Brief on Holistic Design approach for Fire- Safe Buildings, focusing on Façades and Fenestration Design?

The holistic design approach to fire safety starts by first understanding how fire behaves. Fire behaves differently with different types of combustion materials and fuels. Further, it will depend on the oxygen supply to that fire and the quantum of combustible material available to burn. One also needs to understand how fire spreads in a building before we start selecting the various elements of a façade. The most important aspect of controlling fire spread is breaking the continuity of combustible material in the line of fire range. The design of the façade must be such that materials have virtually no combustible component and if for unavoidable reasons they have to be used then breaking its continuity is a must to prevent fire from spreading to other parts of the fire-safe buildings.

Could you tell us About the Role of Design in Fire Safe Buildings?

The fire-safe building design involves every planned space. Every space will behave differently in a fire depending on its function, size and materials used. For example, a cafeteria with metal and stone furniture without a pantry and a high ceiling without a false ceiling is virtually a zero contributor to fire and can assist as a fire break in the continuity of fire in a building (provided the façade is also made of non-combustible material).

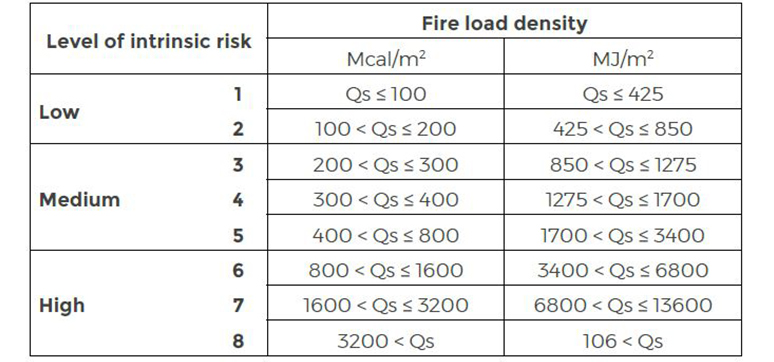

A storeroom, on the other hand, is a high-risk area and if it is located next to the façade, it will contribute to fire spread even if the façade is non-combustible due to high fire load. Building design must be able to calculate the fire load of every compartment during its expected operating life and the location of such compartments and façade treatment must follow as per these parameters.

What is the Role of the Fenestration Design in Fire-Safe Buildings?

Fenestrations have a very important role in designing a fire-safe building. During a fire, fenestrations act as a means of smoke release, as a rescue opening, but also as a means of fire spread to other compartments depending on design. When the smoke release is concerned, the windows must be able to open easily if there is suffocating smoke. Often the opening hardware is found to be too clumsy and windows fail to open during emergencies. The choice of hardware seldom gets attention with the emergency in mind.

uPVC windows perform poorly in the event of a fire and in fact, act as fuel to propagate fire. uPVC windows need to be judiciously used especially for windows or areas having near-zero fire loads. uPVC has a very low melting point and has had catastrophic consequences during the fire as seen in the case of Grenfell Tower and Lakanal House fire London.

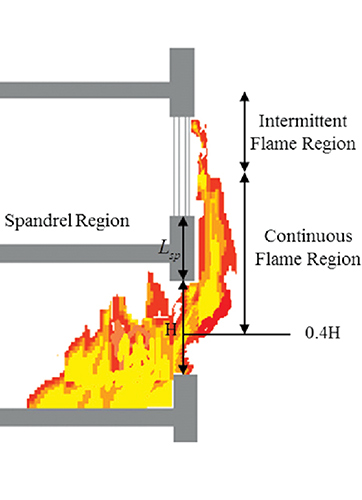

Windows need to be large enough and open wide to allow the rescue of people. Side openable or sliding windows are ideal for the rescue of people, however, other types like top-hung or parallel openings can be a deterrent. When the size of the fenestration is too big and without any RCC ledge for a vertical break, the fenestration will act almost like a façade and may assist jumping of fire from one compartment to another if there is no adequate fireproof separation.

Please Explain the Role of Structural Wall Elements and External Wall Composition (combustible elements in building façades), including Insulation and weatherproofing Materials, and other Products like Sealants, in Fire-Safe Buildings.

