transmitted through it. They tend to stop greater amounts of heat gain. Low E glass is essentially a standard clear glass with a microscopic, transparent coating on its surface that is better at reflecting heat than the glass itself, creating a composition that has a lower emissivity than standard glass. Combining low E with multiple panes of glass increases energy efficiency even more.

While these are the standard methods, there is a serious breakthrough in glazing technology that can take energy performance to a different level. These include electrochromic glass, Alumino-silicate glass, building-integrated Photo Voltaic and Phase changing materials.

Managing Glare Using The Right Design & Glass

Glare, also known as visual discomfort can be defined as “too much of light”, points out Balaggan. By going with the right design and choosing the right glass, we can manage glare to a large extent. Glass has several characters of the light spectrum. The selection of glass must be a balanced approach optimised for various aspects between transparency, performances, and visuals, says Govind. Hence the glass selection is based on a balanced.

Talking about ways to reduce glare, Balaggan suggests avoiding direct solar radiation, the use of a shading device helps us reduce the glare. For glazing, glass with low light transmission (depending on the type of project and its orientation) can help reduce glare. The use of anti-reflective glass maximises visibility and minimising the light reflection and glare. It can also be managed by using glare reduction films, he adds.

Ar. Deshmukh talks about the emergence of dynamic technologies such as smart glass whose capacity levels can be controlled with the switch of a button. Glass takes less than 10 microseconds to activate, block up to 50% of light in its off mode. It works between temperatures from 00C degree to 550C. It can last for a minimum of 20,000 cycles and is available in a variety of colour tints.

Following are some points to manage glare through design:

- Provide as much natural light as possible

- Reduce the potential for direct and reflected glare wherever possible by specifying flat floor and wall finishes rather than glass.

- Avoid shiny metals and metallic paints

- Use indirect lighting wherever possible to produce high levels of ambient light.

- Avoid fixtures with bare or exposed light bulbs.

According to Shah, even after reducing light transmittance perceptibly, glare reduction might remain a challenge. “Often, we will need more than one method to control glare. The combination of the right selection of glass, sun-control films to block UV rays, awnings or shading devices, draperies can help control glare. Glare can also be controlled by smartly positioning windows based on sun-path analysis’” says Shah. With automation and electrochromic glass, glare control may not require any external shading device or films or draperies to provide comfort to users.

Five Ways to Manage Glare

- Apply window film: cover south- and west-facing windows with temporary heat-control window film to block direct glare from the sun (specially designed to block ultraviolet rays).

- Awnings and shutters: Install a roof overhang such as an awning on the exterior of your window to permanently block direct sunlight. Install exterior or interior shutters that you can open and close as needed.

- Draperies and shades: Rolling solar shades give you a bit more versatility than awnings or window films because you can open or close them as needed and choose colours that match your decor. Pull the shades down from early morning to afternoon to block the harshest of the sun’s glare, while still allowing natural light into your home. Another option is to use, either in conjunction with shades or on its own, is hanging thermal curtains instead of sheers or thin fabric draperies. Thermal curtains have a heavy blocking material that blocks sunlight during the summer and helps regulate the temperature inside of your home.

- Landscaping: Trees can also provide excellent glare-blocking and shade during the winter months. Plant a tree on the western side of your home in a location that shades west-facing windows from the afternoon sun during the winter months.

- Decor colour: Paint your walls a brighter color to make the window seem less bright in comparison to the room’s surfaces. Glare also comes from the sun’s reflection, so when the scenery outside is bright, and your interior is dark, the window seems brighter as a result. By painting your walls lighter, you can reduce this effect because you make the room as bright as the window. This is ideal when you have only one window in space as a source of natural light and covering it would reduce light significantly.

(Balaji Gunasekaran, Associate Director, Katerra Design)

Tackling Noise

Like any other building products, the acoustic performance of glasses can be enhanced with the use of laminated or insulated or insulated laminated glass products, says Govind. Glass products are available from the acoustic/noise insulation range from 30 to 50 dBA, to manage high noise pollution which may come from traffic, public spaces, etc. Balaggan says that we can control it by keeping its level within acceptable limits.

