“Future Façades will be Much Advanced than We Have Ever Known”

Imagine being in a world that has its façade components 3d printed, dismantled, and reused in another project. A design to be generated through computational programming while incorporating passive designs and eco-friendly fabrication methods. High-performing façades with smart materials that can be responsive with their shape, properties, and orientation to act according to climate conditions.

It is Time for Design Customisation Based on Intelligent Data, Complex Requirements, and Regulative Constraints (Custom designed BIM/ Parametric)

The software can be used to automate repetitive tasks easily. You can use new software that has BIM, climatic analysis, and simulation all integrated into one place. BIM is the process adopted for years to replace the non-informative 3d models. It’s applied to provide information about cost, fabrication, and transportation data into the model. It also can be parametrized that you can change its profiles, angles, and heights in a matter of minutes. Design and estimation files are being standardized to be stored on cloud-based servers for broader access and better document management.

It ensures that the work is easily accessed, updated with the latest files, and seamlessly transitioning between project phases. In your next project, you won’t be making 3D modeling but you will be providing data also to analyze performance by computational tools like life assessment analysis through data sets integrated into the model. In Europe, we can witness more stringent building code requirements for energy performance are being applied with higher taxes.

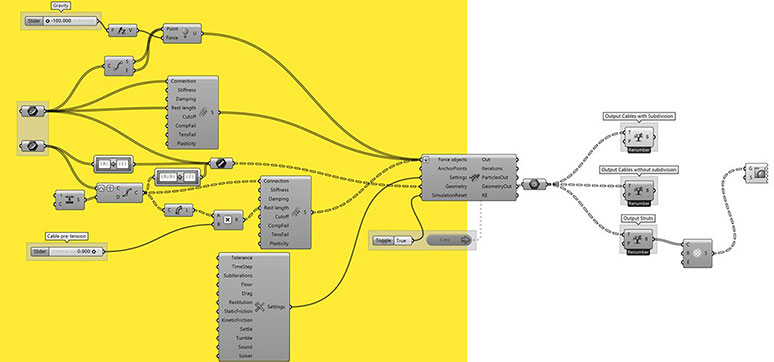

“Customising the existing software design through computer programming, scripts, and digital workflows to make a custom-made parametrized model”

What is next? The transition from conventional BIM to Parametric BIM

You will be able to have developed solutions through automated design processes, data structure, and machine learning techniques in your next project. The designers will derive the values of façade elements as functional algorithms through numerical and computational simulations. It’s an era of intelligent data that can be used to make parametrized scripts that can be added to Building information modeling. You can generate design forms in the beginning through the given intelligent data and design intent. It helps resolve discrepancies in a timely manner, reduces costs, and maintains accuracy. The design model can be updated automatically through all the parts when changes happen to a parameter. Documents or schedules can be generated automatically while designs can be fabricated in the same way with a great level of detail (at the level of individual building components).

“Conventional construction takes 15% of waste while modular construction is being pushed to reduce 3% net waste of material and energy.”

Modular construction can be built utilizing 3d printed parts that are finished or made in factories. It can reduce the overall manpower, transportation, and waste off-site while giving space to machines. That is better in terms of getting over labor shortage and project stoppage problems. Modular construction requires more design periods with challenging fabrication. Systems of modular construction can be dismantled and relocated with minimum impact elsewhere. IoT (internet of things) can trace these modules through sensors during shipping to the site and also give insights into the package’s humidity. We have to start fabrication of higher modules first then lower ones. The modular economy is achieved through the reuse and integration of building materials can save cost 30% than refurbishment. The standardization and repeatability of modules are crucial. Selecting local materials will help lower the embodied carbon (amount of energy required to extract, process, transport, install, and recycle a material).

“Future building material won’t be used to shield the user behind the envelope against climatic conditions but also to adapt with it while, when applicable, generates and saves energy”

Just as the trees change their leaves from season to season, façades can’t be designed as a constant and unchangeable shell anymore. It should be presented by dynamic adaptive models to the change of climate conditions easily (CABS: climatic adaptive building shells/façades). It adapts by changing its shapes such as smart materials of polymers, (SMA) shape memory alloy, and electrochromic glass. Recycled steel façades can adapt to any shape while having long-term durability. Engineers have started developing new eco-friendly residual materials such as coal ash as well.

Material selections in the future will be based on a lightweight, cradle to cradle, and EPD/LCA (life cycle assessment) ones. Façade material has an impact on the interior spaces for comfort and externally on the neighborhood aesthetics. Smart additives can be added to enhance façades acoustics and materials can be optimized to generate energy as well.