When we talk of external walls, whether structural or nonstructural, as per NBC and most codes, it is required to be as per NBC between 1 to 4 hours fire-rated depending on the type of building and distance from adjacent buildings. When we replace the external wall with a façade, then the same performance of fire rating is expected. The fire rating applies to every element of the external façade including sealants, gaskets, insulation, weatherproofing materials, façade structure, etc.

However, in reality, there is hardly any existing building that has a façade that comes close to even a 1-hour fire rating of a structural or masonry wall while 2 and 4 hours it totally out of bounds. Most insulation and sealant materials are petrochemical-based except Rockwool, fireproof boards and certain specialized fire-rated sealing products. However, there is a lack of strict regulation to ensure that non-fire-rated material does not find their way into the construction of buildings.

Only a fireproof façade, which is extremely expensive, addresses the fire rating criteria of exterior walls as per codes as every element, including glass, gaskets, insulation, etc., is fire-rated and tested for specific applications. Future designs will have to address this lacuna sooner or later as fires in glass façade buildings have proven to be more severe as compared to masonry external walls.

What are Passive and Active Fire Safety Protection Methods?

Passive fire safety is to do with the way a building is designed which will prevent fire spread and progress. A fire-rated barrier is a passive fire safety element. Similarly, a fireproof façade is passive fire safety. Any material that will not assist fire spread and prevent fire spread to other compartments or will assist smoke evacuation is considered as passive fire safety design elements – for example, masonry walls, structural floors, fire doors, dampers, smoke vents, etc.

On the other hand, all fire extinguishing mechanisms are considered active fire safety elements – like sprinklers, wet risers, hose pipes, fire extinguishers, etc., which will douse the fire either automatically or manually. When it comes to façades and fenestrations, they fall in the passive fire safety zone if the material chosen is such that it does not assist fire by contributing to fire load, or disintegrates and allows fire spread.

Please tell us about the Parameters Defining the Performance of Fire-Safe Façade Materials.

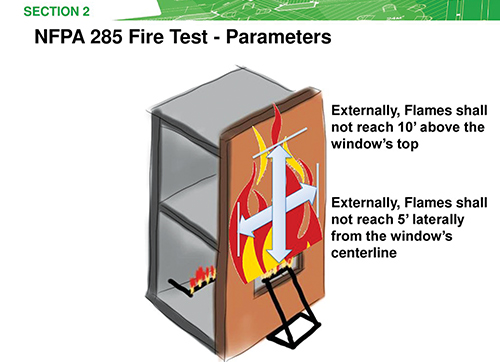

The façade must have some defined fire rating. If it has say 1-hour fire rating, then it means every element of the façade will maintain its integrity and not allow the fire to spread for at least one hour, nor it will support flame and smoke spread beyond defined parameters. The correct way to ascertain the fire rating of a façade and its material is to first test each element and material as per recommended fire tests.

The next step is to test the assembly of all these elements and materials as per NFPA 285 testing method which is an internationally accepted testing process for all external façade assemblies. If the desired testing is for 1 hour of fire resistance, then the entire assembly, including the materials, must pass the NFPA 285 test as per the test criteria to be qualified for a fire-resistant façade.

Please Elaborate on the need for Product and system Testing and Certification for Fire Safety. What are the Methods followed for the same? Explain the Large Scale Test Methods followed.

Continuing from above, each façade material is an important element of the façade assembly. If say aluminium clamps or brackets are used to hold the façade, and it comes in contact with fire, then it will melt at 660°C in a few minutes. Having a fireproof façade with such elements will be of no use if not adequately protected. This applies to every element of the façade assembly that holds its integrity to resist and maintain its shape and dimensions during the fire.

If the material is such that it acts as an insulator, but never comes in contact with fire, then that material needs to be tested for heat spread. An assembly is made of various materials those that face the first impact of fire, those that hold the material together and need to perform under extreme heat even though the flames may directly not touch it, and the third is insulation materials which may prevent heat conduction from one compartment to another or between two different fire rated elements.

Tests for every element as per function will be different under the relevant codes. A material is chosen based on the final performance of the assembly. Once the elements are identified correctly, the entire assembly is tested as per NFPA 285 as mentioned above. (Explaining NFPA 285 is very elaborate and will fall out of the scope of this article and I suggest readers speak to agencies who conduct such tests or speak to an expert for more accurate information.)