Following glazing options can be considered for controlling sound insulation:

- Using thicker glasses

- Using double glazed unit (sound insulation improves by using different thickness glass)

- Using laminated glass unit (preferably with acoustic interlayer)

- Using the combination of the insulated and laminated glass unit

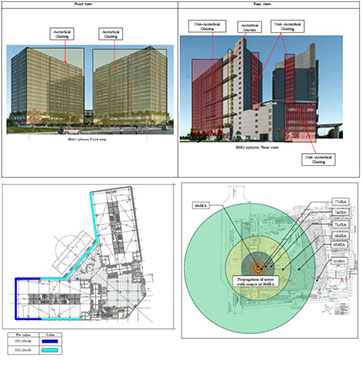

Ar. Deshmukh advises choosing the thickness of glass to be used for a building façade based on the noise pollution level in the surrounding. Higher air gaps between the IGUs have a very significant impact on sound reduction. Usage of laminated glass and sing different configurations of glass can reduce noise pollution up to 55-60 dB. Asymmetrical double glazing is another option. Due to resonance, it is better to use glasses of different thicknesses inside the IGUs. They will resonate at different frequencies, thereby giving slightly better sound protection, adds Ar. Deshmukh.

Adding the air gap between glass panes is the aptest and the best option to add acoustics to the glass performance, points out Ar. Gandhi. A Typical 22-25mm DGU, with 5mm + 12mm air gap + 6 mm, will provide for a good 80% noise reduction. Paying close attention to detail in managing joints, and sealers, which are high probable noise leakage locations, are critical for overall acoustic performance, he adds.

Acoustics study involves understanding the source of production, transmission, control, and the effect it has on residents of glazed buildings, says Shah. Planners and stakeholders need to engage a specialist who can run field studies to advise DGU configuration and type of glass to reduce the dB level based on surroundings, height, type of landscape and usage. Acoustic insulation is an integral aspect of the ‘Well Being’ of an occupant.

DLF Cyberpark by BES Consultants Typically, a hermetically sealed DGU window will provide a reduction of 40-45 dB only. A laminated glass serves as a noise dampener is more effective in weakening the noise level. As such a study of parameters can help define the thickness of outer glass or the type of laminated glass and what thickness, vacuum gap in case of DGU, the thickness of inner glass to provide a comprehensive solution. Additionally, the type of structural frame or assembly and how the installation of the system also contributes to noise reduction points out Shah.

Laminated glazing or insulated glazing units will help limit the noise transmission when compared to a monolithic product, agrees Schumann. The air pocket or film layer limits the movement. Other elements include a review of the sound transmission ratings for the doors, windows, framing systems and the choice of finishes and materials inside the space.

Minimisation of Noise Transmission

Building acoustics is the science of controlling noise in buildings. This includes the minimisation of noise transmission from one space to another and the control of the characteristics of sound within the spaces themselves.

Unwanted sounds can create distractions, damage hearing, occupant productivity, wellbeing and even sound leakage that could affect privacy. The best way to manage acoustics efficiently is to address the issue at the design stage itself. Measure the site context and use of acoustic glass on façades shall resolve the noise issues 90%.

Bilva IT Park at Bengaluru by Katerra Design is designed with great care of acoustics since it is located at Whitefield-Hoskote main road which has busy traffic and near to Hope farm junction Metro station, which is 15 -20m away, the noise levels were measured on-site survey as 80dBA. The glass façades were designed with three different glass specifications based on the proximity to Metro station and road.

Laminated double glazed units (27.52mm) at glass façade close to road and Metro to reduce the noise levels by 40 dBA; double glazed units (26mm) at front elevation little away from the main road to reduce the noise levels by 35 dBA; and double glazed units (24mm) at rear side to reduce the noise levels by 30 dBA.

(Balaji Gunasekaran, Associate Director, Katerra Design)

Smart & Energy-Efficient Glass

In recent years, various smart glass technologies have been designed to automatically regulate light and heat based on environmental conditions. “Smart glass technology is still evolving; we can hope that this technology will reach the wider building community soon which will make smart glass products affordable. Energy-efficient glasses have become a standard, must have design solution, which we have been seeing in the majority of construction projects in recent years”, says Govind.

According to Balaggan, energy efficient glasses are affordable in the present market. Smart glasses are still beyond affordability for most of the projects. He hopes that with time, the difference will settle down and it will become an affordable product. Ar. Deshmukh agrees with this and adds that their high price tags have prevented them from achieving widespread application. He spoke about the MIT research which has discovered an alternative to smart glass that could come at an affordable price.