“Development of products like integrated ventilation system, closed cavity façades, CLT, and organic insulation is ongoing to meet the net-zero requirements. Automation of operable windows that are compacted, battery-powered, simply installed, and have low operation and maintenance costs. These are the key challenging customer buying criteria in the Middle East that are focusing on reducing cooling loads”.

By 2025, a rise in the use of wood as raw material and wood-based prefabricated construction is expected. Wood in form of CLT (cross-laminated timber) can capture carbon from the atmosphere.

Although it reduces production, it is being banned because of its combustibility. Envelope energy loads and glare can be controlled through building management software to optimize energy performance and meet sustainability goals. The future of a unitized compact double-skin façade is known as a closed cavity façade (CCF). It consists of a (DGU) at the interior with a single pane of glass at the exterior. Exterior conditions are monitored by solar shading devices and shading controls that are placed inside the cavity during assembly. It provides the thermal advantage of an exterior operable shading device without the high maintenance costs. To prevent dust and condensation, a small continuous flow of dry air is supplied into the cavity. Vertical green vegetation is being integrated into façades to boost noise absorption, pollution reduction, and well-being while reinforcing biodiversity and averring shade.

Future of Glass from Cradle to Gate, Into a Cradle to Cradle

The glass industry has challenges to be sustainable as it consumes a lot of energy for the panels to be heated, although the raw materials are too sustainable. Thus, glass manufacturers started thinking about alternatives to the production process to be more energy efficient. Also, secondhand glass markets are emerging in Europe (buy waste for new projects).

3D Printing is a Part of Robotic Construction Technologies that Have Developed with the Digital Turn in Architecture

3D printers are reliable, flexible, and an on-demand way to produce façade elements. It could be made through a smooth workflow with increased quality, limited waste, and on-demand manufacturing. After the pandemic has reassured us about crisis plans, 3D printing came to save us from being disrupted by material or labor shortages.

Robotic tech like drones can spray wet and dry affordable paint/mortar in high or difficult construction areas (instead of intensive scaffolding) including difficult geography like cliffs. For this, they use embedded AI systems developed by machine learning experts. Mobile Robotics can reinvent the whole construction process and its workflows while saving money and reducing safety risks in the long term.

Companies are collaborating with university labs on developing robots that can traverse rough terrains to monitor labor progress and scan construction sites. It gives a live feed of construction progress to international offices and reflects it on Project managers’ AR headsets/devices. The robot makes comparisons between as designed and asbuilt models while sending reports and updating 3D scanned models.

It also can survey with laser scanning for proper fixation points and updated coordinates for final fabrication drawings. Robotic arms can wrap and install panels post-fabrication. It can even lay bricks out into a stack to form walls. CAM (Computer-Aided Manufacturing) is the use of computer systems for planning, management, and control of the operations of a manufacturing fabrication using the interface directly or indirectly between the computer system and production resources.

How Far You Want to Go with 3D Printing in Your Building Envelope?

Everything can be 3D printed now based on 3d models no matter how complex it gets, new Engineering development will come to implement it for you. 3D printers can produce envelopes from small to large components or even a whole 3d printed envelope. 3D printers through 6 axis robotic arms (multi directions) are driving building construction to another level of detail. Software used to control the density of printed parts (fully dense or sparse fill). Polymerization, SAF (selective absorption fusion), and SIA (stereolithography) are the new techniques for 3d printing.

AM (additive) manufacturing was being used 30 years ago to enhance the efficiency of turbomachinery components. It can fill supply chain and stock gaps that affect the market lately. It is constantly developed to produce parametric façade forms that weren’t possible to be made before through using computer-aided design (CAD) or 3D object scanners while allowing for the creation of objects with precise geometric shapes. These geometries are built layer by layer, as with a 3D printing process, which is in contrast to traditional manufacturing that often requires machining or other techniques to remove surplus material.

Adapt Today Façades Requirements to the Structures of Yesterday

special glass type with interlayer mesh inside the IGU offers shade and meets the required u value to the building

As the most sustainable house is the one that hasn’t been built yet, the greenest building is the one that already exists. Thus, the need for retrofitting and renovation emerges. Retrofitting façades can be a result of the rapid change for existing buildings’ function.

It can be for adopting sustainable solutions without the need to redevelop the whole building sending old parts to waste. Tenants will be searching for retrofitting solutions to their aging building façades so they can maximize rental space value, meet the sustainability requirements/regulations (increase views of occupants, increase day-lighted spaces, monitor occupant well-being, and lower cooling/ heating loads), and adapt the latest techs for doing so.