What Scenarios could cause an Internal Building Fire to spread to the External Façade and other parts of the Building? What Protection Measures Are in Place to Control Fire?

An internal fire can easily spread to a façade if the façade or fenestration is made of combustible materials. Materials like an aluminium composite with PE or LDP core are highly flammable. Wooden windows assist fire similar to ACP. Similarly, there are many façade elements that are poor in fire prevention and will either assist fire or disintegrate allowing the fire to spread to other compartments like the aluminium used in the façade, which will melt at 660°C.

Any material that is structurally held by the aluminium will eventually fall even if it’s a fire-rated material. When it is known that a façade is not fire-rated, then the planning should be such that the fire load of the compartment is not near the façade or fenestration. Heavy wooden furniture, upholstery and storage of flammable materials near the façade and fenestration will spread the fire to the façade faster. The way to ensure that the fire does not spread from one compartment to another is by maintaining adequate fire separation.

A fire separation is achieved with an adequate fire-resistant element like RCC or masonry wall or steel barrier around the effective fire chamber of adequate dimensions that will prevent the fire from jumping that distance from the fire compartment to the non-fire compartment. Depending on the type of fire load, the periphery of fire protection must be designed. It is a complex design process and cannot be generalized and needs to be addressed on a case-to-case basis during the initial architectural design process by a fire safety expert or a façade expert consultant.

Please explain some Common causes for Building Fires in India (due to bad building designs and negligence by the designers and engineers) and a few Remedial Methods for the same.

There are many reasons for the poor design of buildings in India when it comes to fire safety. The primary reason is compromising with building code practice which is either out of ignorance or deliberate to save costs or achieve aesthetics of fire-safe buildings at the cost of safety.

Let me give a few examples below to illustrate the shortcomings of designers, especially in India.

a) All compartments of a building must be designed to contain a fire for at least 1 hour to 4 hours as the case may be and not allow the fire to spread to another compartment. 2 hours are considered enough in most common cases to extinguish the fire either by active firefighting or self-extinguishing due to exhaustion of fire load in that compartment. The compartments must be strictly sized as per NBC codes which have defined the range.

The entry and exit to a compartment must be fire rates same as the compartment walls of 1, 2 or 4 hours as the case may be. The fenestration or façade on the outer perimeter of the compartment must be able to resist fire for 2 hours or 1 hour depending on the building use type before it can spread to the adjacent or above compartment. However, in India, such strict regulations are not followed even if 8 out of 10 parameters are followed, fire will spread for the balance of two reasons not followed.

b) The list of such reasons can be, poorly rated compartment walls, non-fire-rated or underrated fire doors at exit and electrical ducts, improper electrical works and lack of knowledge of fire-rated electrical materials, absence of sprinkler system or poor design, cluttering of fire escape corridors, absence of fire lift, absence of refuge areas or inadequate provisions, inadequate open space for fire tender movement around the building, absence of smoke extraction system, absence or dysfunctional backup electrical system during fire emergencies, lack of understanding of fire rated façade materials, lack of vertical fire separation between compartments, absence of fire stops between floors at façade junctions and electrical ducts, inadequate fire escape widths of corridors and stairs, etc. The list is exhaustive and there many more reasons are there for the failure of fire safety

c) The remedial method is to have a fire safety consultant or an expert architect with holistic knowledge who understands each and every aspect of the planning and material behaviour during the fire and has knowledge of what can go wrong during a fire. When such a person has got on board during the planning and design of the building or project, most of the fire safety issues can be addressed.

A holistic approach is often missing when planning the fire safety of a building. An MEP and firefighting consultant can only advise for fire safety of services and their use in fighting fires. But when it comes to façade and fenestrations the expertise is lacking. Similarly, a façade consultant is lacking in knowledge about effective compartments and will focus only on the fire safety of the façade.

An architect, on the other hand, focuses on planning and aesthetic design. An expert who understands all the above aspects would be helpful in resolving most issues to create a fire-safe building. Every building is unique and there is no SOP that applies to all as they differ too much to have one rule to be applied uniformly across all buildings.