Research developed affordable smart glass alternative, by stretching a material to increase its transparency, also is switchable and having tunable optical properties which are worth pursuing concrete engineering applications such as indoor light control through smart windows. Smart glass-like electrochromic glass is expensive which can be tried out at a critical part of the façades. Gunasekaran, opines that quality things come with a price.

The manufacturer’s approach should educate clients on the merits of using smart glass and energy-efficient glass. Those glasses provide thermal comfort which is important for the health and wellbeing of occupants which increases productivity. It reduces air-conditioning load by 30% and thus overall energy savings by 11 to 15% which means a reduction in maintenance and operation cost. “In Bilva IT Park at Bengaluru, Electrochromic glass – SAGE Glass was tried in the west and south elevations for 30% of the façade. Considerable energy saving of 5% of Air conditioning load reduction and thus cost reduction,” he adds. Talking about the passive methods, measures like orientation, façades, fenestrations, etc. are not thought of in the concept phase, explains Ar. Gandhi.

Earlier passive planning will reduce the usage of expensive glasses and allow the function of normal affordable glasses. Shah notes that with the opening of large volume facilities, manufacturers are expected to achieve economies of sale, which will help lower the cost. In India, if the production units are shifted to the country with active policy changes under various GOI initiatives, the cost can be further brought down.

Apart, stakeholders while evaluating options should conduct a cost benefit analysis (as energy costs are increasing) holistically and not only look at immediate additional expenditure which might be 4-5 times higher than conventional.

Future of Glass and Glazing Industry

We are seeing new technology bringing a large number of high performance products, improved fabrications, efficient use of materials, modern construction techniques, etc. Advancement in materials has been seen in glass products, in particular pushing boundaries of technologies and innovations, says Govind. There is a lot to come up in the new decade in the glass and glazing industry, adds Balaggan. For the industry, the use of glass is increasing day by day and it will increase further with time. From the industry side, new innovative products will be launched. For example, currently, the world is going through a very tough time facing the Covid issue, and glass manufacturers have come up with a special product, Antimicrobial glass to help deal with this. The application of such glass is huge.’’

Gunasekaran talks about a few breakthroughs required in the field, including electrochromic glass is ‘smart glass with sensors’ installed under a low-voltage current that changes its tint and reflective properties depending on the external temperature. If the electro-chrome glass is installed, the energy use of the building is reduced up to 20%, and the peak demand is lowered up to 30%. Building-integrated photovoltaics (BIPV) are photovoltaic materials that are used to replace conventional building materials in parts of the building envelope such as the roof, skylights, or façades, he adds.

According to Schumann & Sloan from UL, considering all the functional requirements for glass noted above, the glazing industry is being challenged with increasing standards and regulatory requirements. With each new construction or performance regulation imposed, the industry must balance design and construction in a manner that all of the attributes can be satisfied appropriately.

Manufacturers will continue to develop new glass and glazing solutions that will be designed to satisfy multiple attributes in one product. It is expected that there will be an increased focus on products that offer a greater sense of security, larger openings to allow more light and visibility, potential fire resistance capabilities, and to perform better under severe weather conditions.

At the same time, more products featuring easier installation and potentially unitised construction will often be used to speed up construction and lessen the time it takes to complete the enclosure of the building. Over the next decade, it is expected that new and innovative window façade designs will be born out of the delicate balance of attributes needed to satisfy increasing standards and regulations.

There is still room for improvement in factors like capacity building, innovation, logistics and on-time deliveries. Integration and smooth, cohesive functioning with hardware, which is another critical component of the entire glazing industry, says Ar. Gandhi. According to him, hardware is the heart of any glass assembly and installation. All the various types of glazings derive their name from the type of installation, hardware and nature of use.

The glass and glazing industry have always come up with new, energy-saving, environment friendly products from time to time and the new decade will have a lot of options to choose from. At the same time, the use of glass and glass demand will keep on increasing with time.

What’s in Store

Electrochromatic glass or locally known term as smart glass which can alter the characteristics of a unit by an electric current that is also connected with daylight sensors is on verge of widespread adoption. Additionally, the integration of solar photovoltaic thin films on glass or façade is going to be a crucial step to harvest solar energy. With the adoption of large or jumbo glass panel industry will move closer to have larger windows as well as combining transparency, sustainability and codal requirements. With innovation in glass, shortly glass can also be self-luminous or can act as a connected device to BMS integrating cameras, sensors, and displays.

(Jatin Shah, Managing Director, Technical Due Diligence (India), Colliers)