Over cladding creates less than 40% embodied/ operation carbon than recladding approach. It can be made by adding interlayer/blinds while maintaining the building structure with minimal cost. You can retrofit by adding some heat chimneys and outlets to discard air and extract heat. Analysis of illuminance, sunlight, structure, energy prior to retrofitting to choose the best development possible with lower impact on occupants.

“We got to get back to Nature to lower our impact on it. Did you know that people spend 60-90% of their time surrounded by building envelopes and the building sector has 38% of global Co2 emissions?”

There is a growing demand in potential markets post-pandemic of beautiful façades that is efficient with general ventilation (cross-stacked) controlled by device integrated into façade openings and meeting acoustics performance (through noise concealers integrated into windows frame and through use of IGU-air gap). It should also achieve energy efficiency and zero-carbon emission sustainability requirements. Sustainable façades must perform better than normal ones in providing higher comfort with the least energy which can only be achieved by having climate-based design strategies (Including energy modeling, thermal comfort analysis, heat transfer analysis, heat and moisture analysis, and daylight analysis).

Through design optimization, important savings can be achieved. Especially material and energy savings, not only because of its economic advantages but also because of the ecological ones that have become, in the last decade, an essential factor to be considered in the project.

New Regulations and Standards are Changing to Certify Only Building with Net-Zero Energy Performance by 2050

Energy-generating elements integrated into façades aren’t enough to make energy-sufficient buildings. Thus, you have to lower your next project’s energy loads to meet sustainable energy requirements. Passive and bioclimatic solutions for cooling are a clear trend for building design to cut its carbon emission. A reduction of external heat gains is needed by interlayer films, low E coatings, building form (self-shading), infiltration (well-insulation opaque façades), and conduction (shading devices). Maximum use of daylight (light shelves or shading louvers), natural ventilation, and reduced SHG is needed instead of electricity consumption of artificial lighting and AC loads.

Sustainability requirements should adapt strategies in the early stages of design facilitating and reducing automation, low operation, and long-term maintenance costs in the Middle East. Façades with integrated nighttime cooling vents (in higher levels and with small sizes) reduce cooling load rates that are tripling since the ‘90s. It is powered by passive vents solutions and a higher air change rate. Heat control should be made by thermal breakers in frames and isolators in glass and gas insertion in IGU. Integrated transparent PVP into façades glass or louvers will be generating energy from façades as roofs of high-rise buildings aren’t enough to host them.

“Tenants will require firms to be LEED-certified or design complying with sustainability requirements in projects from now on”.

How You Can Better Position Your Firm for Growth?

The green sustainable building market is set to grow at an annual rate of 14.3 between 2020 and 2027. Next-generation of façades is going to be challenging for both designers and investors. More sustainable façades are needed that are highly effective on the value of buildings. Some scientists started searching for alternative smart materials. Advanced 3D building through simulation software is used for higher performance sustainable analysis in design early stages. Reuse of aluminum scraps in new façades. New regulations and taxes raised to state that by 2030, buildings should reduce their carbon emissions to 50%.

In 2050, there should be 100% building Net Zero certification. Even façade airtightness and orientation will be considered.

New Collaborations between Startups, Sub- Companies, and Scientific c/University Engineering Labs has Already Been Noticed in Last Year

Façade inspectors are being sent to assess the reasons behind emerging façade problems like moisture, fungus, and system failures. It’s not about who did it wrong, it’s about design efficiency and user comfort from the beginning that will affect the business reputation and unit prices in the long term. Every day we see new constraints, challenges, regulations, and technologies being implemented and integrated into our façade designing industry. A shift towards multidisciplinary firms of Façade engineers, computer scientists/programmers, environmental and sustainability consultants in one place to determine early decisions side by side with Architects. Collaborations of different firms and engineering labs are needed. Through it, you learn about harnessing products tech and its implementation. Integration of technologies, developing efficient software, and even digitized workflows in the façade industry.

What is next for the Façade Business in the Middle East?

In 2021, the façade industry saw drops in business due to major projects delays, material price increases, labor/material shortage, and working from home with curfew regulations while having city boundaries closure.

This year, it is expected to be driven by the NetZero sustainable buildings ideologies. It is very important to set your company ready for harnessing the emerging techs and the global business needs. It is an era for accurate, reliable, innovative, less risk-averse design which business owners should acknowledge clearly. Rapid urbanization as a result of the growing number of populations around the world will reflect on construction with vertical cities and high-rise building façades. Even structure systems like diagrids, exo-skeleton, and space trusses will evolve to host complex buildings.

Some countries in the Middle East just have started to deal with unitized curtain walls while others are dealing with challenging 3d printed and custom-made façades. In Europe, it is mostly about double-skin façades and in the USA is about IGUs. We could notice the direction of façade business in ME is mainly in Egypt nowadays. A transition of ME business hub accrued into Saudi Arabia as international fi rms’ headquarters is shifting from UAE to Saudi Arabia in order to contribute to the tremendous construction work that is planned in KSA.

“30% of business time is being reduced by using AI technology alone having machines to finish the required job efficiently while coordinating between office and site”

Tech revolutions will always affect the façade industry-shaping it a better future.

- Digitalised data and workflows through moving from storing data on local servers to cloud-based centralized data. It creates one source of façade models and documents which means different members can access the same model including all updates/changes that are being made in real-time. It would be changed to other users without the need to save and paste on the local server. Thus, a lot of enhancements to the submission process are being achieved. Also, the time spent by the different organizations on uploading, downloading, and searching for project information is being reduced as well as the stacked pdf printings. It also opens ways for the same team to work remotely.

- Combatting persistent labor shortage through the adoption of technologies like machine learning, data science, robotics, IoT, and AI to work.

- Façade management through Wearable XR/ AR headsets that can act as preliminary VMU models (before VMU and PMU installations). It shows façades with a real scale from digital to physical. PM can use it to make the integration between façade elements, give approvals, decide about design/specs changes, and detect system clashes in real-time. Tablets and phones are integrating the XR/AR technology in applications to replace headsets soon.

- BMU to replace scaffolding through BMU monorails, cradles, and mobile lifts that can be optimized and folded to access any part of the façade.

- 5G is needed for vital connectivity for the façade installer’s higher performance and better safety. WIFI gives coverage drop-off s because of metal obstruction while the mobile network gets out of coverages in distant sites. Façade installation and coordination through reliable, resilient 5G network instead of Wi-Fi are crucial for limitless wireless coverage needs of industrial settings as the operation and connection of advanced machines and devices on-site.

Future of Façade Industry Needs Nothing than Workers Mind Shift Today Not Later to be Ready with the Modern Innovative Workers

In 2021, there was a labor shortage that made room for technologies and automation to fill the gap while attracting new human talents into the field. By 2025, more than half of all current workplace profession tasks (repetitive with low rule) will be performed by machines in comparison to 29% only today. Future façades need innovative workers that adapt to digitalization acceleration while harnessing the latest techs.

They should be able to deal with the customized design requirements of each project (reducing wastage, innovation, and optimization of product quality) not only through the use of best-advanced machines or software. R&D departments are challenged for sustainability and environmental specialties. Designers can’t settle for existing knowledge for new hiring.

They need to obtain new skills like programming languages *python3 and C#) in order to make parametrized models coding and scripts of façade elements. Thus, each design should be made through different inputs.

A Lower number of drafters is expected and a large number of developers and creative scientists entering the field of façades. Procurement would have no more tedious tasks of manually counting supplies but instead, get correct numbers through software in a matter of minutes and save time and money. Based on recent surveys, one in four construction companies would go out of business if they made just two or three inaccurate estimates. Thus, estimation engineers need to enhance data and 3D models for proper estimation utilizing the latest software available.

Some new work regulations are adapting to distant working and part-time jobs. An employee can now work remotely or with more than one employer part-time. It makes the way for the next shift than an existing full-time job at the office.

Conclusion

The future is shifting façades from fancy-looking non-functional to climate and context-responsive ones. Façades are made by multidisciplinary teams of parametric designers, computer scientists working together with architects to foster the new generation of façade solutions. It could be made through technology, software development, in-depth research for new materials, and new fabrication techniques. Sustainable solutions, retrofitting, returning to adapting with nature, and compliance to regulations can get the world closer to its net-zero carbon targets while saving it from the global warming effects. Having new robotics technologies onto construction is changing the construction process.

The second generation of digital designs is ahead through the advancement of open-source programming-based software tools. It invites innovation and scripts writing. Interoperability of one software in another creates easier smooth digitized workflows, brings all the design and analysis features in one place, with the ability to real-time optimize and check.

The future of façade solutions can be made parallel with analysis and optimization to its performance in the early stage of design. Additive manufacturing, robotics, automation, and robotic fabrication processes through 3D printing can solve labor shortages while replacing the supply chain existing gaps of today. However, automation and digitization have been limited to medium to large scale companies which led some professions to disappear. So are you ready for the future?

The reason for the lack of digitization was not primarily the cost of hardware, but the need for specialized software to control specified tasks. It’s no longer considered a problem after offering open sources of programs. Cross-disciplinary efforts have also been hindered by the lack of clear task definitions, as skills are mostly passed down orally. We, therefore, consider digitization and robotics in combination with accessible software not only an efficiency-enhancing tool for the specialist but also as a way to preserve knowledge.